To ensure a work boot is compliant for puncture resistance, you must check the interior label for an official ASTM rating. Specifically, look for the ASTM F2413 standard followed by a 'PR' designation, which confirms it meets the industry requirement for protecting your feet from sharp objects underfoot.

The compliance label inside the boot is your objective proof of protection. While puncture resistance ('PR') is a critical feature, true safety comes from matching the boot's full set of certified protections to the specific hazards you face on the job.

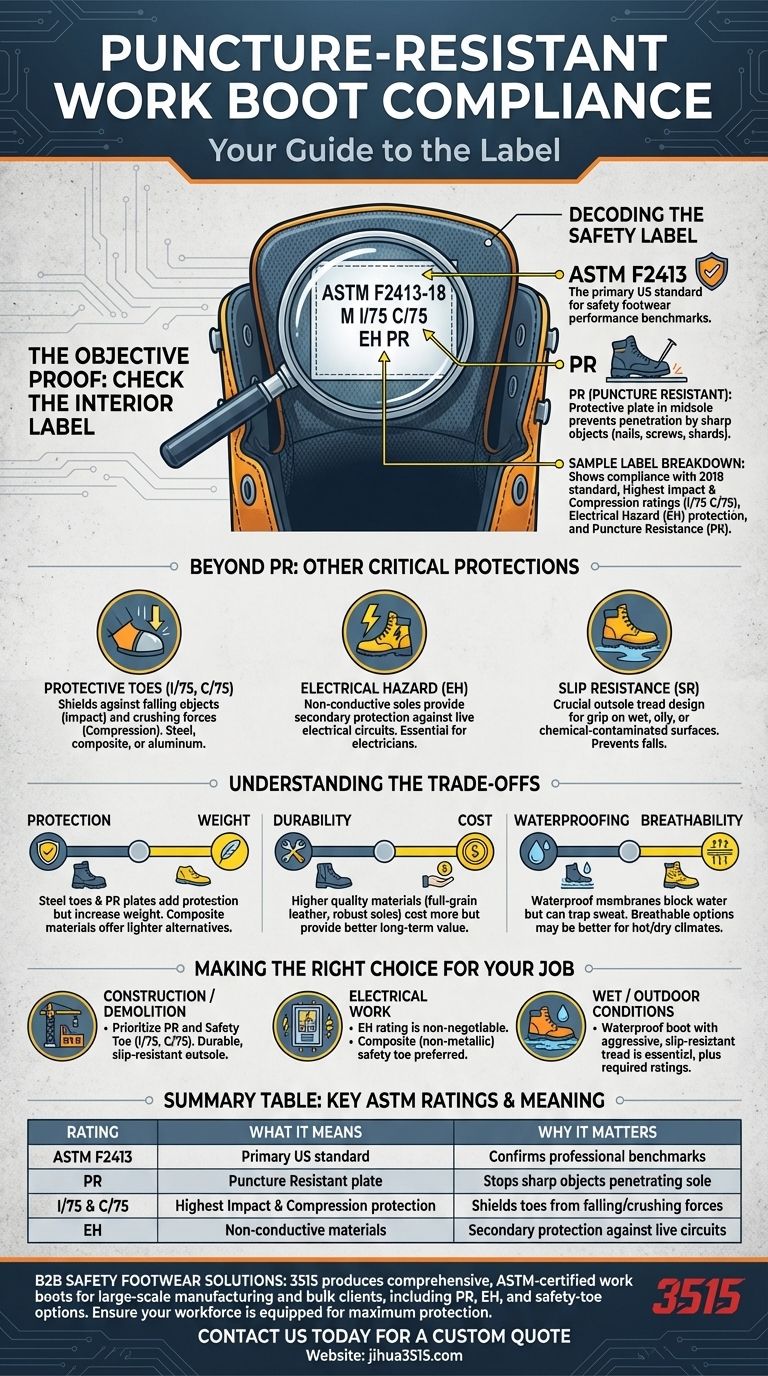

Decoding the Safety Label: Your Guide to Compliance

The most important step in choosing a compliant boot is learning to read its safety label. This tag, typically found on the interior of the tongue, is a concise summary of the boot's tested capabilities according to a national standard.

The ASTM F2413 Standard

The primary standard for safety footwear in the United States is ASTM F2413. This specification outlines the minimum requirements for performance in several key areas. When you see this on a label, you know the boot has been tested to a professional benchmark.

