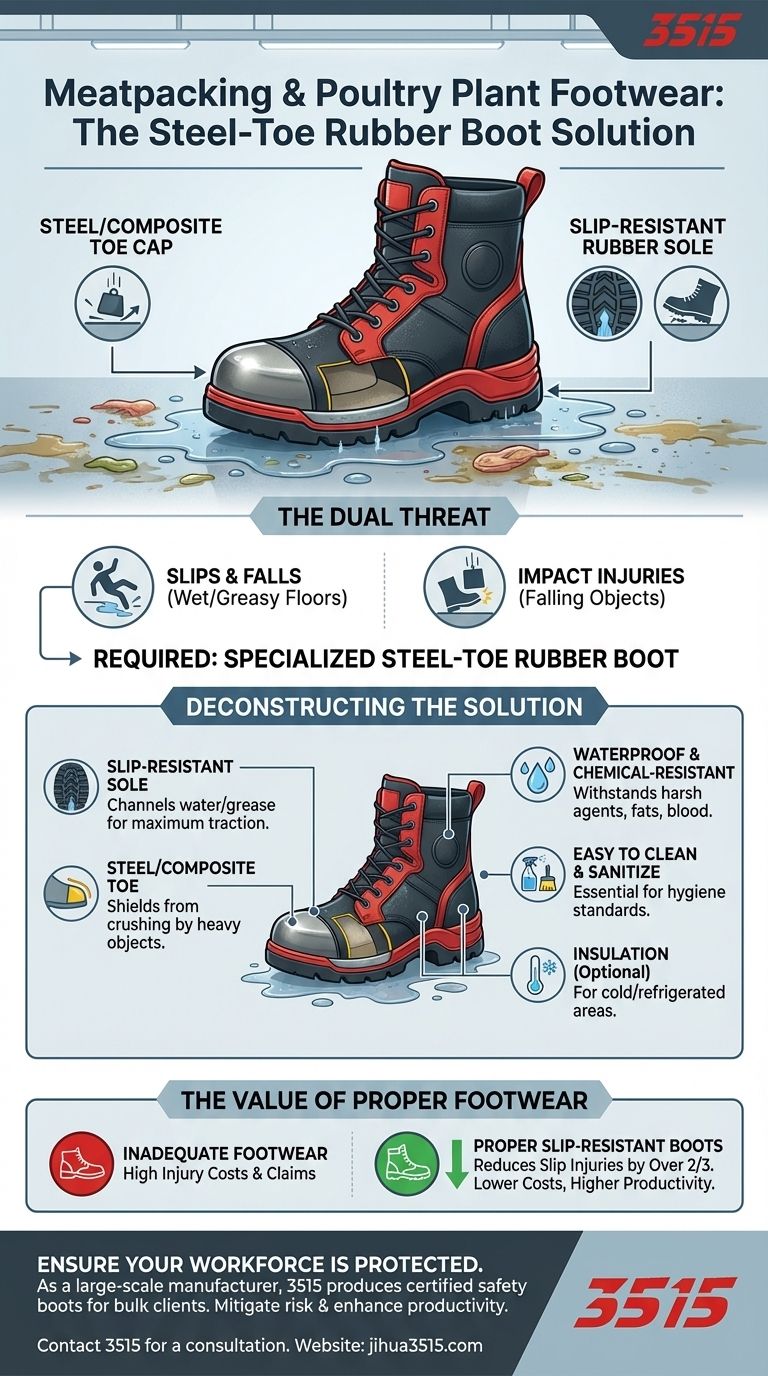

In meatpacking and poultry processing plants, the required footwear is a specialized type of steel-toe rubber boot. This specific mandate is a direct response to the industry's severe and persistent workplace hazards, primarily extremely slippery floors and the risk of impact injuries.

The core principle is not simply about wearing boots, but about using footwear engineered to simultaneously combat two distinct threats: catastrophic slips from wet and greasy surfaces, and crushing injuries from heavy falling objects.

Why This Specific Footwear is Non-Negotiable

Understanding the environment of a meat or poultry processing plant clarifies why standard work boots are insufficient. The combination of water, animal fats, blood, and potent cleaning agents creates a uniquely hazardous floor surface that demands a specialized solution.

