The primary disadvantage of soft-toe boots is their fundamental lack of protection against workplace hazards. Unlike their safety-toe counterparts, they offer no certified defense against crushing injuries from heavy falling objects or compression from machinery, and often provide minimal resistance to punctures from below. This makes them entirely unsuitable for any environment where impact risks are present.

Choosing a soft-toe boot is a deliberate trade-off. You gain significant advantages in weight, flexibility, and initial comfort, but you accept a higher risk profile by forgoing critical protection against crushing and puncture hazards.

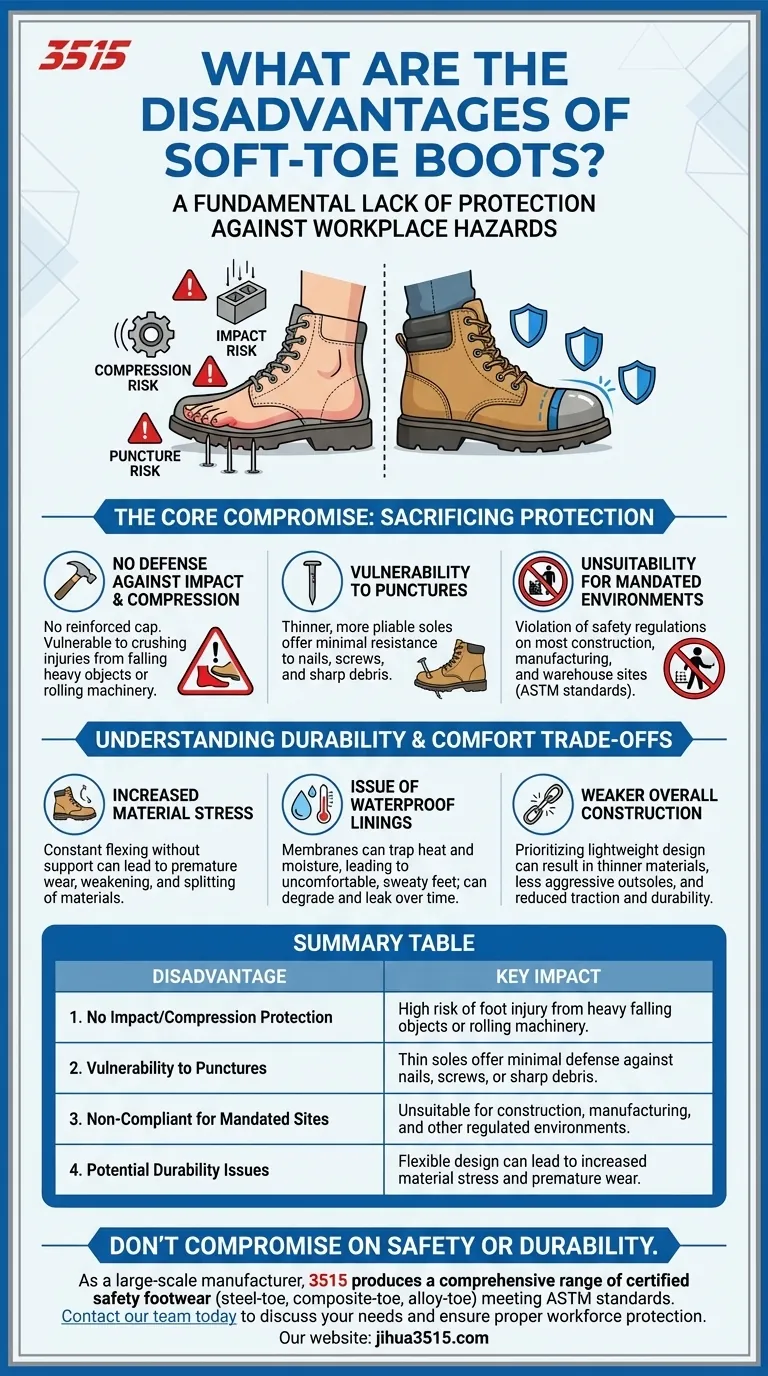

The Core Compromise: Sacrificing Protection

The most significant drawbacks of soft-toe boots are directly related to safety. They are not a substitute for safety-toe boots in any hazardous environment.

