At their core, steel safety toes are the traditional standard for heavy-duty footwear protection. They are characterized by their exceptional strength and resistance to impact, but this durability comes with notable trade-offs in weight and conductivity.

The defining feature of a steel safety toe is its uncompromising strength. While it offers superior protection against impact and compression, its weight and its ability to conduct heat and electricity are critical factors that determine its suitability for a specific job.

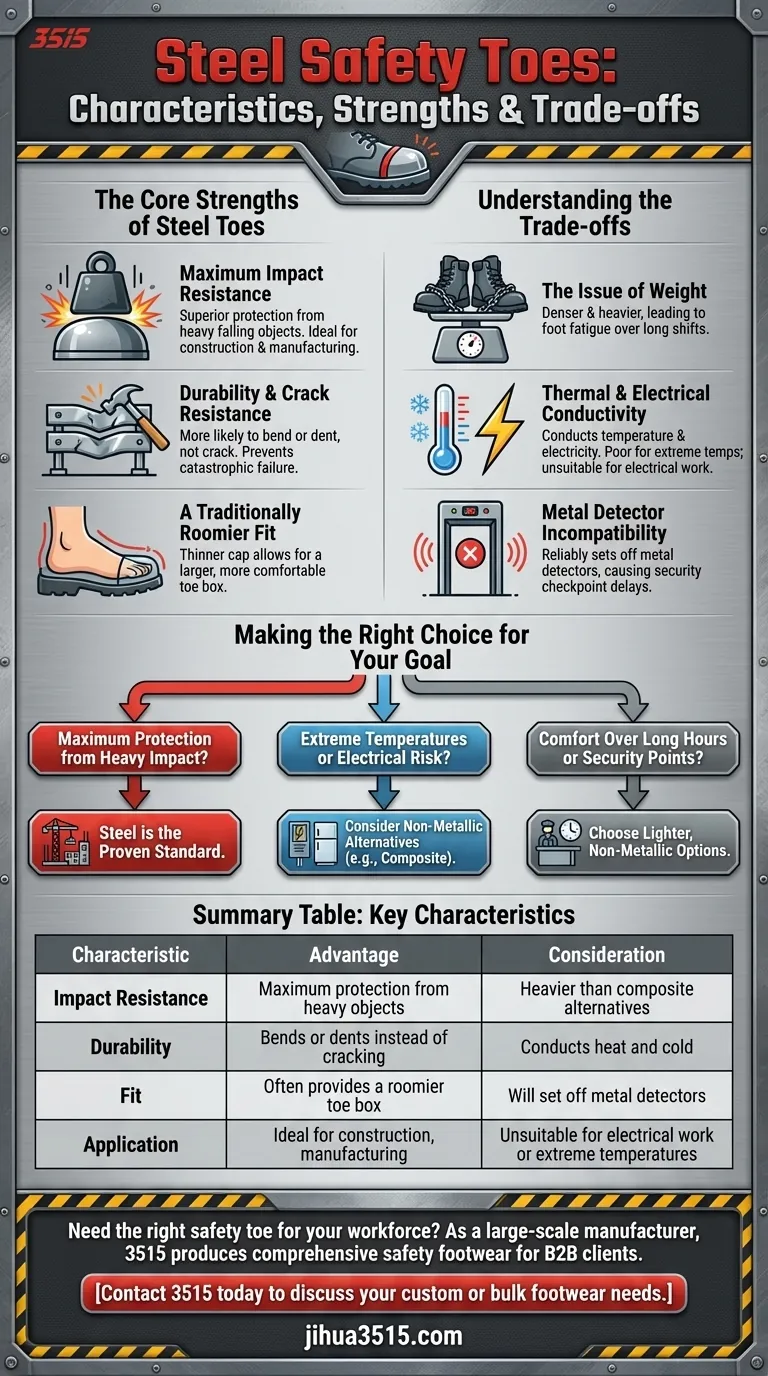

The Core Strengths of Steel Toes

Steel became the industry standard for a reason. Its fundamental properties provide a level of protection that has been trusted for decades in the most demanding work environments.

Maximum Impact Resistance

The primary characteristic of steel is its ability to withstand serious impact and compression. Steel toes are designed to protect the wearer from heavy falling objects, making them ideal for construction, manufacturing, and warehouse work.

Durability and Crack Resistance

Unlike some materials that can crack or shatter under extreme force, steel is more likely to bend or dent. This behavior ensures the protective barrier remains intact even after a significant impact, preventing catastrophic failure.

A Traditionally Roomier Fit

Steel's strength allows for a protective cap that can sometimes be thinner than other materials. This can result in a larger, more spacious toe box, which may provide more comfort and room for your toes.

Understanding the Trade-offs

While exceptionally strong, the inherent properties of steel introduce practical limitations that are crucial to consider before making a choice.

The Issue of Weight

Steel is denser and heavier than modern alternatives like composite materials. Over the course of a long shift, this added weight can contribute to foot fatigue and overall physical strain.

Thermal and Electrical Conductivity

As a metal, steel readily conducts temperature and electricity. This makes steel toe boots a poor choice for work in extreme cold or heat and entirely unsuitable for electricians or anyone working near live circuits.

Metal Detector Incompatibility

The presence of steel will reliably set off metal detectors. This is a significant inconvenience for individuals working in secure facilities, such as airports, government buildings, or power plants, who must pass through security checkpoints regularly.

Making the Right Choice for Your Goal

Selecting the right safety toe is about matching the material's characteristics to the specific hazards of your environment.

- If your primary focus is maximum protection from heavy impact: Steel is the proven, traditional standard for construction or industrial sites with significant drop hazards.

- If you work in environments with extreme temperatures or electrical risk: You must consider non-metallic alternatives like composite toes for your safety.

- If comfort over long hours is a priority or you pass through metal detectors: A lighter, non-metallic safety toe will provide protection with fewer daily drawbacks.

Understanding these fundamental characteristics ensures you select safety footwear that truly protects you without introducing unnecessary risk or discomfort.

Summary Table:

| Characteristic | Advantage | Consideration |

|---|---|---|

| Impact Resistance | Maximum protection from heavy objects | Heavier than composite alternatives |

| Durability | Bends or dents instead of cracking | Conducts heat and cold |

| Fit | Often provides a roomier toe box | Will set off metal detectors |

| Application | Ideal for construction, manufacturing | Unsuitable for electrical work or extreme temperatures |

Need the right safety toe for your workforce? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with steel, composite, and alloy toes for distributors, brand owners, and bulk clients. We ensure your team has the perfect balance of protection, comfort, and compliance. Contact 3515 today to discuss your custom or bulk footwear needs.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What materials are used for impact-resistant toes? Steel, Aluminum, or Composite?

- What features do steel toe boots offer besides protection? Unlock All-Day Comfort and Enhanced Safety

- What are steel toe work boots and who should wear them? Essential PPE for Hazardous Jobs

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- What are key tips for fitting steel toe boots correctly? Ensure Safety and All-Day Comfort

- How has the perception of steel toe boots being bulky and heavy changed? Discover Lightweight Safety Footwear

- How can you optimize the fit of steel toe boots for better comfort? A Complete Guide to Custom Fit

- What common myth about steel toe caps is addressed in the article? Debunking the Amputation Fear