The Dual Threat: Slips and Impacts

The primary risk is slipping on floors that are constantly wet and often contaminated with slick organic matter. These conditions can cause severe falls, leading to significant injuries.

Simultaneously, workers are exposed to impact and compression hazards from heavy machinery, falling tools, or animal carcasses. This necessitates protection for the foot itself.

Deconstructing the "Steel-Toe Rubber Boot"

The two key features of this footwear directly address the dual threats.

Rubber construction is essential because it is waterproof, durable, and easy to clean and sanitize, which is critical in a food processing environment. The material and tread are also designed to provide superior grip on wet surfaces.

A steel toe cap (or a modern composite equivalent) is a non-negotiable safety feature that shields the toes from being crushed by heavy falling or rolling objects.

The Science of Slip Resistance

Effective slip-resistant footwear is the first line of defense against falls. The outsoles of these boots feature specialized tread patterns designed to channel liquids away from the point of contact, maximizing the sole's surface area on the floor. This greatly improves traction and stability in hazardous conditions.

Beyond the Mandate: Critical Considerations

While "steel-toe rubber boot" is the rule, not all boots that fit this description offer the same level of protection or durability. Selecting the right equipment requires a deeper look at the specific challenges of the plant.

Chemical and Organic Resistance

The boot's material must be able to withstand constant exposure to animal fats, byproducts, and harsh industrial cleaning chemicals. A standard rubber boot may degrade quickly, compromising both its structural integrity and its slip-resistant properties.

Temperature and Insulation

Many processing plants operate in refrigerated environments. In these cases, insulated boots are necessary to prevent cold-related foot injuries and ensure worker comfort and focus over a long shift.

The High Cost of Inadequate Footwear

Failing to provide or require appropriate footwear has direct consequences. As research shows, providing proper slip-resistant shoes can reduce slip-related injuries by over two-thirds, dramatically lowering workers' compensation claims and lost work time.

Making the Right Choice for Your Goal

Selecting protective footwear is a critical risk management decision. Your choice must be based on a clear-eyed assessment of the specific hazards present in the work environment.

- If your primary focus is compliance in a meat or poultry plant: Mandate waterproof, chemical-resistant, steel-toe rubber boots with a certified high-traction, slip-resistant sole.

- If your primary focus is safety in a general manufacturing or warehouse setting: Assess the main hazard. If it's spilled oil or water, prioritize certified slip-resistant footwear; if it's falling objects, prioritize footwear with safety toes.

Ultimately, investing in the correct, high-quality footwear is a direct investment in the safety and productivity of your workforce.

Summary Table:

| Feature | Why It's Required for Meat/Poultry Plants |

|---|---|

| Slip-Resistant Rubber Sole | Channels water/grease away to prevent falls on wet, slippery floors. |

| Steel/Composite Toe Cap | Protects feet from heavy falling objects like tools or animal carcasses. |

| Waterproof & Chemical-Resistant | Withstands constant exposure to water, fats, blood, and cleaning agents. |

| Easy to Clean & Sanitize | Essential for maintaining hygiene standards in food processing environments. |

| Insulation (Optional) | Provides warmth and comfort for workers in refrigerated processing areas. |

Ensure your workforce is protected with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and rubber boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial footwear, including the specialized waterproof, steel-toe, and slip-resistant boots required for meatpacking and poultry plants. We help you mitigate risk, reduce workplace injuries, and enhance productivity. Contact 3515 today for a consultation on your protective footwear needs.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How should the outside of work boots be cleaned? A Simple Guide to Extend Their Lifespan

- What are the benefits of shock-absorbing soles? Reduce Joint Strain and Fatigue

- How has the cultural significance of cowboy boots persisted? From Workwear to Fashion Icon

- How are waterproof boots tested? The Rigorous Lab Process Explained

- What features should work boots have for cold or hot working conditions? A Guide to Temperature-Specific Safety

- What are the key indicators of a properly fitting work boot? Ensure All-Day Comfort and Safety

- Which material offers the best chemical protection in work boots? PVC is the definitive choice for hazardous liquids.

- How should composite toe boots be cared for to ensure longevity? Extend Boot Life with Simple Steps