The 'PR' Designation

The 'PR' marking specifically indicates the boot is puncture-resistant. This means a protective plate has been built into the midsole, directly under your foot. This plate is designed to prevent sharp objects like nails, screws, or metal shards from penetrating the sole.

How to Find and Read the Label

Look inside the boot for a sewn-in tag. It will have a clear, multi-line format. A typical label for a fully-featured boot might look like this:

ASTM F2413-18 M I/75 C/75 EH PR

This tells you the boot meets the 2018 version of the standard, has the highest-rated impact and compression resistance for its safety toe, and is also certified for Electrical Hazard and Puncture Resistance.

Beyond Puncture Resistance: Other Critical Protections

While 'PR' is your focus, other common ASTM ratings are essential for ensuring comprehensive safety in different environments. Understanding them will help you make a more informed choice.

Protective Toes (Impact & Compression)

The 'I/75' and 'C/75' ratings refer to the safety toe cap. This feature protects your toes from falling objects (impact) and crushing forces (compression). Safety toes can be made of steel, lighter-weight composite materials, or aluminum.

Electrical Hazard (EH)

An 'EH' rated boot is manufactured with non-conductive, shock-resistant soles and heels. It provides a secondary source of protection against accidental contact with live electrical circuits, which is a critical feature for electricians and maintenance workers.

Slip Resistance (SR)

While not always part of the main ASTM line, slip resistance is a vital feature. The design of the outsole tread is crucial for maintaining grip on surfaces contaminated with water, oil, or chemicals. A good tread helps prevent falls on ladders and slick floors.

Understanding the Trade-offs

Selecting the right boot always involves balancing competing factors. Being aware of these trade-offs will help you prioritize what matters most for your work.

Protection vs. Weight

Features like steel toes and puncture-resistant plates add significant protection but also increase the boot's weight. For jobs requiring constant walking, lighter composite materials may reduce fatigue without sacrificing compliance.

Durability vs. Cost

Higher-quality materials like full-grain leather and more robust sole constructions often come with a higher price tag. However, they typically provide better long-term durability, comfort, and protection, making them a worthwhile investment.

Waterproofing vs. Breathability

A fully waterproof boot is essential for wet job sites, but the membrane that blocks water can also trap sweat. In hot and dry climates, a more breathable, non-waterproof boot may provide greater all-day comfort.

Making the Right Choice for Your Job

Use the safety label to confirm compliance, then consider your specific work environment to select the right combination of features.

- If your primary focus is construction or demolition: Prioritize boots with 'PR' and a safety toe ('I/75', 'C/75') along with a durable, slip-resistant outsole.

- If your primary focus is electrical work: An 'EH' rating is non-negotiable, and a composite (non-metallic) safety toe is often preferred.

- If your primary focus is working in wet or outdoor conditions: A waterproof boot with an aggressive, slip-resistant tread is essential, in addition to any other required safety ratings.

Trust the label to verify compliance, but trust your understanding of the job to select the right protection.

Summary Table:

| Key ASTM Rating | What It Means | Why It Matters |

|---|---|---|

| ASTM F2413 | The primary US standard for safety footwear. | Confirms the boot meets professional safety benchmarks. |

| PR (Puncture Resistant) | A protective plate in the midsole stops sharp objects. | Prevents nails, screws, or shards from penetrating the sole. |

| I/75 & C/75 | Highest-rated protection for impact and compression on the toe. | Shields toes from falling objects and crushing forces. |

| EH (Electrical Hazard) | Boot is made with non-conductive, shock-resistant materials. | Provides secondary protection against live electrical circuits. |

Ensure your workforce is equipped with fully compliant, high-performance safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of puncture-resistant, electrical hazard, and safety-toe boots designed for maximum protection and durability. Contact us today to discuss your specific needs and receive a custom quote.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are inlays and stitching used for in cowboy boots? From Function to Fashion

- What are the different types of heels in cowboy boots? Choose the Right Heel for Riding or Walking

- What is the traditional material used for cowboy boots? Discover the Durable Legacy of Cowhide

- How do different shank materials compare in work boots? Choose the Right Support for Your Job

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- Why is leather conditioner not recommended for frequent use on boots with membrane-constructed materials?

- Is it advisable to buy cowboy boots online? The Critical Fit Guide for First-Time Buyers

- What is the primary threat to cowboy boots and how can it be combated? Protect Your Investment