At their core, composite-toe boots are engineered to provide critical workplace safety by protecting your feet from impact and compression injuries. They achieve this using strong, non-metallic materials like carbon fiber, fiberglass, or plastic, making them a modern alternative to traditional steel-toe caps.

The essential function of composite-toe boots is to offer robust protection against crushing and falling objects while also providing superior electrical hazard resistance and thermal insulation compared to their steel counterparts.

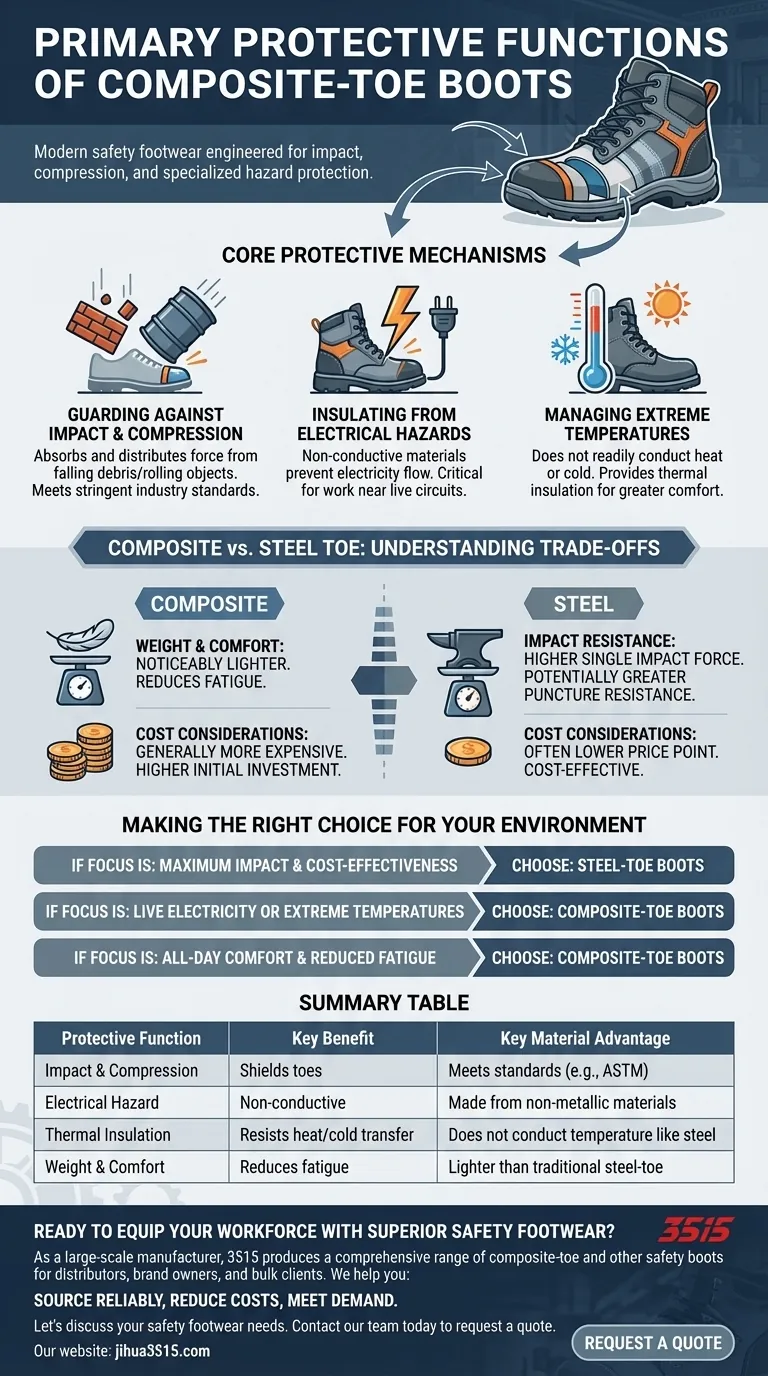

Core Protective Mechanisms Explained

To understand their value, it's important to break down the specific types of protection composite-toe boots offer and how their material composition makes that possible.

Guarding Against Impact and Compression

The primary function is to shield your toes from injury. The built-in composite cap is designed to absorb and distribute the force from falling debris or rolling objects.

These boots meet or exceed stringent industry safety standards for impact and compression, making them essential equipment in high-risk environments like construction sites and industrial manufacturing facilities.

Insulating from Electrical Hazards

Because they are made from non-metallic materials, composite-toe boots do not conduct electricity.

This feature provides a critical layer of protection for anyone working in environments where they might be exposed to live electrical circuits or static electricity buildup.

Managing Extreme Temperatures

Unlike steel, composite materials do not readily conduct heat or cold.

This thermal insulation provides greater comfort and safety for individuals working in extremely hot or cold conditions, preventing the toe cap from becoming dangerously uncomfortable.

Understanding the Trade-offs: Composite vs. Steel Toe

While composite-toe boots offer distinct advantages, they exist on a spectrum of safety footwear. The choice between composite and steel often comes down to balancing specific workplace hazards against factors like weight and cost.

Impact Resistance

Both steel and composite-toe boots are rated to protect against a specific level of impact. However, steel can often withstand a higher single impact force before fracturing.

Composite caps are incredibly strong but may not offer the same absolute level of puncture or crush resistance as the toughest steel caps in extreme scenarios.

Weight and Comfort

This is a significant advantage for composite materials. Composite-toe boots are noticeably lighter than their steel-toe equivalents.

This reduction in weight can lead to less fatigue and greater comfort over the course of a long workday, which is a critical factor for many workers.

Cost Considerations

The advanced materials and manufacturing processes used for composite-toe boots generally make them more expensive than traditional steel-toe boots.

The added benefits of lower weight and electrical hazard protection often justify the higher initial investment for specific roles and environments.

Making the Right Choice for Your Environment

Selecting the proper safety boot requires a clear understanding of your primary workplace risks.

- If your primary focus is maximum impact protection and cost-effectiveness: Steel-toe boots often provide the highest level of resistance to crushing force at a lower price point.

- If your primary focus is working around live electricity or in extreme temperatures: The non-conductive properties of composite-toe boots make them the essential choice.

- If your primary focus is all-day comfort and reduced fatigue: The lighter weight of composite-toe boots offers a significant advantage for long shifts with extensive walking or movement.

Ultimately, understanding these key differences empowers you to select the safety footwear that truly matches your specific workplace hazards and needs.

Summary Table:

| Protective Function | Key Benefit | Key Material Advantage |

|---|---|---|

| Impact & Compression | Shields toes from falling/rolling objects | Meets safety standards (e.g., ASTM) |

| Electrical Hazard | Non-conductive for live electrical work | Made from non-metallic materials |

| Thermal Insulation | Resists heat/cold transfer for comfort | Does not conduct temperature like steel |

| Weight & Comfort | Reduces fatigue during long shifts | Lighter than traditional steel-toe boots |

Ready to Equip Your Workforce with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite-toe and other safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring you get durable, compliant, and comfortable boots tailored to your specific industry hazards.

We help you:

- Source Reliably: Ensure a steady supply of high-quality safety boots.

- Reduce Costs: Benefit from our large-scale manufacturing efficiencies.

- Meet Demand: Get the right mix of composite-toe and other safety footwear for your market.

Let's discuss your safety footwear needs. Contact our team today to request a quote or learn more about our manufacturing capabilities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium KPU Injection Athletic Style Safety Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear