Choosing the right work boot material is a critical decision that directly impacts your daily safety and comfort. The best choice between PVC, neoprene, and rubber depends entirely on your specific work environment, the physical demands of your job, and your need for insulation. While all three materials are waterproof, they offer distinctly different advantages in flexibility, durability, and resistance to chemicals and temperature extremes.

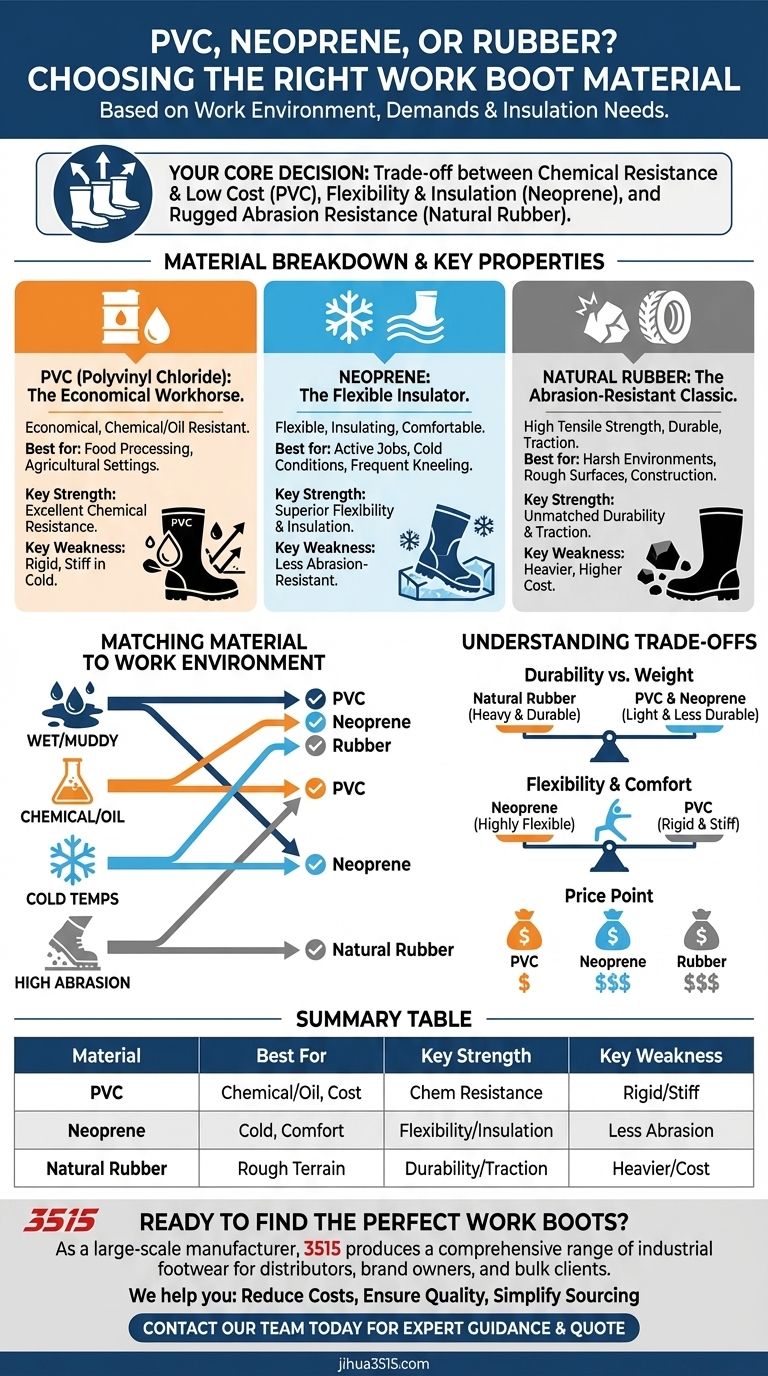

Your core decision is a trade-off between the chemical resistance and low cost of PVC, the superior flexibility and insulation of Neoprene, and the rugged, abrasion-resistant nature of natural Rubber. Understanding your primary daily hazard is the key to making the right choice.

A Breakdown of the Core Materials

To select the right boot, you first need to understand the fundamental properties of each material. They are not interchangeable, and each is engineered to solve a different set of problems.

PVC (Polyvinyl Chloride): The Economical Workhorse

PVC is a synthetic plastic polymer known for its excellent resistance to a wide range of substances. It is a cost-effective material often used in general-purpose work boots.

Its primary strength lies in its ability to stand up to chemicals, fats, and oils, making it a common choice in food processing and agricultural settings.

Neoprene: The Flexible Insulator

Neoprene is a synthetic rubber that offers a remarkable combination of flexibility and insulation. It remains pliable across a wide temperature range, preventing stiffness in the cold.

