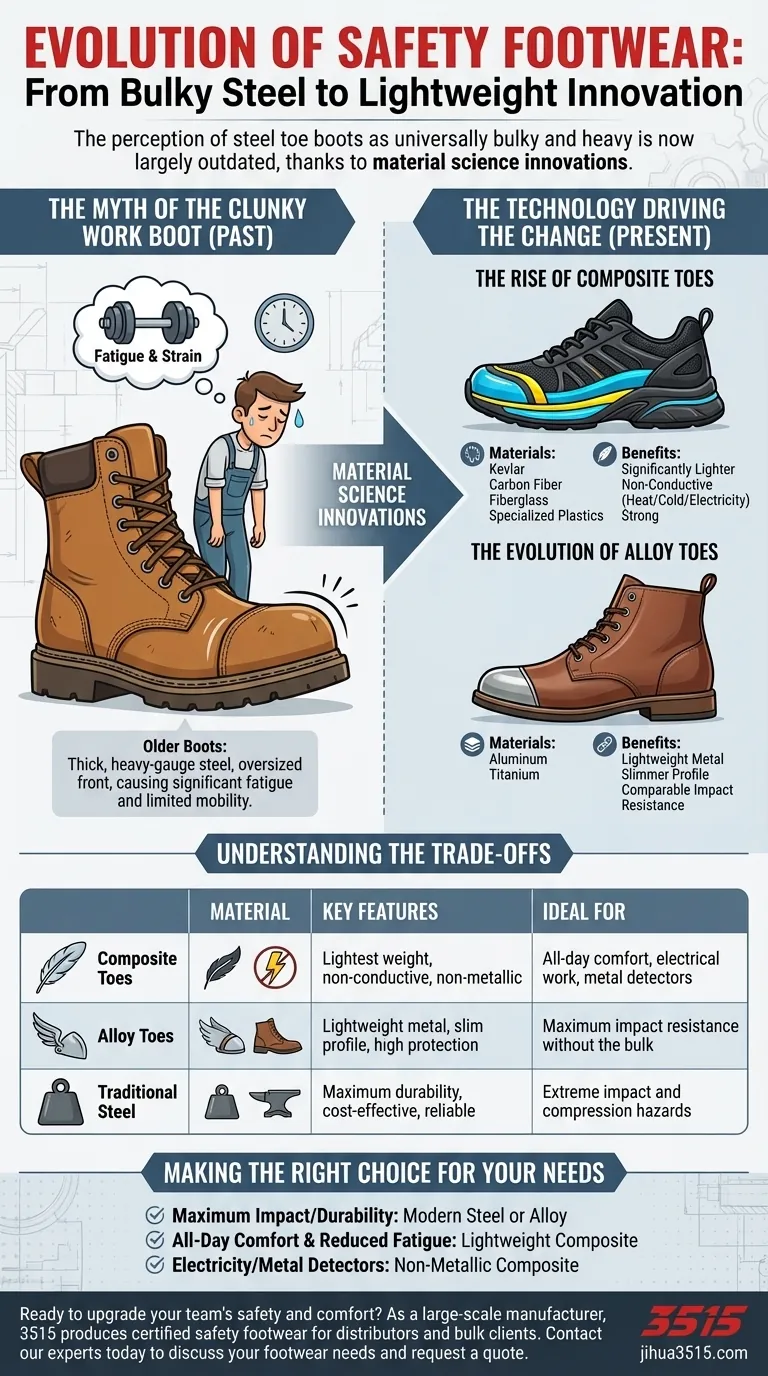

The perception of steel toe boots as universally bulky and heavy is now largely outdated. This shift is a direct result of significant material science innovations, particularly the development of composite materials and advanced metal alloys. These new technologies allow modern safety boots to offer robust protection in packages that are dramatically lighter, sleeker, and more comfortable than their predecessors.

The core reason for the change is simple: steel is no longer the only option. Modern safety footwear leverages advanced materials like carbon fiber, Kevlar, and lightweight alloys to deliver certified protection without the weight and bulk traditionally associated with steel toes.

