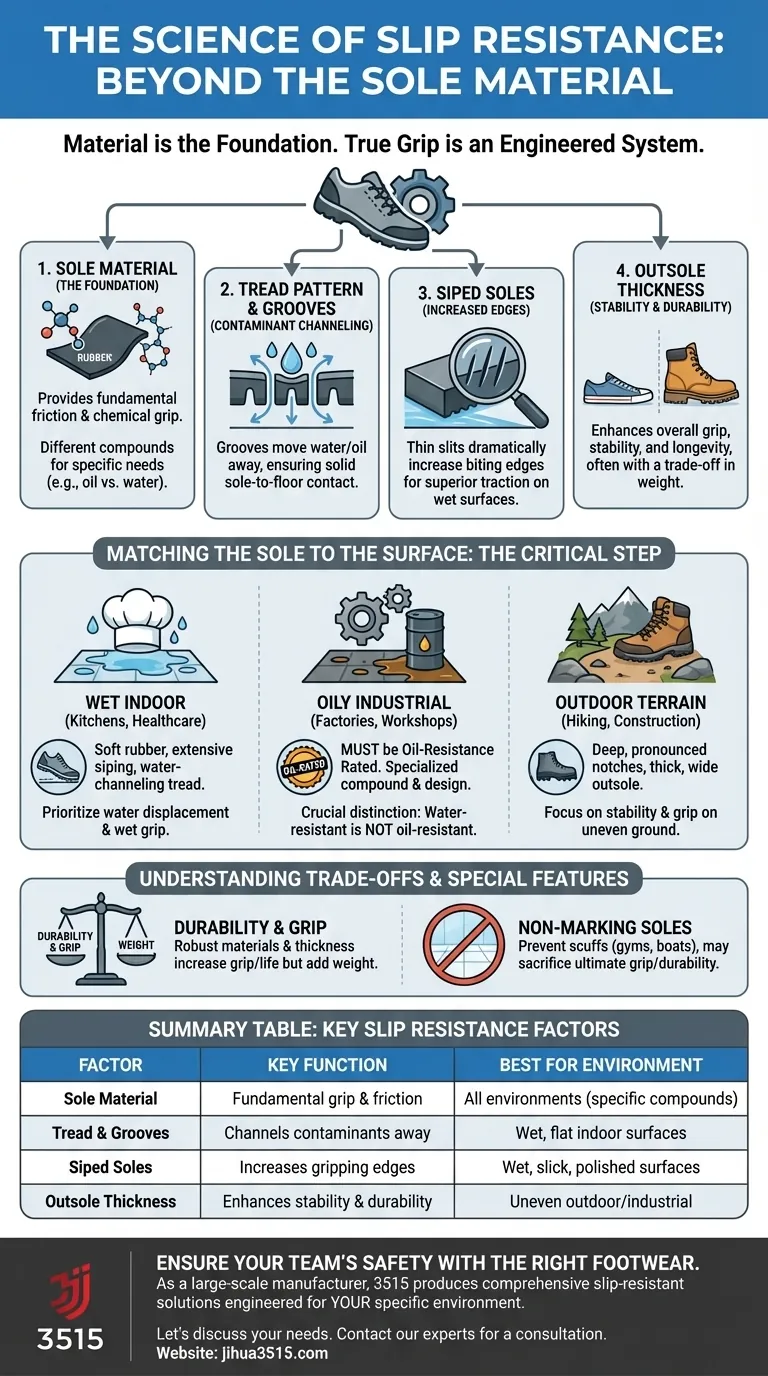

The sole material of a shoe is the foundation of its slip resistance. This material directly determines the shoe's inherent grip and its performance against different walking surfaces, especially when contaminants like water or oil are introduced.

While the sole's material provides the fundamental chemical grip, true slip resistance is an engineered system. The design of the tread, the thickness of the outsole, and the specific surface you walk on are equally critical factors.

Why Material is Only the Starting Point

A shoe's ability to prevent a slip is far more complex than just the type of rubber used. The material is the first step, but its effectiveness depends entirely on how it's engineered and applied.

The Role of Rubber Compounds

Virtually all slip-resistant shoes use a rubber outsole. Rubber provides an excellent coefficient of friction, which is the scientific measure of grip. However, different rubber compounds are formulated for specific conditions.