This material is exceptionally comfortable for active jobs that require frequent kneeling or squatting. Its insulating properties also provide warmth in cold conditions and keep feet comfortable in warmer weather.

Natural Rubber: The Abrasion-Resistant Classic

Sourced from plant sap, natural rubber is prized for its high tensile strength and superior resistance to cuts and abrasion. It is naturally waterproof, flexible, and provides excellent traction.

Rubber is the ideal choice for harsh environments with rough surfaces like gravel, rock, or unfinished concrete, where physical durability is the top priority.

Matching Material to Your Work Environment

The specific conditions you face every day are the most important factor. A boot that excels in one environment may be a liability in another.

For General Wet and Muddy Conditions

All three materials are 100% waterproof and will keep your feet dry in wet, muddy, or slushy environments. If basic waterproofing is your only concern, your choice will depend on other factors like comfort and price.

For Chemical and Oil Exposure

PVC is often the superior choice here. Its polymer structure is highly resistant to degradation from agricultural chemicals, grease, and processing fluids, ensuring both safety and a longer lifespan for the boot.

For Cold Temperatures

Neoprene is the clear winner for insulation. Its cellular structure traps air, providing a thermal barrier that keeps feet warm. While insulated rubber is also an option, standard PVC becomes very stiff and can even crack in extreme cold.

For High-Abrasion Surfaces

Natural rubber excels where boots are subjected to constant scraping and physical abuse. Its resilience against cuts and punctures makes it the most durable option for construction, mining, or forestry work.

Understanding the Trade-offs

No single material is perfect. Choosing one means prioritizing its strengths over the potential weaknesses you can tolerate.

The Durability vs. Weight Dilemma

Natural rubber is typically the most durable against physical damage but is also the heaviest material. This added weight can contribute to fatigue over a long shift.

PVC and neoprene boots are significantly lighter, which enhances comfort. However, they may not withstand the same level of intense physical abuse as a high-quality rubber boot.

Flexibility and Long-Term Comfort

Neoprene's exceptional flexibility is a major advantage for jobs requiring a wide range of motion. This prevents the boot from fighting your natural movements.

While high-grade rubber is also flexible, PVC is the most rigid of the three. This can lead to discomfort and chafing during physically active work, especially in colder temperatures.

The Price Point Factor

PVC boots are generally the most affordable option, making them an excellent choice for basic protection or infrequent use.

Neoprene and premium rubber boots represent a higher initial investment. This cost is justified by their specialized performance features, enhanced comfort, and often longer lifespan under specific conditions.

Making the Right Choice for Your Job

Filter your decision through the lens of your most common and critical task.

- If your primary focus is cost-effectiveness and chemical resistance: Choose PVC for its affordability and resilience against oils, fats, and many industrial chemicals.

- If your primary focus is all-day comfort and insulation in varied temperatures: Choose Neoprene for its superior flexibility, lightweight feel, and excellent thermal properties.

- If your primary focus is rugged durability and slip resistance on rough terrain: Choose high-quality natural Rubber for its unmatched resistance to abrasion and excellent traction.

Selecting the right material is a fundamental investment in your daily safety, comfort, and productivity.

Summary Table:

| Material | Best For | Key Strength | Key Weakness |

|---|---|---|---|

| PVC | Chemical/Oil Exposure, Cost-Effectiveness | Excellent chemical resistance, Low cost | Rigid, Stiff in cold |

| Neoprene | Cold Temperatures, All-Day Comfort | Superior flexibility & insulation, Lightweight | Less abrasion-resistant |

| Natural Rubber | Rough Terrain, High-Abrasion Surfaces | Unmatched durability & traction, Flexible | Heavier, Higher cost |

Ready to find the perfect work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of PVC, neoprene, and rubber boots, ensuring you get the right combination of safety, comfort, and durability for your specific work environment.

We help you:

- Reduce Costs: Benefit from our economies of scale and competitive pricing.

- Ensure Quality: Rely on our rigorous manufacturing standards for long-lasting performance.

- Simplify Sourcing: Get a one-stop solution for all your industrial footwear needs.

Let's discuss your requirements. Contact our team today for expert guidance and a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the steps to waterproof leather boots effectively? A 5-Step Guide to Lasting Protection

- Why are high-durability work boots essential for stone cutting? Protect Operators from High-Velocity Shards

- What are the key features to look for in winter biking boots? Essential Guide for Warm, Dry Feet

- What historical factors affected engineer boot production? From WWII Workwear to Rebel Icon

- What are the steps for maintaining and storing lace-up boots? A Guide to Extend Their Lifespan

- When is it appropriate to use leather conditioner on boots? Identify the Signs of Dry Leather

- Why is proper fit important in work boots? Ensure Safety, Comfort & Long-Term Health

- How long can Goodyear-welted shoes last if rotated? A Guide to Decades of Wear