The sole of a work boot is far more than a simple layer of rubber. It is an engineered system designed to be the critical interface between you and your work environment. Its material and design dictate your safety, comfort, and endurance by providing specialized protection, traction, and support tailored to specific hazards and surfaces.

The most important thing to understand is that there is no single "best" sole. The optimal choice is entirely dependent on your primary work environment, as the sole's design directly trades certain capabilities for others—such as grip on loose terrain versus stability on hard concrete.

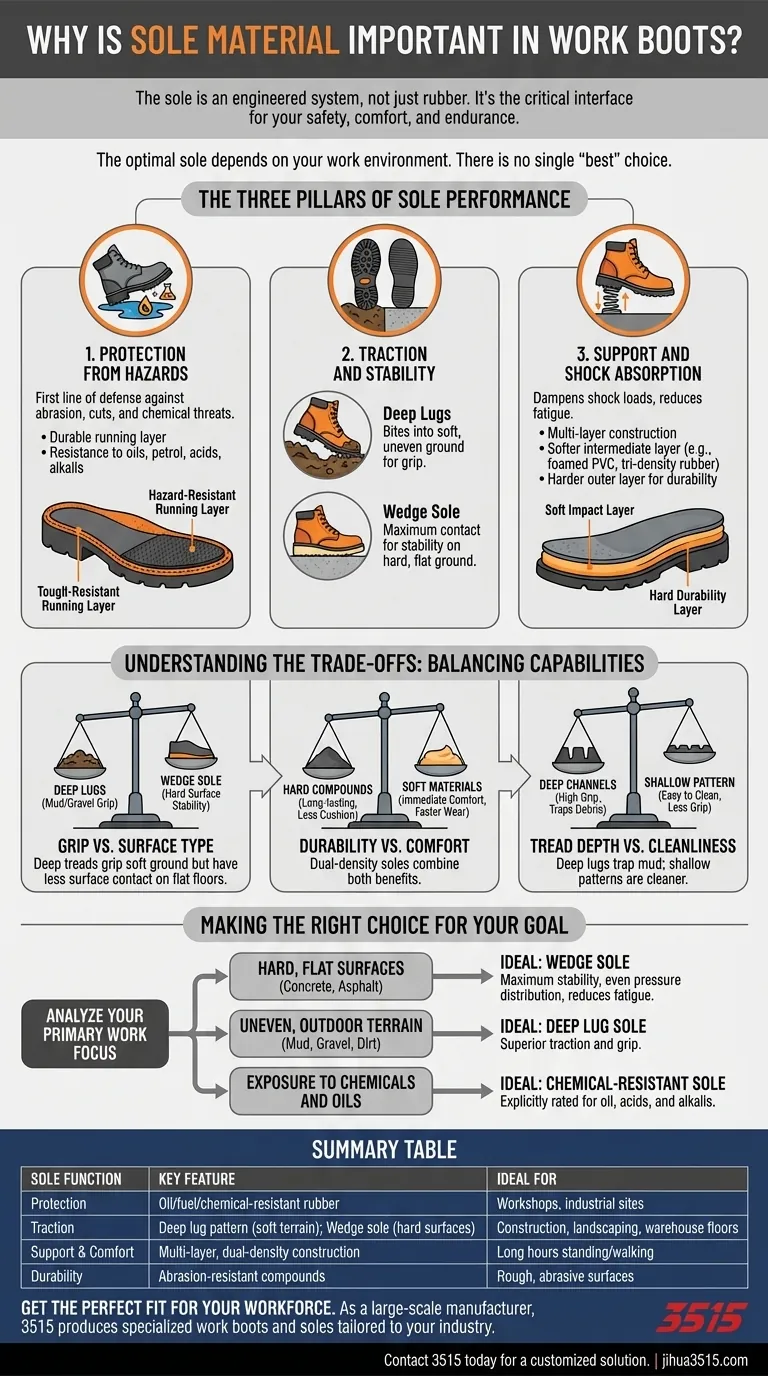

The Three Pillars of Sole Performance

A work boot's sole serves three primary functions. The effectiveness of each is determined by its material composition and structural design.

Protection from Hazards

The outermost layer of the sole, often called the running layer, is your first line of defense. It must be durable enough to withstand abrasion and deformation from rough surfaces.

