Ultimately, traction in a work boot is about safety and stability. It is the single most important feature for preventing slips and falls in hazardous work environments, achieved primarily through a combination of a slip-resistant sole material and a purpose-built tread pattern designed for specific surfaces.

The critical insight is not simply that traction is important, but that the type of traction must be matched to your specific work environment. A sole designed for maximum grip on a flat concrete floor is fundamentally different from one designed for uneven, muddy terrain.

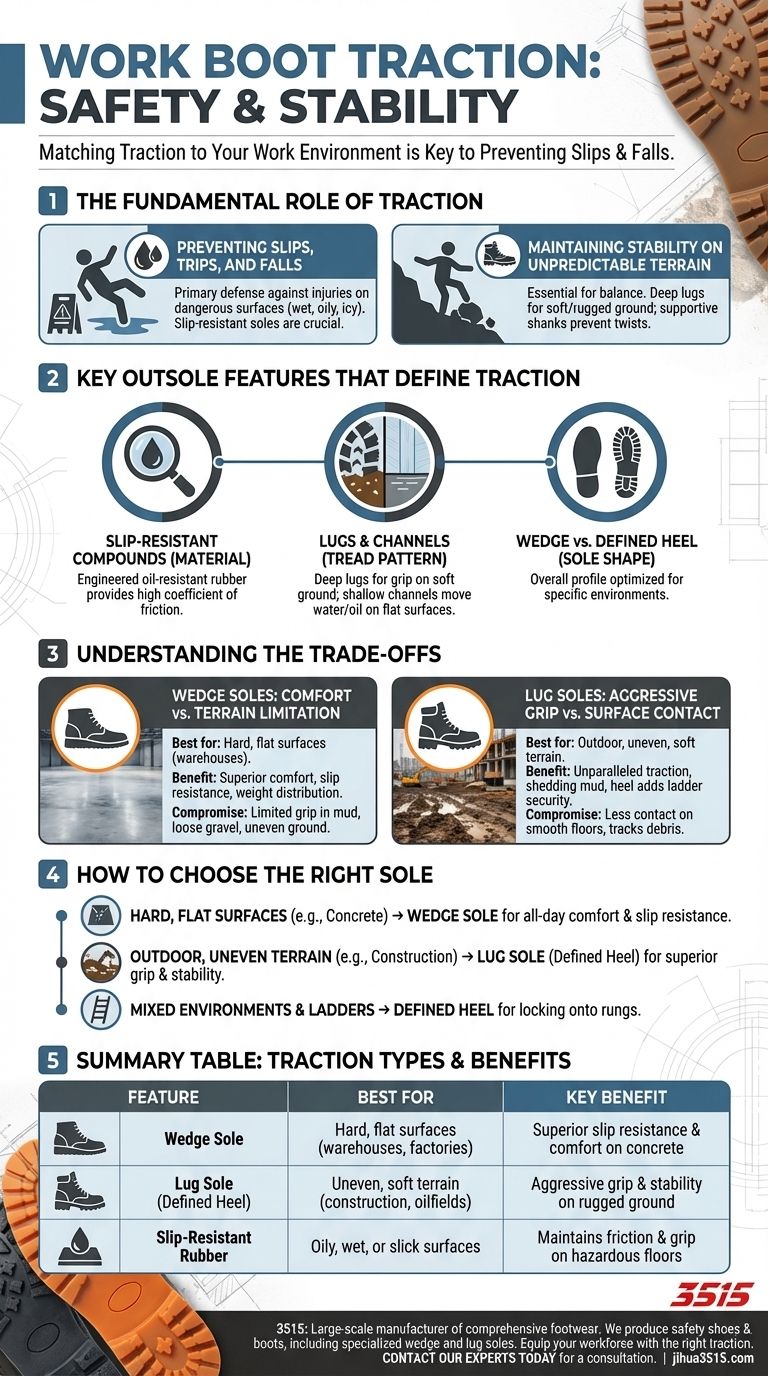

The Fundamental Role of Traction in Workplace Safety

Traction is your primary defense against workplace injuries caused by a loss of footing. It ensures you remain stable and in control, whether you're navigating a spill or crossing a construction site.

Preventing Slips, Trips, and Falls

The most immediate job of a high-traction outsole is to provide a firm grip on dangerous surfaces.

This includes wet floors, oil-slicked concrete, or icy patches, where a slip-resistant sole can be the difference between a normal workday and a serious accident.

