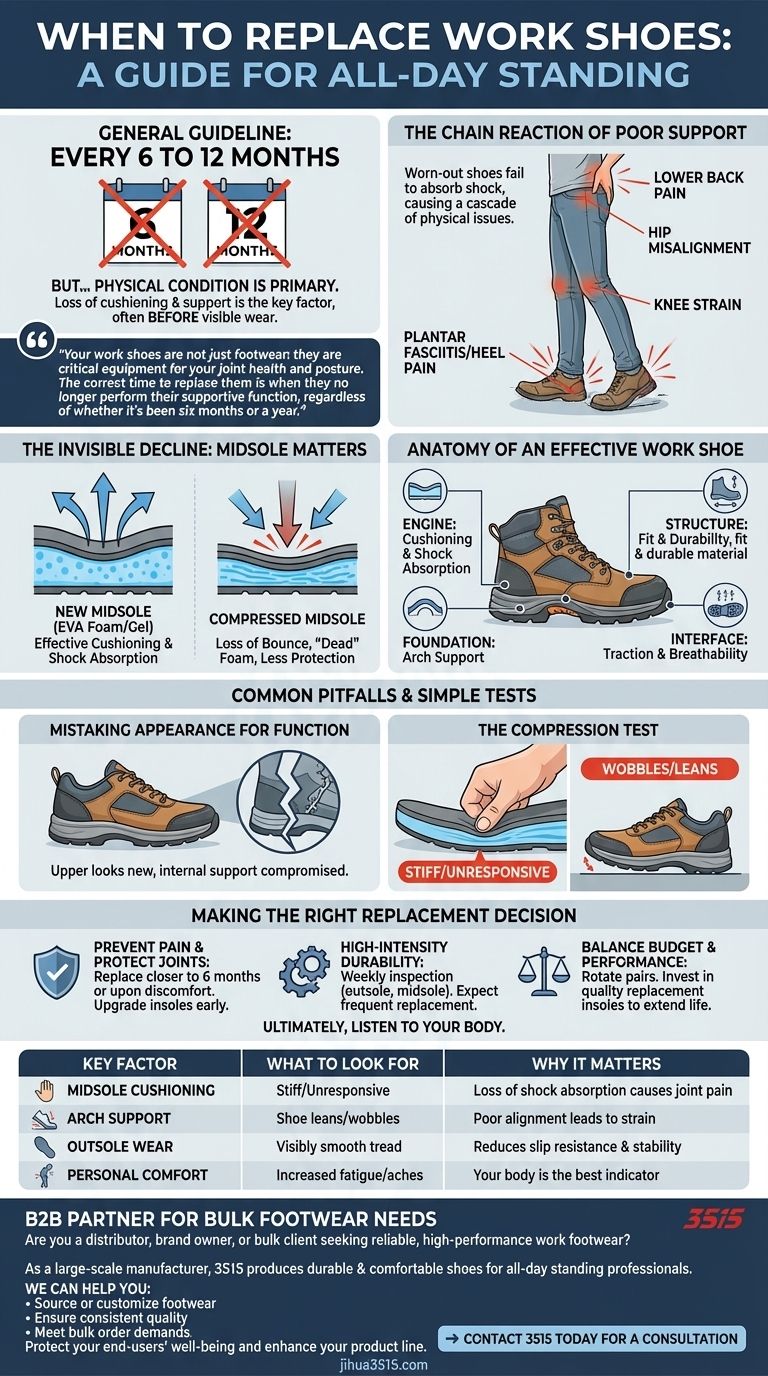

As a general guideline, work shoes for those who stand all day should be replaced every 6 to 12 months. However, this calendar-based estimate is secondary to the actual physical condition of the shoe. The most important factor is the loss of cushioning and support, which often degrades long before the shoe appears visibly worn out.

Your work shoes are not just footwear; they are critical equipment for your joint health and posture. The correct time to replace them is when they no longer perform their supportive function, regardless of whether it's been six months or a year.

Why Your Shoes Are a Foundational Tool

Proper footwear is the base of support for your entire body. When you stand for hours, the impact on your feet radiates upward, affecting your alignment, comfort, and energy levels.

The Chain Reaction of Poor Support

Worn-out shoes fail to absorb shock and distribute your body weight evenly. This initial failure in the feet can lead to a cascade of physical issues.

This strain often manifests as plantar fasciitis or general heel pain first. It then travels up to the knees, hips, and lower back as your body tries to compensate for the lack of stable alignment.

The Invisible Decline

The most critical part of your shoe, the midsole, is typically made of foam like EVA. This component is responsible for cushioning and shock absorption.

