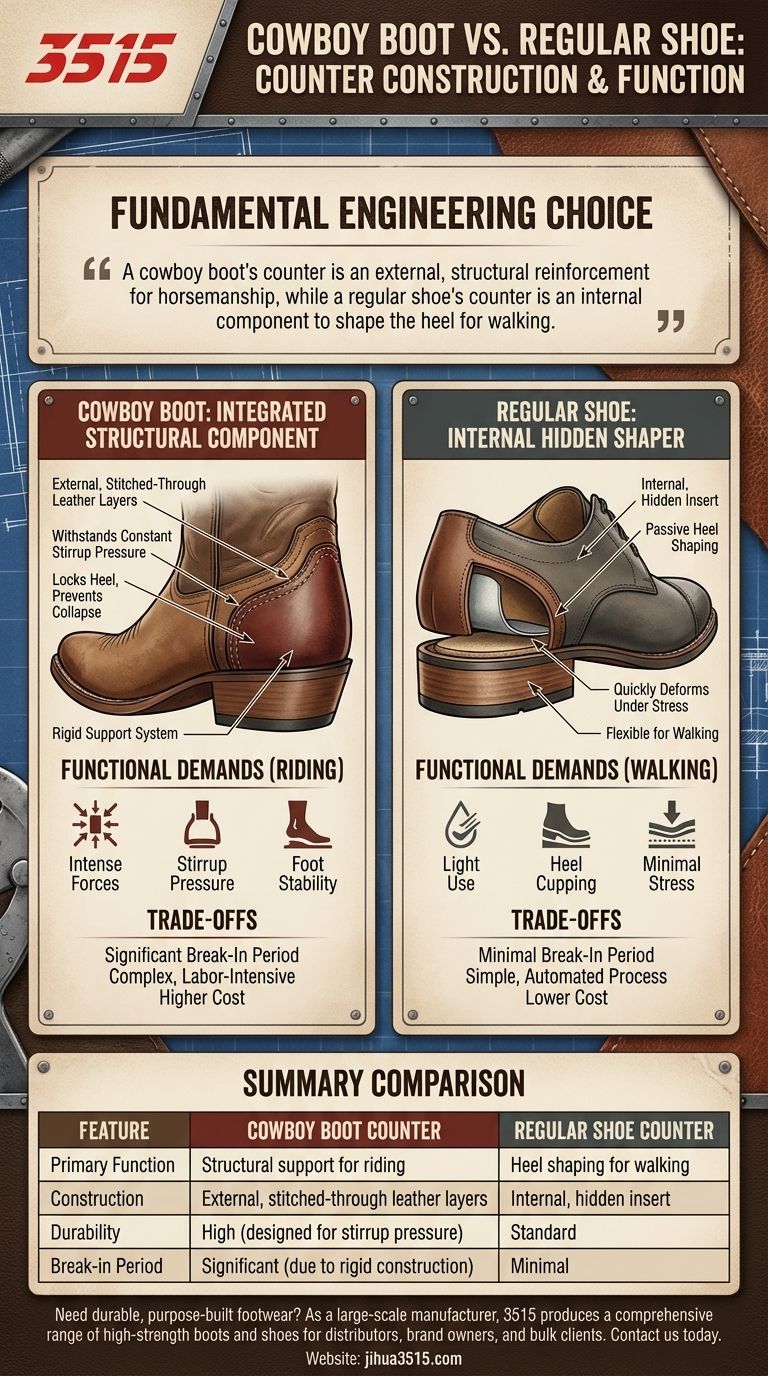

To put it simply, cowboy boot counters are sewn differently because a boot designed for riding demands exceptional strength that a regular shoe does not. This construction method integrates the counter into the boot's external structure, making it a load-bearing component designed to withstand the unique pressures of a stirrup, rather than just a hidden shaper.

The core difference isn't about style; it's a fundamental engineering choice. A cowboy boot's counter is built as an external, structural reinforcement for the demanding work of horsemanship, while a regular shoe's counter is simply an internal component to shape the heel for walking.

The Functional Demands of a Riding Boot

To grasp the design, you must first understand the intense and specific forces at play when a boot is used as intended—in a stirrup.

