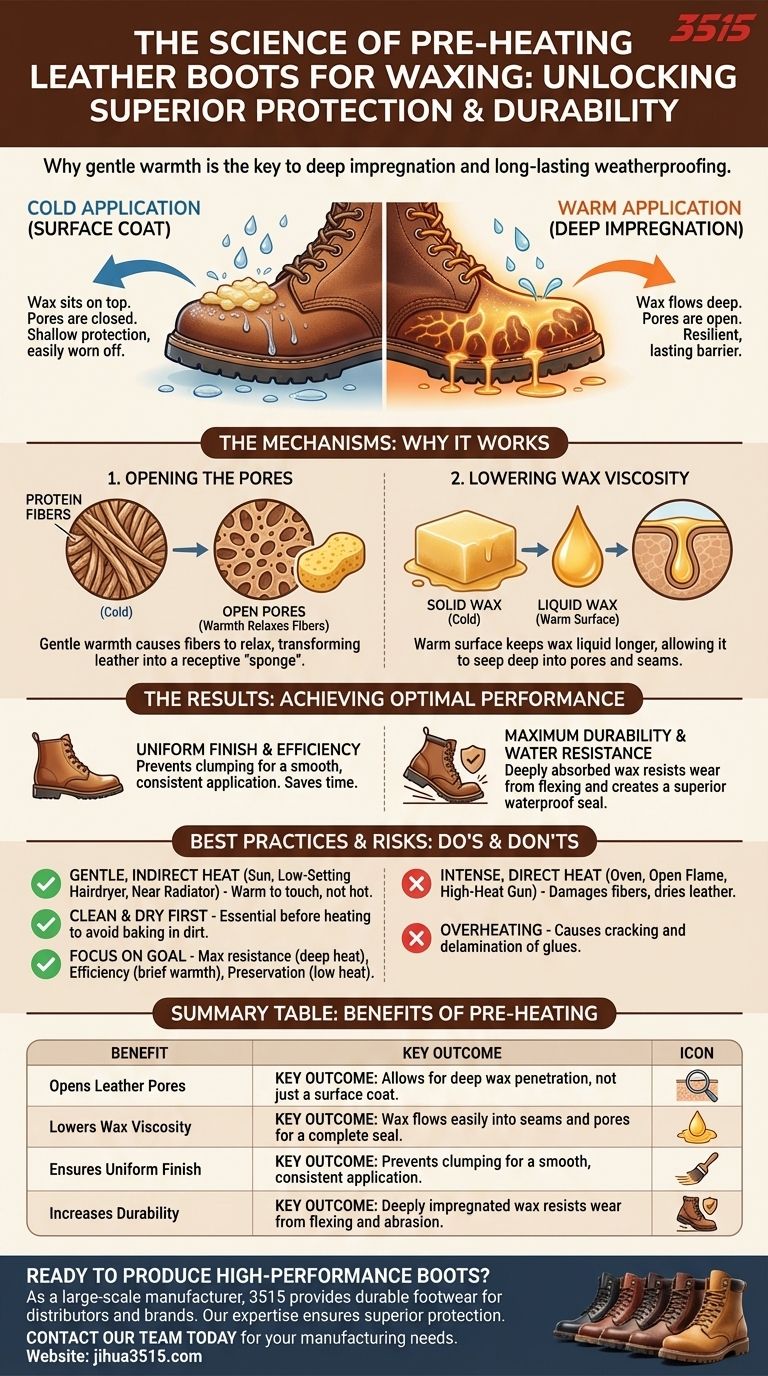

The primary benefit of pre-heating your boots is to temporarily open the pores of the leather. This simple preparation allows the wax to penetrate more deeply into the material, rather than just sitting on the surface, which results in a more durable, even, and effective waterproof seal.

The goal of waxing is not merely to coat the leather, but to impregnate it. Pre-heating transforms the leather from a resistant surface into a receptive one, ensuring the wax is absorbed deep into the material for lasting protection.

The Science of Leather and Wax

To understand why pre-heating works, we need to look at the materials involved. Leather is a natural, porous material, and wax is a temperature-sensitive protectant.

Opening the Pores

Leather is composed of a dense matrix of protein fibers. Applying gentle warmth causes these fibers to relax and expand slightly, opening up the microscopic pores on the surface.

This turns the leather into something more like a sponge, ready to absorb the conditioning and waterproofing agents you are about to apply.

Lowering Wax Viscosity

Warming the boot's surface ensures that when the wax makes contact, it stays in a more liquid state for longer.

This lower viscosity allows the wax to flow easily and seep into the now-open pores and seams instead of hardening on the surface too quickly.

Deeper Penetration for Durability

The combination of open pores and liquid wax results in significantly deeper penetration.

