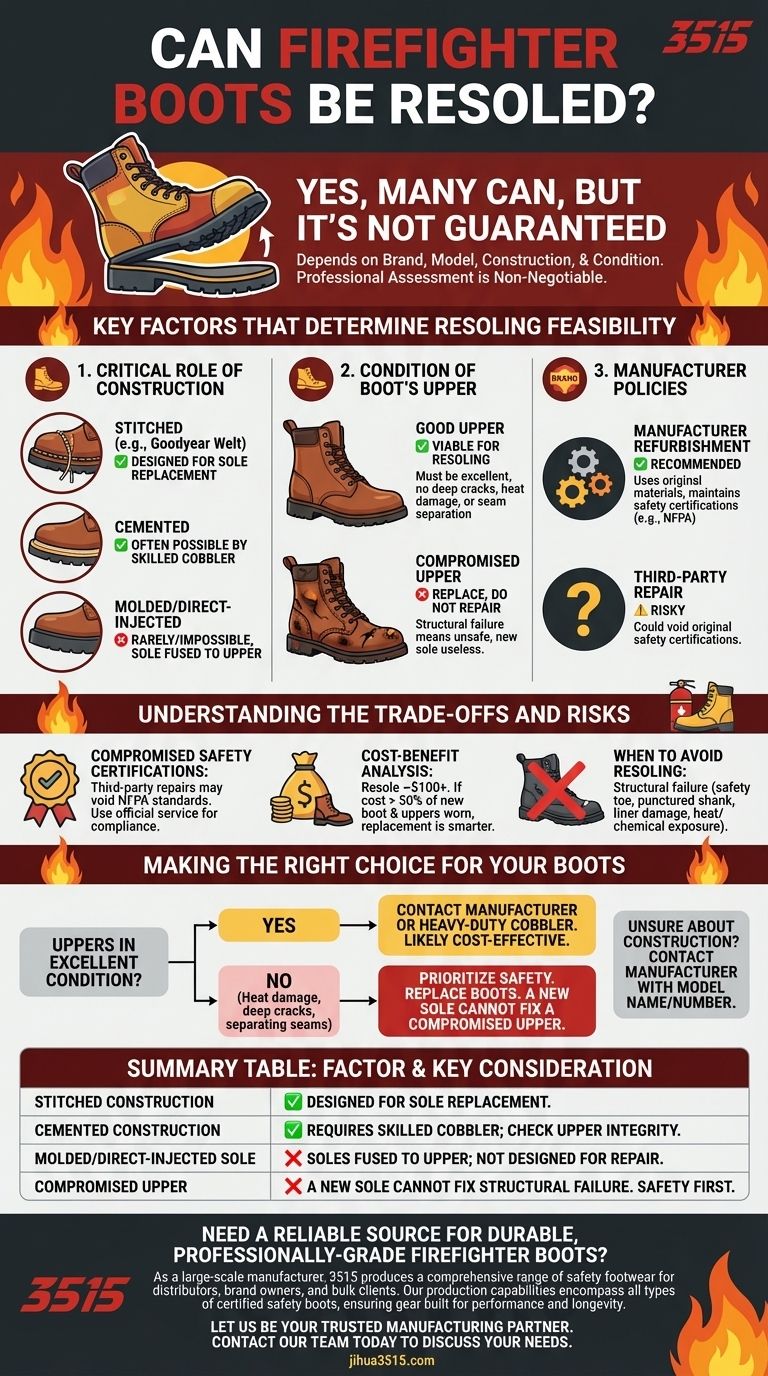

Yes, many firefighter boots can be resoled, but it is not a universal guarantee. The possibility depends entirely on the boot's specific brand, model, construction method, and its overall condition. For safety-critical equipment like this, a professional assessment is non-negotiable.

The core issue isn't just whether a new sole can be attached, but whether the rest of the boot remains structurally sound and safe for duty. Resoling is only viable if the boot's upper components are in excellent condition and the construction method allows for it.

Key Factors That Determine Resoling Feasibility

The decision to resole a boot goes far beyond the condition of the tread. Several interconnected factors determine whether a repair is practical and, more importantly, safe.

