Yes, the primary function of a quality work boot is to provide superior traction, but their effectiveness is highly dependent on the design of the sole and the specific type of slippery surface you encounter. Most modern work boots feature slip-resistant outsoles specifically engineered to prevent falls in hazardous environments. However, not all slip-resistant technologies are created equal.

The term "slip-resistant" is not a universal guarantee of safety. True traction comes from correctly matching the boot's outsole material, tread pattern, and specific design features to the unique hazards of your work environment, whether that's water, oil, or ice.

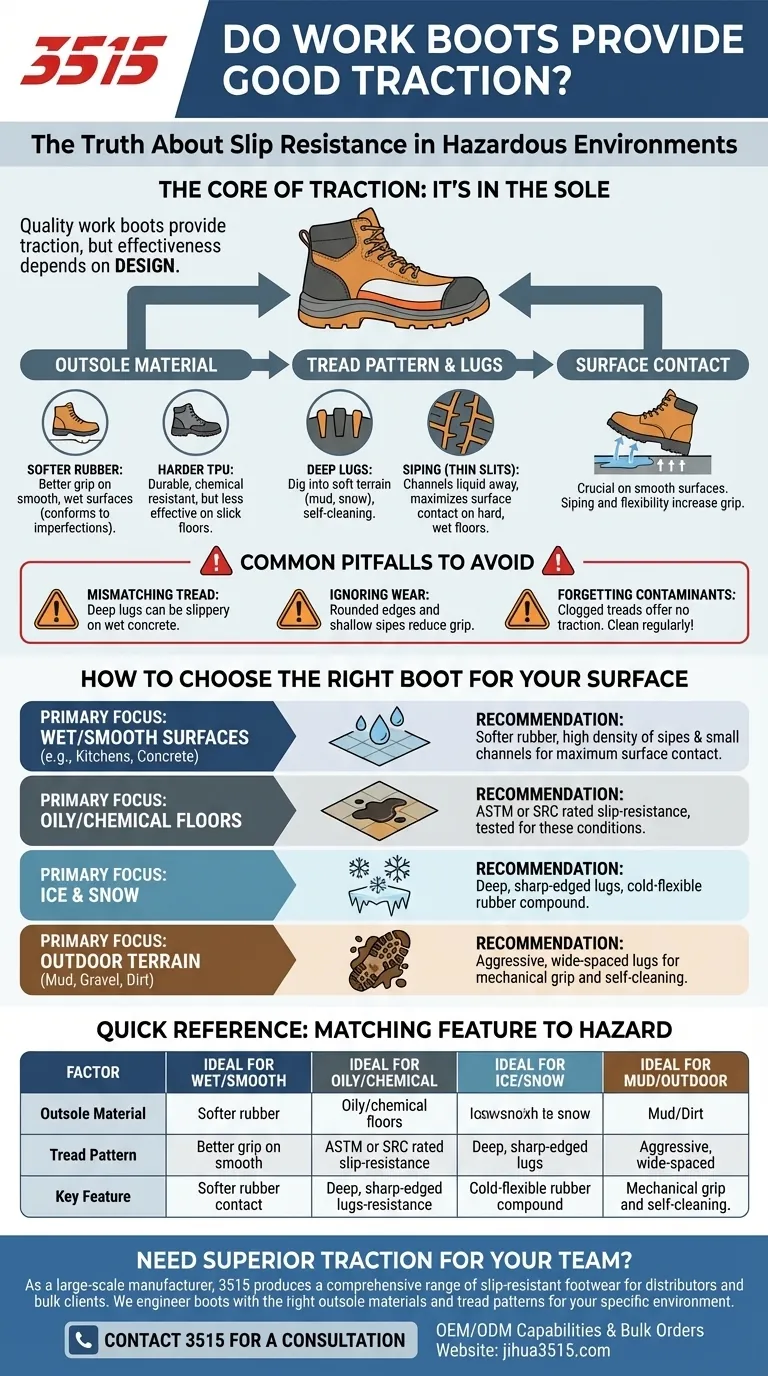

What Actually Creates Traction in a Work Boot?

Understanding the mechanics of a boot's outsole is the key to identifying genuine slip resistance. Three core elements work together to create a secure grip.

The Role of Outsole Material

The compound used for the outsole is your first point of contact with the ground. Softer rubber compounds generally offer a better grip on smooth, wet surfaces because they can conform more effectively to microscopic imperfections in the flooring.

