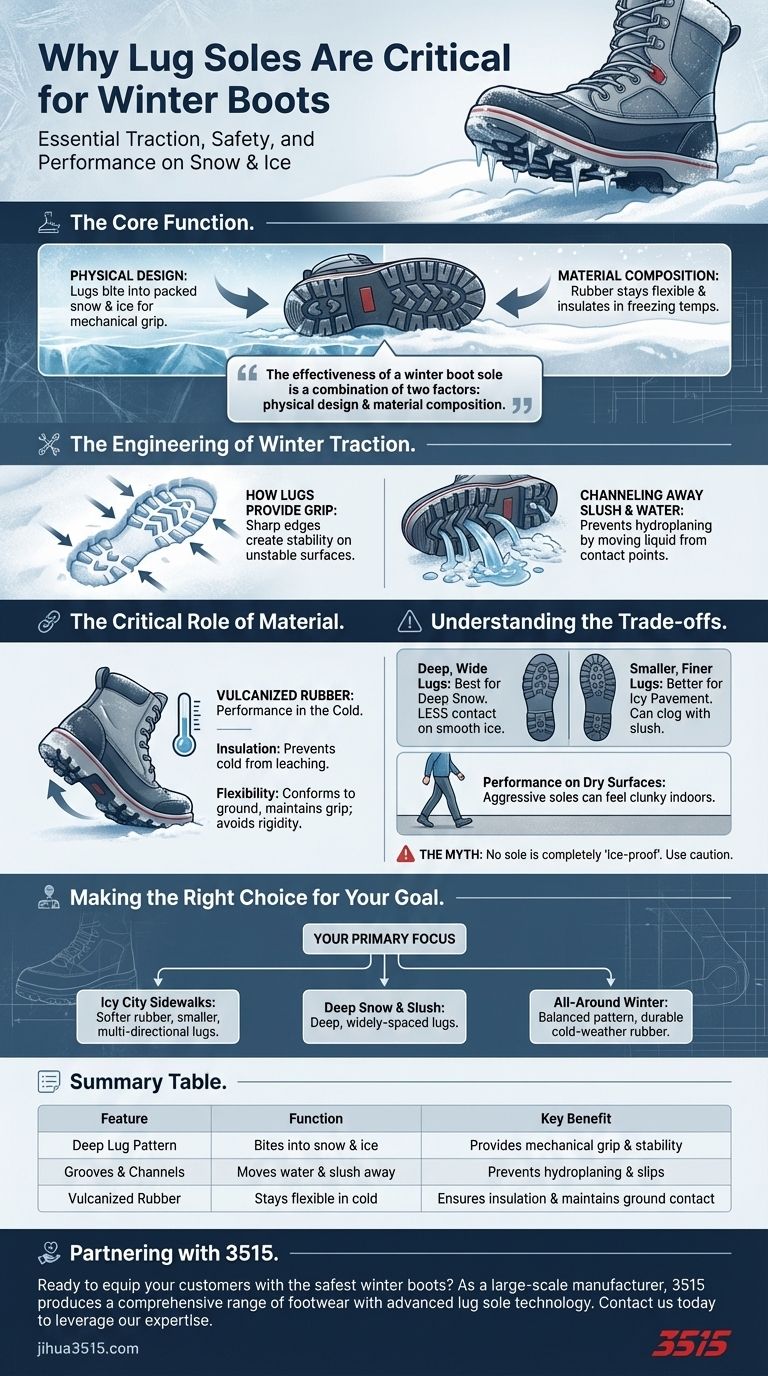

At their core, lug soles are the critical safety feature on winter boots, designed with deep, aggressive indentations to provide essential traction on slippery surfaces like snow and ice. This pattern allows the sole to grip uneven terrain, channel away slush, and significantly reduce the risk of slips and falls in hazardous conditions.

The effectiveness of a winter boot sole is a combination of two factors: the physical design of its lugs for mechanical grip and the material composition of its rubber for insulation and flexibility in freezing temperatures.