This is the key to true weatherproofing. A surface-level coating can wear off quickly with flexing and abrasion, but wax that has been absorbed deep into the leather provides a much more resilient and long-lasting barrier against moisture.

Achieving a Uniform Finish

Applying wax to a cold boot can cause it to "clump" or solidify instantly, making it difficult to spread evenly.

A warm surface allows you to work the wax smoothly across the entire boot, preventing thick spots and ensuring a consistent, clean finish.

Understanding the Risks and Best Practices

While beneficial, applying heat to leather requires a measured approach. Excessive or improper heating can cause irreversible damage.

The Danger of Too Much Heat

The most critical thing to avoid is overheating the leather. High temperatures can cook the natural oils and fats within the hide, causing it to become dry, brittle, and prone to cracking.

Excessive heat can also melt the glues used in the boot's construction, potentially causing the sole to delaminate or other components to fail.

Choosing the Right Heat Source

Never use intense, direct heat. Avoid placing boots in an oven, near an open flame, or using a high-powered heat gun.

The safest methods involve gentle, indirect warmth. Good options include leaving them in a sunny spot for an hour, placing them near (not on) a radiator, or using a hairdryer on its lowest setting, held at a distance and kept constantly moving. The leather should feel warm to the touch, not hot.

Not a Substitute for a Clean Surface

Pre-heating should only be done after the boots have been thoroughly cleaned and are completely dry.

Heating a dirty boot will effectively bake the dirt and grime into the leather's pores, making them nearly impossible to remove later and hindering the wax's absorption.

Making the Right Choice for Your Goal

Applying this principle correctly is simple and depends on what you want to achieve.

- If your primary focus is maximum water resistance: Gentle pre-heating is essential, as it ensures the deepest possible wax penetration to fully seal seams and pores.

- If your primary focus is an efficient application: Even a few minutes of warmth will make the wax spread significantly faster and more evenly, saving you time and effort.

- If your primary focus is preserving the leather's lifespan: Always use low, indirect heat to get the benefits of absorption without the risk of drying out and damaging the leather.

Ultimately, treating the leather with gentle warmth before waxing is the defining step that separates a simple surface coating from true, deep-seated protection.

Summary Table:

| Benefit of Pre-Heating | Key Outcome |

|---|---|

| Opens Leather Pores | Allows for deep wax penetration, not just a surface coat. |

| Lowers Wax Viscosity | Wax flows easily into seams and pores for a complete seal. |

| Ensures Uniform Finish | Prevents clumping for a smooth, consistent application. |

| Increases Durability | Deeply impregnated wax resists wear from flexing and abrasion. |

Ready to produce high-performance boots that stand up to the elements?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise in materials like leather ensures the boots you source are built for superior protection and longevity. Let us help you create the reliable footwear your customers demand.

Contact our team today to discuss your manufacturing needs.

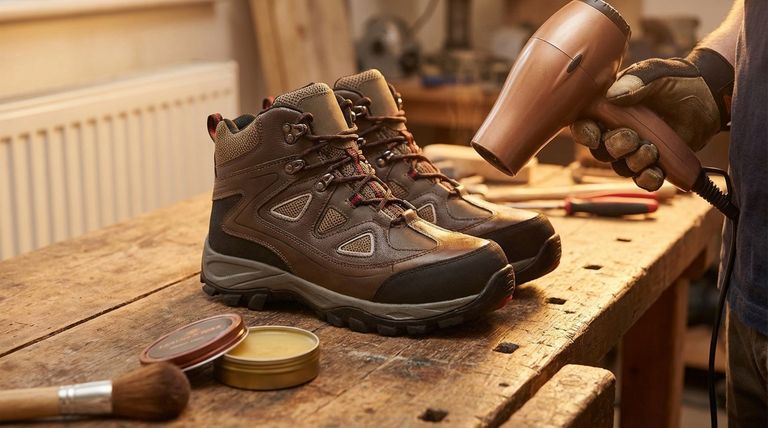

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the disadvantages of soft-toe boots? Understanding the Critical Safety Trade-Offs

- How does the sole design of Rigmaster boots improve traction? Master Diamond-Plate Surfaces

- What is the role of industrial footwear within the PPE framework of a palm oil refinery? Expert Safety Guide

- What should be monitored to maintain cowboy boots against wear and tear? A Proactive Inspection Guide

- How did Western work boots originate? From Cowboy Saddles to Modern Worksites

- What are the different types of PVC boots available? Choose the Right Boot for Your Job

- How should you prepare leather boots for cleaning and waterproofing? A Step-by-Step Guide to Long-Lasting Protection

- How can new work boots be broken in? A Step-by-Step Guide to a Pain-Free Fit