The Myth of the Clunky Work Boot

For decades, the image of a work boot was inseparable from its heavy, oversized steel toe cap. This design wasn't a choice but a necessity based on the available technology.

Why Older Boots Were So Heavy

The original steel toe caps relied on thick, heavy-gauge steel to meet safety standards for impact and compression resistance. To accommodate this bulky cap, the entire front of the boot had to be oversized, leading to the clumsy, fatiguing footwear many still picture today.

The Impact on the Wearer

This traditional construction led to significant wearer fatigue over a long workday. The constant effort of lifting heavy boots could strain muscles and joints, while the lack of flexibility hindered natural movement and mobility.

The Technology Driving the Change

The breakthrough in safety footwear came from looking beyond traditional steel. Material science has provided alternatives that fundamentally change the relationship between protection and comfort.

The Rise of Composite Toes

Composite toes are non-metallic safety caps made from materials like Kevlar, carbon fiber, fiberglass, and specialized plastics.

Because these materials are incredibly strong for their weight, a composite toe cap can meet or exceed safety standards while being significantly lighter than a steel equivalent. They also do not conduct heat, cold, or electricity, making them ideal for a wider range of work environments.

The Evolution of Alloy Toes

For those who prefer a metal cap, modern alloys offer a lightweight alternative to steel. Safety toes made from materials like aluminum or titanium provide comparable impact resistance to steel but at a fraction of the weight.

These alloy toes allow for a much slimmer boot profile, often making them indistinguishable from standard footwear while still providing certified metallic protection.

Understanding the Trade-offs

While modern options have clear advantages in weight and comfort, it's important to understand the distinctions. The best choice always depends on the specific job and its hazards.

Steel vs. Composite: Key Differences

Steel toes often provide the highest level of resistance to extreme impact and compression, and they remain a cost-effective and highly reliable option.

Composite toes are the clear winner for weight savings and are non-conductive. However, after a single major impact event, the composite structure may be compromised and the boots should be replaced.

The Importance of Safety Ratings

Regardless of the material, the most critical factor is the boot's safety rating. Look for certifications like ASTM F2413 in the United States, which guarantees the footwear has been tested to meet specific standards for impact and compression. The material is the method; the safety rating is the proof.

Making the Right Choice for Your Needs

Choosing the right boot means matching the material's benefits to your daily tasks.

- If your primary focus is maximum impact resistance and durability: A modern, well-designed steel or alloy toe boot remains an excellent and reliable choice.

- If your primary focus is all-day comfort and reducing fatigue: Lightweight composite toe boots are the superior option and will have the biggest impact on your daily comfort.

- If you work around electricity or pass through metal detectors: Non-metallic composite toes are essential for safety and convenience.

Ultimately, today's safety footwear empowers you to choose certified protection without ever compromising on comfort or mobility.

Summary Table:

| Material | Key Features | Ideal For |

|---|---|---|

| Composite Toes | Lightest weight, non-conductive, non-metallic | All-day comfort, electrical work, metal detectors |

| Alloy Toes | Lightweight metal, slim profile, high protection | Maximum impact resistance without the bulk |

| Traditional Steel | Maximum durability, cost-effective, highly reliable | Extreme impact and compression hazards |

Ready to upgrade your team's safety and comfort?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of lightweight steel toe, alloy toe, and composite toe boots designed for modern workforces.

We can help you provide your team or customers with the perfect blend of protection, comfort, and style. Contact our experts today to discuss your footwear needs and request a quote.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How should one decide whether to wear steel-toe boots at work? Assess Your Risks for Optimal Foot Safety

- How do safety toes and steel toes compare? Choose the right protection for mobility or durability.

- What impact do steel toe caps have on toe skin health? Prevent Friction and Pressure in Your Safety Shoes

- What are the potential consequences of not wearing steel toe shoes? Avoid Severe Injuries & Financial Losses

- How does lacing technique affect steel toe boot comfort? Unlock a Perfect, Pain-Free Fit

- How does the weight of steel-toe boots compare to composite-toe boots? Uncover the Real Trade-Offs

- How do steel toe boots compare to composite toe boots? Choose the Right Toe for Your Job

- How do safety boots provide toe protection? A Guide to Steel vs. Composite Caps