For specialized environments, materials are chosen for their resistance to specific threats. This includes resistance to oils, petrol, acids, and alkalis, which can degrade standard rubber and compromise both the boot's integrity and your safety.

Traction and Stability

Traction is essential for preventing slips and falls. The sole's ability to grip a surface depends on its material and, most importantly, its tread design.

A sole with deep treads or "lugs" is designed to bite into soft, uneven surfaces like mud, gravel, or dirt. Conversely, a wedge sole with a shallow tread pattern provides maximum surface contact on hard, flat ground like concrete or asphalt, ensuring superior stability.

Support and Shock Absorption

Standing or walking for long hours creates significant impact on your joints. A high-quality sole is engineered to dampen these shock loads, reducing fatigue.

This is often achieved with a multi-layer construction. An intermediate layer of softer material, like foamed polyvinyl chloride or tri-density rubber, absorbs impact, while the harder outer layer provides durability. This combination delivers both comfort and resilience.

Understanding the Trade-offs

Choosing the right sole involves recognizing its inherent compromises. A design that excels in one area often does so at the expense of another.

Grip vs. Surface Type

A sole with a deep, aggressive lug pattern that is excellent in mud can be less stable on a smooth, flat floor because less surface area is making contact with the ground.

A flat wedge sole, which provides superior stability on concrete, offers very little grip on loose gravel or in deep mud.

Durability vs. Comfort

Extremely hard, durable sole compounds can last for years but may offer less shock absorption, leading to greater fatigue.

Softer, more cushioned materials provide immediate comfort but may wear down more quickly under abrasive conditions. This is why dual-density soles are so effective, as they combine the benefits of both.

Tread Depth vs. Cleanliness

The deep channels of a lug sole are highly effective at providing grip but can easily trap mud and debris, which can be tracked into vehicles or finished indoor spaces.

The shallow pattern of a wedge sole is incredibly easy to clean, making it a preferred choice for environments where cleanliness is a factor.

Making the Right Choice for Your Goal

Your decision should be dictated entirely by the demands of your job. Analyze your daily tasks and the surfaces you encounter most frequently.

- If your primary focus is working on hard, flat surfaces (concrete, asphalt): A wedge sole provides maximum stability and even pressure distribution to reduce foot fatigue.

- If your primary focus is navigating uneven, outdoor terrain (mud, gravel, dirt): A sole with a deep, aggressive tread pattern (lug sole) is essential for superior traction and grip.

- If your primary focus is exposure to chemicals and oils: Look for soles explicitly rated for resistance to oil, acids, and alkalis to ensure durability and safety.

Investing in the right sole is an investment in your daily safety and long-term physical well-being.

Summary Table:

| Sole Function | Key Material/Design Feature | Ideal For |

|---|---|---|

| Protection | Oil/fuel/chemical-resistant rubber | Workshops, industrial sites |

| Traction | Deep lug pattern (soft terrain); Wedge sole (hard surfaces) | Construction, landscaping, warehouse floors |

| Support & Comfort | Multi-layer, dual-density construction | Long hours standing/walking |

| Durability | Abrasion-resistant compounds | Rough, abrasive surfaces |

Get the Perfect Fit for Your Workforce

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized work boots and soles, engineered to meet the specific demands of your industry and workforce.

Let us help you equip your team with boots that deliver unmatched safety, all-day comfort, and long-lasting value.

Contact 3515 today for a customized solution and quote!

Visual Guide

Related Products

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Are there any exceptions to the sole requirement for wildland fire boots? The Alaskan Exemption Explained

- How does flexibility compare among PVC, neoprene, and rubber work boots? Find Your Perfect Fit for All-Day Comfort

- How should work boots with zips be cared for? Extend Boot Life with Proper Zip Maintenance

- How should motorcycle boots fit for optimal use? A Guide to Safety and Comfort

- Why is traction an essential feature in work boots? Prevent Slips and Ensure Workplace Safety

- What are the different types of boot toes available? Choose the Right Toe for Your Job

- What construction methods are used in high-quality engineer boots? A Guide to Boots That Last a Lifetime

- What are the advantages of non-safety toe work boots? Boost Comfort & Reduce Fatigue