No Defense Against Impact and Compression

A soft-toe boot has no reinforced cap in the toe box. This means it offers virtually no protection if a heavy tool, piece of equipment, or building material is dropped on your foot.

They are equally vulnerable to compression injuries, such as those from a vehicle wheel or rolling machinery, where a safety toe is designed to prevent the toe box from collapsing.

Vulnerability to Punctures

Many boots designed for lightness and flexibility, including many soft-toe models, feature thinner and more pliable soles.

This construction can leave you vulnerable to sharp objects on the ground, such as nails, screws, or rebar, which can easily penetrate the sole and cause severe injury.

Unsuitability for Mandated Environments

Most professional construction sites, manufacturing plants, and warehouses have strict safety regulations that mandate footwear meeting specific ASTM standards for impact and compression.

Wearing a soft-toe boot in these environments is a compliance violation that can result in being removed from a job site and puts you at serious, unnecessary risk.

Understanding the Durability and Comfort Trade-offs

Beyond the critical safety issues, the design choices that define soft-toe boots can introduce other disadvantages related to their longevity and performance.

Increased Material Stress

The flexibility of a soft-toe boot, while comfortable, can lead to premature wear. The constant creasing and flexing of the material without a rigid toe structure to support it can cause leather or synthetic uppers to weaken and split over time.

The Issue of Waterproof Linings

Many boots, including soft-toe models, use waterproof membranes like Gore-Tex. While effective initially, these linings can trap heat and moisture, leading to sweaty, uncomfortable feet.

Over time and with heavy use, these membranes can also degrade or develop leaks, compromising their primary function and leaving you with damp feet.

Weaker Overall Construction

Often, boots that prioritize being lightweight and flexible—hallmarks of many soft-toe designs—make compromises in other areas. This can include using thinner materials and less aggressive outsoles, which may result in weaker traction on slippery or uneven terrain and reduced overall durability.

Making the Right Choice for Your Needs

Your decision should be based on a clear assessment of your daily environment and acceptable risk.

- If your primary focus is safety and compliance: A soft-toe boot is not an option; you must choose a certified steel-toe, composite-toe, or alloy-toe boot that meets your worksite's requirements.

- If your primary focus is flexibility and minimal weight for a low-risk job: Soft-toe boots are an excellent choice for roles in logistics, light assembly, or environments with no risk of falling objects or ground punctures.

- If your primary focus is outdoor recreation or daily wear: A soft-toe boot provides ample comfort and support, but carefully consider the terrain and potential for hazards before forgoing a more protective option.

Understanding these trade-offs empowers you to select footwear that truly serves your purpose, balancing comfort with necessary protection.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| No Impact/Compression Protection | High risk of foot injury from heavy falling objects or rolling machinery. |

| Vulnerability to Punctures | Thin soles offer minimal defense against nails, screws, or sharp debris. |

| Non-Compliant for Mandated Sites | Unsuitable for construction, manufacturing, and other regulated environments. |

| Potential Durability Issues | Flexible design can lead to increased material stress and premature wear. |

Don't compromise on safety or durability.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your team requires steel-toe, composite-toe, or alloy-toe boots that meet ASTM standards, we have the production capabilities and expertise to deliver.

Contact our team today to discuss your specific needs and ensure your workforce is properly protected.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the main materials used in the production of rain boots? A Guide to Durability & Comfort

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.

- What are the distinctive features of rain boots? Unmatched Waterproof Protection Explained

- What mechanical challenges arise for protective footwear in flood transitions? Ensure Stability in Dynamic Environments

- What factors should be considered when choosing rain boots? Find the Perfect Boot for Your Needs