Maintaining Stability on Unpredictable Terrain

For those working outdoors or on uneven ground, traction is essential for maintaining balance.

Specialized tread patterns and deep lugs bite into soft or rugged terrain, while features like higher ankle shafts and supportive shanks work with the sole to prevent twists and rolls.

Key Outsole Features That Define Traction

The level and type of traction a boot provides are determined by the design of its outsole. Understanding these components allows you to select the right tool for the job.

The Material: Slip-Resistant Compounds

The foundation of any good work boot sole is a specialized rubber compound.

These materials are engineered to be oil-resistant and provide a high coefficient of friction, ensuring they maintain their grip even on slick surfaces.

The Tread Pattern: Lugs and Channels

The pattern molded into the sole is what actively creates the grip.

Deep lugs are designed for soft or loose surfaces like mud, gravel, and dirt, digging in to provide stability. Shallow treads and channels are designed to move water and oil away from the sole's contact point on flat, hard surfaces.

The Sole Shape: Wedge vs. Defined Heel

The overall profile of the sole is optimized for specific environments. The two most common designs offer very different advantages.

A wedge sole is a flat-bottomed outsole made from a single piece of material. This design maximizes surface contact on flat, hard ground like concrete floors in warehouses or factories, providing excellent slip resistance and even weight distribution for comfort.

A defined heel or lug sole is what most people picture on a traditional work boot. The deep, aggressive tread pattern and separate heel block are built for superior grip on uneven, rugged, and soft terrain.

Understanding the Trade-offs

Choosing the right boot means understanding that no single design is perfect for every situation. Each sole type comes with inherent compromises.

Wedge Soles: Comfort vs. Terrain Limitation

Wedge soles are exceptionally comfortable for long days on your feet on hard, flat surfaces.

However, their shallow tread pattern offers limited grip in mud, on loose gravel, or on highly uneven ground. Their flat profile can also be less effective for climbing ladders.

Lug Soles: Aggressive Grip vs. Surface Contact

A deep lug sole provides unparalleled traction on outdoor sites, shedding mud and biting into soft earth. The defined heel adds security on ladders and steep grades.

Conversely, these soles make less direct contact with smooth, flat floors, which can slightly reduce their effectiveness in those specific settings. The deep lugs can also track debris indoors.

Beyond the Outsole: A System of Stability

Traction is part of a larger system. Internal components like steel or fiberglass shanks provide crucial midsole support, preventing the boot from flexing incorrectly and helping you maintain a stable footing on uneven objects.

How to Choose the Right Sole for Your Work

Evaluate your primary work environment to make a confident and safe choice.

- If your primary focus is working on hard, flat surfaces like concrete or asphalt: A wedge sole will provide the best combination of all-day comfort and reliable slip resistance.

- If your primary focus is working on outdoor, uneven, or soft terrain like construction sites or oilfields: A lug sole with a defined heel offers the superior grip and stability you need.

- If your primary focus is mixed environments that require climbing ladders: A defined heel is a critical safety feature for locking onto rungs.

Choosing the right outsole is a deliberate decision that directly impacts your daily safety and comfort.

Summary Table:

| Feature | Best For | Key Benefit |

|---|---|---|

| Wedge Sole | Hard, flat surfaces (e.g., warehouses, factories) | Superior slip resistance and comfort on concrete |

| Lug Sole (Defined Heel) | Uneven, soft terrain (e.g., construction sites, oilfields) | Aggressive grip and stability on rugged ground |

| Slip-Resistant Rubber | Oily, wet, or slick surfaces | Maintains friction and grip on hazardous floors |

Need work boots with the perfect traction for your team's safety?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including specialized wedge and lug soles engineered for maximum grip and durability in any environment.

We can help you equip your workforce with the right footwear to prevent slips and falls. Contact our experts today for a consultation on your specific needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What is a metatarsal guard in Wellington work boots? Essential Protection for High-Risk Jobs

- What is the significance of the approval label on NFPA-approved boots? Your Definitive Guide to Certified Safety

- How do the soles and midsoles of firefighter boots enhance safety? Ensure Foot Protection from the Ground Up

- Why is proper care and maintenance important for leather work boots? Extend Lifespan & Protect Your Investment

- Why are composite toe boots considered lightweight? The Science of Lighter Safety Footwear

- What are firefighter station boots used for? Essential Footwear for Daily Station Comfort & Professionalism

- Why is conditioning or oiling leather work boots important? Prevent Cracking & Extend Boot Life

- What factors should be considered when choosing between PVC, neoprene, and rubber work boots?