On any construction site, safety is a system, and the foundation of that system is protective footwear. Construction workers require steel-toe boots because their environment is inherently filled with hazards that can cause severe foot injuries. These boots provide a critical shield against the impact of falling tools, the compression from heavy materials or equipment, and other dangers unique to the trade.

The need for steel-toe boots is not just a rule; it's a direct response to the specific, high-risk hazards of a construction environment. While the reinforced toe is the most famous feature, it is part of a larger system of protection that must be matched to the precise dangers of the job at hand.

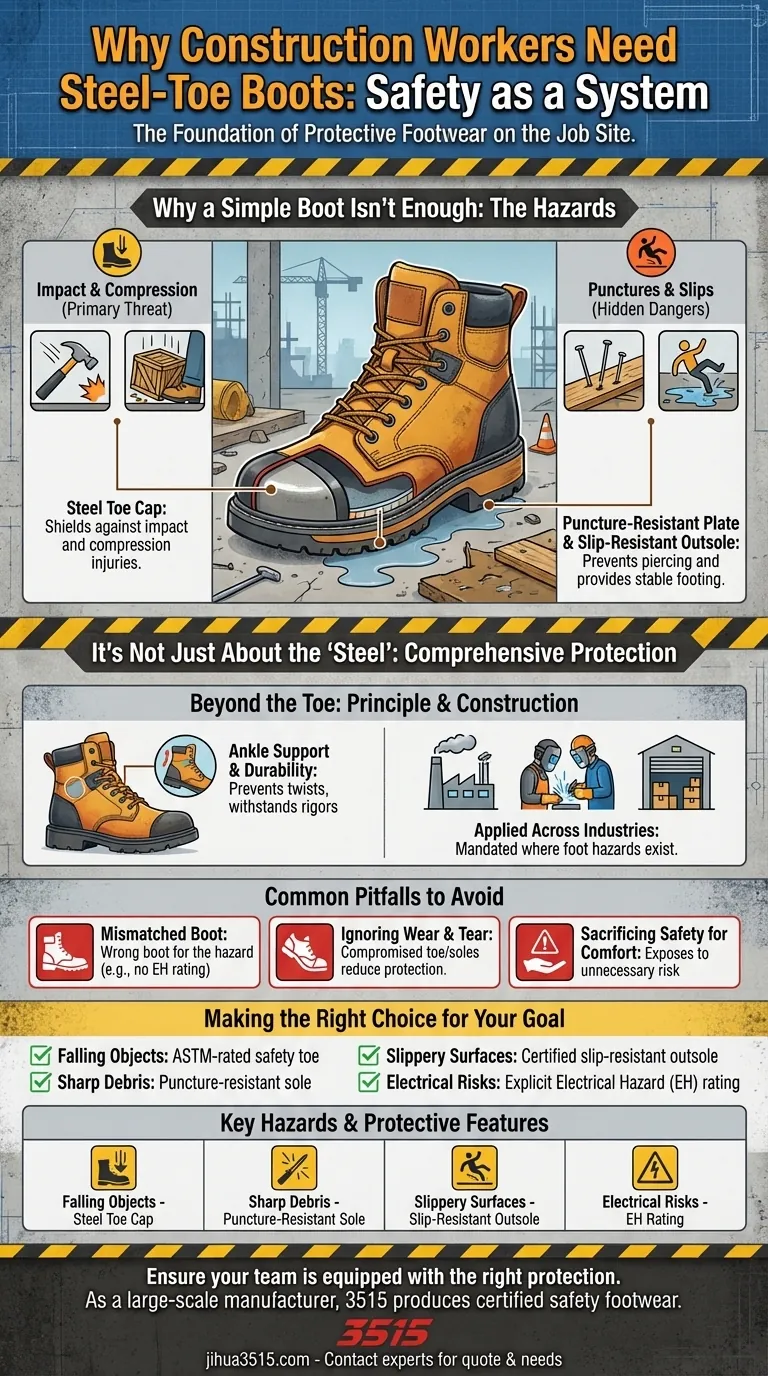

Why a Simple Boot Isn't Enough: The Hazards of a Job Site

A construction site is a dynamic environment where the risks change daily. Standard footwear offers virtually no protection against the common physical threats present in this line of work.

The Primary Threat: Impact and Compression

The most obvious danger comes from above and around. A steel toe cap is engineered to protect the foot from the force of heavy falling objects, such as a dropped hammer or a piece of lumber.