The Constant Pressure of the Stirrup

When riding, the rider's weight is often leveraged against the stirrup, placing immense and continuous pressure directly on the back and bottom of the boot's heel.

Preventing Heel Collapse

A standard shoe counter, typically a piece of thermoplastic or composite material inserted between the upper and the lining, would quickly deform and collapse under this stress. This would compromise the boot's integrity and the rider's stability.

Maintaining Foot and Ankle Stability

The entire heel area of a cowboy boot must function as a rigid support system. It locks the rider's heel in place, preventing the foot from sliding too far forward in the stirrup—a critical safety feature.

A Closer Look at the Construction Method

The traditional cowboy boot counter is not an afterthought; it is a foundational piece of the boot's architecture.

An Integrated Structural Component

Unlike in ordinary shoes, the thick, oak-tanned leather counter is stitched directly onto the outside of the boot's back panel. It is a visible and integral part of the boot's primary structure.

Double-Layer Reinforcement

For maximum durability, an additional counter piece is often stitched through both the outer counter and the boot's main panel. This creates a laminated structure that distributes force and resists tearing or distortion.

The Role of Heel Slides

Some high-end or heavy-duty boots may feature an additional slick leather or polymer "heel slide" on the counter. This piece is designed to reduce friction between the boot and the stirrup, further enhancing the longevity of the counter.

Understanding the Trade-offs

This robust construction method is superior for its intended purpose, but it comes with specific trade-offs compared to modern, mass-market footwear.

Rigidity and Break-In Period

The stiffness that provides such crucial support also means that a new pair of well-made boots will feel very rigid. This construction requires a significant break-in period for the thick leather to mold to the wearer's heel.

Labor, Complexity, and Cost

Stitching a multi-layer external counter is a far more complex and labor-intensive process than simply inserting a pre-molded counter during the lasting process. This is a primary contributor to the higher cost of traditionally made cowboy boots.

The Contrast with Standard Shoes

A regular shoe's counter is designed solely to cup the heel and prevent it from slipping while walking. It's hidden because its function is passive. The cowboy boot's counter is externalized because its function is active and structural.

What This Means When Choosing a Boot

Understanding the counter's construction allows you to evaluate a boot's quality and suitability for your needs.

- If your primary focus is equestrian use: This integrated, stitched-through counter construction is non-negotiable for safety, performance, and the longevity of your investment.

- If your primary focus is fashion or casual wear: Recognizing this feature allows you to appreciate the boot's authentic heritage and quality craftsmanship, even if you don't require its full functional strength.

- If you are evaluating a boot's quality: Look for the distinct stitching around the heel. A solid, uncrushable feel in this area is a clear sign of a boot built with traditional, durable methods.

Ultimately, the construction of the counter is a perfect illustration of how a tool is shaped by its purpose.

Summary Table:

| Feature | Cowboy Boot Counter | Regular Shoe Counter |

|---|---|---|

| Primary Function | Structural support for riding | Heel shaping for walking |

| Construction | External, stitched-through leather layers | Internal, hidden insert |

| Durability | High (designed for stirrup pressure) | Standard |

| Break-in Period | Significant (due to rigid construction) | Minimal |

Need durable, purpose-built footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of high-strength boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure the structural integrity and durability your customers demand. Contact us today to discuss your manufacturing needs!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What factors should riders consider when choosing between laces and Velcro on motorcycle boots? Find Your Perfect Fit.

- How do walking boots assist in gradual progression during recovery? A Guide to Safe Healing

- What are the benefits of choosing the right walking boots? Enhance Comfort, Safety & Joint Health

- Who are the Best Budget walking shoes recommended for? Ideal for Managing Foot Pain & Everyday Comfort

- Why is the toe box important in a walking shoe? Unlock Natural Foot Function & Comfort

- Why is it important to choose riding boots based on the discipline practiced? Maximize Safety & Performance

- What are the key specifications of the Best Overall walking shoes? The Blueprint for All-Day Comfort

- What DIY snake-proof material suggestions were proposed? Why Experts Advise Against Them