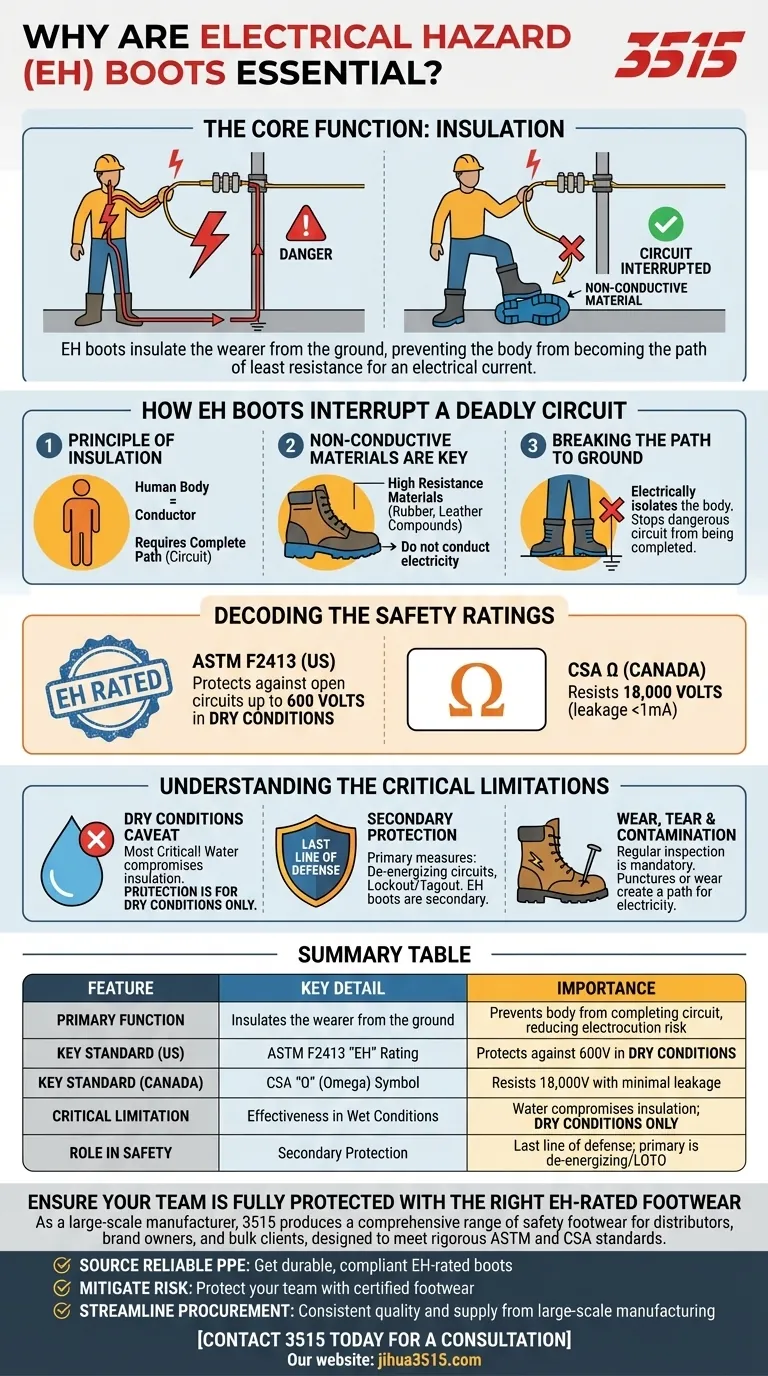

At their core, electrical hazard (EH) boots are essential because they insulate the wearer from the ground. This barrier of non-conductive material is designed to significantly reduce the risk of electrocution by preventing the wearer’s body from becoming the path of least resistance for an electrical current. They are a critical, life-saving piece of personal protective equipment (PPE) for anyone working near energized circuits or damaged electrical equipment.

The primary function of an EH-rated boot is not merely to protect your feet, but to interrupt a potentially fatal electrical circuit. However, it's crucial to understand that they are a secondary form of protection whose effectiveness is highly dependent on specific environmental conditions.

How EH Boots Interrupt a Deadly Circuit

To understand why EH boots are so critical, you first have to understand how electricity behaves. An electric current requires a complete path, or circuit, to flow.

The Principle of Insulation

The human body is an effective conductor of electricity. If a person simultaneously touches a live electrical source and a grounded surface, their body completes the circuit, and current will flow through them.