This foam compresses with every step. Over time, it loses its ability to bounce back, even if the outer part of the shoe still looks good. This "dead" midsole provides significantly less protection for your joints.

The Anatomy of an Effective Work Shoe

Understanding what makes a good shoe helps you know what to look for when buying a new pair and what to inspect for signs of wear on your current pair.

The Engine: Cushioning and Shock Absorption

The midsole is the engine of the shoe. Materials like EVA foam or gel are designed to absorb the impact of standing on hard surfaces, reducing pressure on your feet and joints.

The Foundation: Arch Support

Proper arch support ensures your foot is in its correct anatomical position. This helps distribute weight properly and prevents the muscle fatigue that comes from an unstable footing.

The Structure: Fit and Durability

A shoe must be built from high-quality, durable materials to withstand daily wear. It also needs a lightweight design to reduce fatigue and sufficient toe room to prevent cramping and discomfort over a long shift.

The Interface: Traction and Breathability

A slip-resistant outsole provides critical traction on various surfaces, preventing accidents. At the same time, breathable materials like mesh or full-grain leather help manage moisture and keep your feet comfortable.

Common Pitfalls to Avoid

Simply buying expensive shoes or replacing them on a strict schedule isn't enough. Awareness of common mistakes is key to getting the best results.

Mistaking Appearance for Function

The most common error is judging a shoe by its cover. The upper may be clean and the laces intact, but the internal support structure could be completely compromised.

The Compression Test

A simple way to check the midsole is to press your thumb into it. If it feels stiff and doesn't compress easily, the cushioning is likely worn out. You can also place the shoe on a flat surface to check if it wobbles or leans to one side, indicating uneven wear.

Ignoring the Role of Insoles

The insoles that come with most work shoes are basic placeholders. Investing in high-quality insoles can dramatically enhance arch support and cushioning, customizing the shoe to your specific foot shape.

Making the Right Replacement Decision

Your approach should be tailored to your specific work environment and physical needs. Use these guidelines to make an informed choice.

- If your primary focus is preventing pain and protecting your joints: Replace your shoes closer to the 6-month mark or as soon as you feel a decline in comfort, and consider upgrading the insoles from day one.

- If your primary focus is durability in a high-intensity environment: Inspect your shoes weekly for signs of wear, especially on the outsole tread and midsole cushioning, and be prepared to replace them more frequently than every six months.

- If your primary focus is balancing budget with performance: Extend the life of your shoes by rotating between two pairs and investing in high-quality replacement insoles, which can restore support for a lower cost than new shoes.

Ultimately, listening to your body is the most reliable indicator for when a change is needed.

Summary Table:

| Key Factor | What to Look For | Why It Matters |

|---|---|---|

| Midsole Cushioning | Press with thumb; feels stiff/unresponsive | Loss of shock absorption causes joint pain |

| Arch Support | Shoe leans or wobbles on a flat surface | Poor alignment leads to foot, knee, and back strain |

| Outsole Wear | Tread is visibly smooth, especially on heels | Reduces slip resistance and stability |

| Personal Comfort | Increased foot or leg fatigue, new aches | Your body is the best indicator of failing support |

Are you a distributor, brand owner, or bulk client seeking reliable, high-performance work footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and comfortable shoes and boots designed for professionals who stand all day. Our production capabilities encompass all types of work footwear, ensuring your customers or employees have the critical support they need.

We can help you:

- Source or customize footwear with superior cushioning and arch support.

- Ensure consistent quality and durability for high-intensity environments.

- Meet bulk order demands with reliable manufacturing scale.

Protect your end-users' well-being and enhance your product line with footwear built to last.

➡️ Contact 3515 today for a consultation to discuss your specific needs and how we can support your business.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What materials are used in composite toes for oil-resistant safety boots? Discover the Non-Metallic Advantage

- What is the primary function of an IMU in construction safety footwear? Enhancing Real-Time Worker Protection

- Why is professional functional protective footwear considered a core component for the prevention of diabetic foot ulcers?

- Why is the anti-smash feature essential in palm oil processing areas? Ensure Worker Safety from Heavy Machinery Risks

- Why are safety shoes considered a core identification target in industrial monitoring? Boosting AI Compliance

- Why are high-breathability and high-elasticity composite fabrics used in protective shoes for diabetic foot care?

- What is the primary function of professional Safety Shoes during the epoxy resin application phase of wind turbine blade manufacturing? Your Chemical Defense Shield

- What are the OSHA requirements for safety footwear? A Guide to Compliance & ASTM Standards