It also protects against compression, which can occur if a foot is caught under a heavy rolling object or pinned by shifting materials. This reinforced toe is the first line of defense against crushing injuries.

The Hidden Dangers: Punctures and Slips

The ground on a construction site is often littered with sharp objects like loose nails, screws, and rebar. Many safety boots include a puncture-resistant plate in the sole to prevent these items from piercing the foot from below.

Furthermore, surfaces can be uneven, wet, or oily. Boots designed for construction feature slip-resistant outsoles with deep treads to provide stable footing and prevent falls.

It's Not Just About the "Steel"

The term "steel-toe boot" is often used as a catch-all, but the principle of safety footwear extends to many industries and materials. The specific hazard dictates the type of protection needed.

A Principle Applied Across Industries

The requirement for safety footwear is not exclusive to construction. Any industry where workers face similar foot hazards mandates their use.

This includes manufacturing, welding, auto repair, landscaping, and warehouse operations. In each case, the footwear is chosen to mitigate the specific risks of that environment.

The Importance of Overall Boot Construction

While the reinforced toe is crucial, the rest of the boot is equally important for safety and durability.

A well-made work boot offers ankle support to prevent twists on uneven ground, uses durable materials to withstand daily rigors, and is constructed to provide support over long hours of standing and walking.

Common Pitfalls to Avoid

Choosing the wrong boot or using it improperly can create a false sense of security. True safety comes from making an informed choice based on a clear understanding of your work environment.

Mismatching the Boot to the Hazard

The most common mistake is assuming any steel-toe boot is sufficient for any job. A boot without a puncture-resistant sole is inadequate on a demolition site, just as one without an Electrical Hazard (EH) rating is dangerous for an electrician.

Ignoring Wear and Tear

Protective footwear is not permanent. A boot that has sustained a significant impact may have a compromised toe cap, even if the damage isn't visible. Worn-out soles lose their slip resistance, and cracks in the material can compromise overall protection.

Sacrificing Safety for Comfort

While modern safety boots are more comfortable than ever, their primary purpose is protection. Opting for lighter, less protective footwear to improve comfort can expose you to unnecessary risk.

Making the Right Choice for Your Goal

Your choice of footwear should be a direct reflection of the tasks you perform every day. Analyze your environment and select a boot with features that directly counter those risks.

- If your primary focus is protection from falling objects: Ensure your boots have an ASTM-rated safety toe for impact and compression.

- If your primary focus is working around sharp debris: Your boots must have a designated puncture-resistant plate in the sole.

- If your primary focus is navigating slippery or uneven surfaces: Prioritize a boot with a certified, high-traction, slip-resistant outsole.

- If your primary focus is working near live electrical circuits: You must select boots that carry an explicit Electrical Hazard (EH) rating.

Ultimately, the right boot is not just a piece of equipment; it is a critical tool that enables you to perform your job safely and effectively.

Summary Table:

| Key Hazard | Protective Feature | Why It Matters |

|---|---|---|

| Falling Objects | Steel Toe Cap | Shields feet from impact and compression injuries. |

| Sharp Debris | Puncture-Resistant Sole | Prevents nails or sharp objects from piercing the foot. |

| Slippery Surfaces | Slip-Resistant Outsole | Provides stable footing to prevent slips and falls. |

| Electrical Risks | EH (Electrical Hazard) Rating | Offers protection against live circuits (if applicable). |

Ensure your team is equipped with the right protection. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of steel-toe boots and work shoes, designed to meet the specific hazards of your industry. Get durable, reliable footwear that meets safety standards—contact our experts today for a quote or to discuss your needs!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What is the purpose of steel toe caps in firefighter boots? Maximum Impact & Crush Protection

- What are the benefits of steel-toe boots in terms of impact resistance? Get Maximum Protection for Your Workforce

- How do steel toe boots contribute to comfort and security? Balancing Safety with All-Day Wearability

- How has the perception of steel toe boots being bulky and heavy changed? Discover Lightweight Safety Footwear

- Do moc toe boots have steel toe? Get Durable, Safety-Compliant Footwear

- What are the characteristics of steel safety toes? A Guide to Maximum Impact Protection

- How does a reinforced safe toe tip contribute to footwear? Enhancing Safety and Structural Durability

- Which occupations typically require steel toe boots? A Guide to Essential Foot Protection