The Critical Role of Construction

A boot's construction is the primary factor. Boots with stitched soles, like a Goodyear welt, are specifically designed for the sole to be removed and replaced without damaging the upper.

Many high-end firefighter boots use a cemented construction, where the sole is attached with a powerful adhesive. These can often be resoled by a skilled cobbler who can properly heat, remove, and re-bond a new sole.

However, some boots feature molded or direct-injected soles, which are fused directly to the upper. These are almost always impossible to resole.

The Condition of the Boot's Upper

A new sole is useless if the rest of the boot is failing. Before considering a resole, an expert must inspect the boot's upper—the leather or synthetic material that covers the foot.

Look for deep cracks, heat damage, separated seams, or excessive wear. If the structural integrity of the upper is compromised, the boot should be replaced, not repaired.

Manufacturer and Brand Policies

Many reputable manufacturers of firefighter gear offer their own resoling or complete refurbishment services. This is often the best option, as they use original materials and processes that maintain the boot's safety certifications.

Consulting the manufacturer or the retailer where you bought the boots is the most reliable first step.

Understanding the Trade-offs and Risks

Resoling is a cost-effective way to extend the life of expensive gear, but it's crucial to weigh the benefits against the potential risks, especially for professional use.

Compromised Safety Certifications

Firefighter boots must meet specific safety standards (like those from the NFPA). A third-party repair could potentially void the boot's original certification. Using a manufacturer's official repair service is the safest way to ensure compliance.

The Cost-Benefit Analysis

A professional resole can cost around $100 or more, depending on the work required. If this amount is more than half the cost of a new pair of boots, and the uppers show significant wear, replacement is often the smarter financial decision.

When to Absolutely Avoid Resoling

Do not resole a boot if it has any signs of structural failure. This includes damage to the safety toe, a punctured shank, a compromised waterproof liner, or any evidence of the upper being exposed to extreme heat or chemicals. A new sole cannot fix these fundamental safety flaws.

Making the Right Choice for Your Boots

Use these guidelines to determine your next step.

- If your boot's uppers are in excellent condition: Resoling is likely a cost-effective option, and you should start by contacting the manufacturer or a cobbler who specializes in heavy-duty work boots.

- If your boot shows signs of heat damage, deep cracks, or separating seams: You must prioritize safety and replace the boots, as a new sole cannot fix a compromised and unsafe upper.

- If you are unsure about your boot's construction: Contact the manufacturer directly with the model name or number; they can provide a definitive answer on whether it was designed to be resoled.

Ultimately, a professional assessment is the only way to ensure you are safely and effectively extending the life of your most critical gear.

Summary Table:

| Factor | Can Be Resoled? | Key Consideration |

|---|---|---|

| Stitched Construction (e.g., Goodyear Welt) | ✅ Yes | Designed for sole replacement. |

| Cemented Construction | ✅ Often | Requires skilled cobbler; check upper integrity. |

| Molded/Direct-Injected Sole | ❌ Rarely | Soles are fused to the upper; not designed for repair. |

| Compromised Upper (Cracks, Heat Damage) | ❌ No | A new sole cannot fix structural failure. Safety first. |

Need a reliable source for durable, professionally-grade firefighter boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety boots, ensuring you get gear built for performance and longevity.

Let us be your trusted manufacturing partner. Contact our team today to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How does increasing carbon fiber content impact protective footwear insoles? Optimize Performance and Support

- How should professional functional footwear, such as safety shoes and tactical boots, be optimized based on load-bearing gait research? For Enhanced Stability & Performance

- What role do integrated force plates play in the performance testing of safety footwear? Biomechanical Analysis Experts

- What is the minimum order quantity for oil resistant safety boots? Navigate MOQs from 100 to 1,000 Pairs

- What core protection functions do industrial-grade Safety Shoes provide during drilling and blasting in a quarry?

- How often should work shoes be replaced for those who stand all day? Protect Your Joints and Prevent Pain

- What standards must protective footwear meet? A Guide to ASTM F2413 and F2412 Compliance

- What are the key OSHA regulations for safety footwear? Ensure Compliance & Protect Your Workforce