The Myth of the "Rubber Sole Guarantee"

Simply having a rubber sole does not make a shoe slip-resistant. A standard fashion sneaker and a high-performance work boot may both have rubber soles, but their safety profiles are vastly different. The engineering of the sole is what creates true resistance.

The Critical Elements Beyond Material

True slip resistance comes from a combination of design features that work together. The material provides potential, but the design unlocks its performance.

Tread Pattern and Grooves

The grooves and channels in an outsole, known as the tread, are designed to move contaminants away from the point of contact. Deep, well-spaced grooves effectively channel water or oil, allowing the sole's material to make solid contact with the floor.

The Function of Siped Soles

Siping refers to very thin slits cut into the sole's tread blocks. This technique dramatically increases the number of sharp, gripping edges on the sole, providing superior traction on wet or slick surfaces by creating pathways for water to escape.

The Importance of Outsole Thickness

Anti-slip shoes often feature thicker outsoles. This additional thickness not only contributes to the shoe's durability but also enhances overall grip and stability, providing a more secure platform on slippery ground.

Matching the Sole to the Surface

The single most important factor in choosing a shoe is understanding the environment where it will be used. A sole designed for one hazard may be ineffective against another.

Why Your Environment Dictates Your Shoe

Different floor types and contaminants require specific sole designs. A shoe that performs exceptionally well on a wet kitchen tile may offer poor grip on an oily industrial concrete floor.

Water vs. Oil: A Critical Distinction

It is crucial to understand that water-resistance and oil-resistance are not the same. Oil is more viscous and harder for a tread pattern to channel away. Always check a shoe's specifications to ensure it is rated for the specific hazards of your workplace.

Indoor vs. Outdoor Considerations

The demands of indoor and outdoor surfaces differ significantly. A kitchen shoe needs shallow treads and siping for flat, wet floors. In contrast, a hiking boot needs deep, pronounced notches and a wider sole to grip uneven and loose terrain like mud or wet rocks.

Understanding the Trade-offs

Choosing the right shoe often involves balancing competing features. Maximizing one attribute, like durability, can sometimes impact another, like weight.

Durability vs. Weight

The robust materials and thicker outsoles that contribute to a shoe's durability and slip resistance also make it heavier. This is a necessary trade-off for performance and longevity in demanding environments.

Non-Marking Soles

In some environments, such as gyms or boat decks, preventing scuff marks is a priority. Non-marking soles are made from specific compounds that do not leave black marks, though this may involve a trade-off in ultimate grip or durability compared to specialized work soles.

How to Choose the Right Slip-Resistant Shoe

Your choice should be guided by your primary environment and the specific hazards you face.

- If your primary focus is a wet indoor workplace (kitchen, healthcare): Look for soft rubber outsoles with extensive siping and tread patterns designed to channel water.

- If your primary focus is an oily industrial environment: You must verify the shoe is specifically rated for "oil-resistance," as standard water-resistant designs may not suffice.

- If your primary focus is outdoor terrain (hiking, trails): Prioritize shoes with deep, pronounced notches and a thick, wide outsole for maximum stability and grip on uneven ground.

Understanding that slip resistance is a complete system—not just a single material—is the key to ensuring your safety and stability on any surface.

Summary Table:

| Slip Resistance Factor | Key Function | Best For Environment |

|---|---|---|

| Sole Material (Rubber Compound) | Provides the fundamental chemical grip and friction. | All environments; specific compounds for oil or water. |

| Tread Pattern & Grooves | Channels water/oil away from the sole's contact point. | Wet, flat indoor surfaces (e.g., kitchens). |

| Siped Soles | Increases gripping edges for superior traction on slick surfaces. | Wet floors, light oil, or polished surfaces. |

| Outsole Thickness | Enhances stability, durability, and overall grip. | Uneven outdoor terrain or demanding industrial settings. |

Ensure Your Team's Safety with the Right Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the precise rubber compounds and tread designs your specific environment demands.

We help you mitigate workplace risks by providing durable, high-performance footwear that combines the right material with the optimal design for ultimate slip resistance.

Let's discuss your specific needs and create a safer working environment together. Contact our experts today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.