Non-Conductive Materials are Key

EH-rated boots are constructed from materials with very high electrical resistance, such as rubber and certain leather compounds. These materials do not conduct electricity well.

Breaking the Path to Ground

By wearing EH boots, you are electrically isolating your body from the ground. If you accidentally make contact with a live wire, the non-conductive soles prevent the current from flowing through your body to the ground, stopping a dangerous circuit from being completed.

Decoding the Safety Ratings

Not all work boots offer electrical protection. This is a specific feature verified by rigorous testing, and you must look for the official rating.

The ASTM F2413 Standard

In the United States, the most common standard is ASTM F2413. Boots marked "EH" meet this standard, signifying they can protect against open circuits up to 600 volts specifically in dry conditions.

The CSA "Omega" Symbol

In Canada, you will often see a white rectangle with an orange Greek letter omega (Ω). This indicates the footwear meets the Canadian Standards Association (CSA) requirement for resistance to 18,000 volts, with a leakage current not exceeding 1mA for 60 seconds.

Understanding the Critical Limitations

An EH boot is not an infallible shield. Acknowledging its limitations is just as important as wearing it.

The "Dry Conditions" Caveat

This is the most critical limitation. Water is a conductor of electricity. If your EH boots become wet, or if you are standing in water, their insulating properties are severely compromised or negated entirely.

Secondary vs. Primary Protection

EH boots are considered a secondary source of protection. Your primary safety measures should always be de-energizing circuits, following proper lockout/tagout procedures, and using insulated tools. EH boots are the last line of defense, not the first.

Wear, Tear, and Contamination

The boot's protective barrier can be compromised. Punctures from nails, embedded metal shavings, or excessive wear can create a path for electricity to travel through the sole. Regular inspection is mandatory.

Making the Right Choice for Your Goal

Selecting the correct footwear depends entirely on the specific hazards of your environment.

- If your primary focus is working directly with energized equipment: You must wear boots that are explicitly EH-rated and meet the appropriate ASTM or CSA standard for your region.

- If your primary focus is general construction or factory work: Do not assume a standard safety-toe boot provides electrical protection. You must verify it has the "EH" rating if any risk of contact with live circuits exists.

- If your primary focus is safety management: Your responsibility is to ensure workers not only have EH-rated boots but are also trained on their limitations, particularly the danger of wet conditions and the need for daily inspection.

Ultimately, treating EH boots as a specialized tool with a specific function is the key to ensuring workplace safety.

Summary Table:

| Feature | Key Detail | Importance |

|---|---|---|

| Primary Function | Insulates the wearer from the ground | Prevents the body from completing an electrical circuit, reducing electrocution risk |

| Key Standard (US) | ASTM F2413 "EH" Rating | Protects against open circuits up to 600 volts in dry conditions |

| Key Standard (Canada) | CSA "Ω" (Omega) Symbol | Resists 18,000 volts with minimal leakage current |

| Critical Limitation | Effectiveness in Wet Conditions | Water compromises insulation; protection is for dry conditions only |

| Role in Safety | Secondary Protection | A last line of defense; primary measures are de-energizing circuits and lockout/tagout |

Ensure Your Team is Fully Protected with the Right EH-Rated Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of EH-rated shoes and boots, designed to meet rigorous ASTM and CSA standards.

We help you:

- Source Reliable PPE: Get durable, compliant EH-rated boots for your workforce.

- Mitigate Risk: Protect your team from electrical hazards with certified footwear.

- Streamline Procurement: Benefit from our large-scale manufacturing for consistent quality and supply.

Don't compromise on safety. Let's discuss your specific needs and ensure your workers have the essential protection they require.

Contact 3515 today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What industries benefit most from soft-toe boots? Prioritize Comfort and Agility for Your Workforce

- What additional comfort features might work boots include? Engineered Systems for All-Day Performance

- What features are essential in cowboy boots for construction work? Prioritize Certified Safety & Durability

- What is Cement Construction in work boots? Unlocking the Secrets of Boot Durability & Comfort

- Why is engineered foot support important in work boots? Prevent Injuries & Boost Productivity

- Why are waterproof safety boots recommended for certain work environments? Essential Protection for Wet & Hazardous Jobs

- What factors do people commonly consider when choosing work boots? A Guide to Safety, Comfort & Fit

- What is the primary purpose of lace-to-toe boots? Achieve a Perfect, Customizable Fit