Harder materials like Thermoplastic Polyurethane (TPU) offer superior durability and resistance to chemicals but can be less effective on slick indoor floors.

Understanding Tread Patterns and Lugs

The pattern on the bottom of your boot is not for aesthetics; it's a functional system. Lugs are the deep indentations and protruding blocks that define the tread.

Deep, widely-spaced lugs are designed for soft surfaces like mud, snow, or gravel. They dig into the terrain for grip and are self-cleaning, shedding debris so the tread doesn't get clogged.

The Importance of Surface Contact

Conversely, on smooth, hard surfaces covered in water or oil, you need maximum surface contact. Many boots designed for these conditions feature siping—thin, razor-like slits in the outsole lugs.

These tiny channels flex open under pressure, increasing the sole's surface area and pushing liquids away from the point of contact, much like the tread on a high-performance car tire.

Common Pitfalls to Avoid

Choosing the wrong boot for the environment can create a false sense of security and may even increase your risk of a fall.

Mismatching the Tread to the Surface

A boot with deep, aggressive lugs designed for outdoor terrain can be surprisingly slippery on a smooth, wet concrete floor. The large lugs reduce the amount of surface area in contact with the floor, compromising grip.

Ignoring the Impact of Wear

Traction is not permanent. As a boot's outsole wears down, the sharp edges of the tread pattern become rounded and the water-channeling sipes become shallow. This significantly reduces the boot's ability to provide a secure grip.

Forgetting About Contaminants

The best tread pattern in the world is useless if it's clogged. Mud, sawdust, or other debris can fill the channels in your outsole, effectively creating a smooth, flat surface with no traction. Regular cleaning is essential for maintaining grip.

How to Choose the Right Boot for Your Surface

Focus on the specific hazard you face most often to make the most effective choice.

- If your primary focus is wet, smooth surfaces (e.g., kitchens, concrete floors): Look for boots with softer rubber outsoles and a high density of small channels or siping to maximize surface contact and channel water away.

- If your primary focus is ice and snow: Prioritize boots with deep, sharp-edged lugs and a rubber compound specifically designed to stay flexible in cold temperatures.

- If your primary focus is oily or chemical-covered floors: Seek out boots with an explicit ASTM or "SRC" slip-resistance rating, as these are tested specifically for these challenging conditions.

- If your primary focus is outdoor terrain (mud, gravel, dirt): Choose boots with aggressive, wide-spaced lugs that provide excellent mechanical grip and shed debris easily.

Selecting the right work boot is an essential act of risk assessment, not just a purchase.

Summary Table:

| Factor | Ideal for Wet/Smooth Surfaces | Ideal for Oily/Chemical Floors | Ideal for Ice/Snow | Ideal for Mud/Outdoor Terrain |

|---|---|---|---|---|

| Outsole Material | Soft, flexible rubber | ASTM/SRC-rated rubber | Cold-temperature flexible rubber | Durable rubber or TPU |

| Tread Pattern | High density of sipes & small channels | Tested for oil/grease resistance | Deep, sharp-edged lugs | Wide-spaced, aggressive, self-cleaning lugs |

| Key Feature | Maximizes surface contact, channels water | Certified slip resistance | Mechanical grip, prevents snow buildup | Debris shedding, deep penetration |

Need Work Boots with Superior Traction for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, engineered with the right outsole materials and tread patterns for your specific work environment.

We help you mitigate workplace risks and enhance safety with boots designed for genuine slip resistance. Let's discuss your requirements and find the perfect solution for your customers or workforce.

Contact 3515 today for a consultation to explore our OEM/ODM capabilities and bulk order options.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What types of jobs commonly use PVC work boots? Essential Protection for Wet & Demanding Work

- What is the difference between chemical resistance and chemical proof in work boots? Choose the Right Protection

- Are PVC boots used in outdoor work involving wet terrain? A Guide to Choosing the Right Work Boot

- What are the practical reasons for the popularity of cowboy boots as work attire? Unmatched Durability & Protection

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Why is sole material important in work boots? Unlock the Key to Safety, Comfort & Durability

- What health benefits are associated with wearing cowboy boots? Improve Posture & Ankle Support

- What should you look for in puncture-resistant work boots to ensure compliance? Verify the ASTM F2413 'PR' Label