The Engineering of Winter Traction

To understand why lug soles are non-negotiable for winter, we need to look at how they solve the fundamental problems of walking on frozen or wet ground. It's a system that combines physics and material science.

How Lugs Provide Grip

The deep grooves and heavy indentations of a lug sole are engineered to interact directly with unstable surfaces. They create multiple sharp edges that bite into packed snow and ice, providing a level of stability that a flat sole cannot.

Channeling Away Slush and Water

The channels between the lugs serve a critical function: they move water and slush away from the sole's contact points. This prevents a layer of liquid from forming between your boot and the ground, a phenomenon known as hydroplaning, which is a major cause of slips on wet surfaces.

The Critical Role of Material

The pattern of the sole is only half the story. Winter boot soles are typically made from vulcanized rubber, a material specifically chosen for its performance in the cold.

This specialized rubber provides excellent insulation, preventing the cold from the ground from leaching into your feet. Crucially, it remains flexible at low temperatures, allowing the sole to conform to the ground and maintain its grip, whereas harder materials would become rigid and slick.

Understanding the Trade-offs

While essential for safety, the design of a lug sole involves certain compromises. Recognizing these will help you choose the right boot for your specific environment.

Not All Lug Patterns Are Equal

Deep, widely-spaced lugs are excellent for digging into deep snow but may offer less surface area contact on smooth, wet ice. Conversely, soles with many smaller, finer lugs might provide better grip on icy pavement but can get clogged with heavy slush or mud.

Performance on Dry Surfaces

An aggressive lug sole can feel clunky and stiff when walking on dry, clear pavement, such as inside a building. The deep treads that provide stability on snow can lead to a less comfortable walking experience on a flat, hard floor.

The Myth of an "Ice-Proof" Boot

It is vital to understand that no boot sole is completely slip-proof on sheer, smooth ice. Lug soles dramatically improve traction and reduce risk, but they are not a substitute for caution when walking in treacherous conditions.

Making the Right Choice for Your Goal

Your ideal winter boot sole depends entirely on the conditions you face most often.

- If your primary focus is navigating icy city sidewalks: Look for a sole with a softer rubber compound and a pattern of smaller, multi-directional lugs to maximize surface contact.

- If your primary focus is trekking through deep snow and slush: Prioritize boots with deep, widely-spaced lugs that can effectively shed debris and dig in for secure footing.

- If your primary focus is all-around winter warmth and safety: A balanced lug pattern made from a durable, cold-weather-rated vulcanized rubber offers the most versatile protection.

Choosing the right sole means building your winter safety from the ground up.

Summary Table:

| Feature | Function | Key Benefit |

|---|---|---|

| Deep Lug Pattern | Bites into snow and ice | Provides mechanical grip and stability |

| Grooves & Channels | Moves water and slush away | Prevents hydroplaning and slips |

| Vulcanized Rubber | Stays flexible in cold | Ensures insulation and maintains ground contact |

Ready to equip your customers with the safest winter boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of winter boots with advanced lug sole technology, ensuring superior traction and durability for any market need.

Contact us today to discuss your winter footwear requirements and leverage our manufacturing expertise.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the primary function of cowboy riding boots? Unpacking Their Essential Safety & Stability Role

- What are some insulation technologies used in winter boots? A Guide to Staying Warm and Dry

- What are the key features to look for in winter boots for comfort and warmth? Find Your Perfect Fit

- When should you condition cowboy boots? Master the Art of Leather Care and Longevity

- What are the requirements for standardized walking shoes in gait analysis? Ensure Data Integrity and Accuracy

- Why is ankle support important in hunting boots? Prevent Injury & Boost Stability

- What features make men's snow boots versatile? The 4 Key Elements for Any Winter Condition

- Why are counters sewn differently in cowboy boots? For Unmatched Strength in the Stirrup