My main objective here is to give the user a complete understanding of "Cement Construction" in work boots, not just a definition, but why it matters in relation to other construction methods. I want to give them the tools to pick the right boot for their needs.

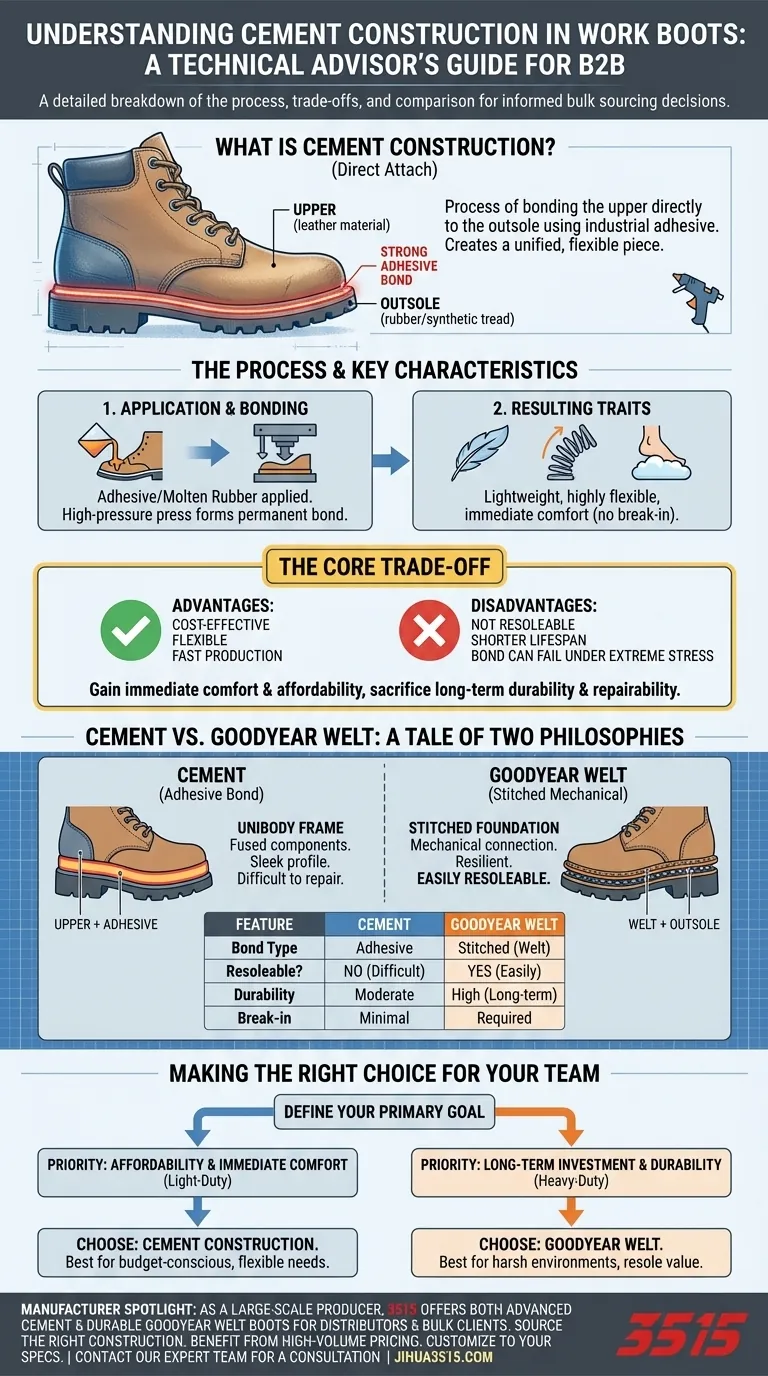

First, the direct answer: Cement Construction, at its core, is the process of bonding the boot's upper directly to the outsole using a strong adhesive. We'll also use "Direct Attach" or "Adhesive Construction" as synonyms. It's a simple, fast, and relatively inexpensive method.

Here's the key takeaway: Cement construction gives you flexibility and immediate comfort with a lower price. However, that comes with a major compromise: it's not designed to last as long as stitched boots, and when the sole wears out or detaches, you're looking at a new boot. Repair isn't really an option.

Now, let's explore how this works. We'll start by defining the process and move on to a comparison with welted construction.

The construction is straightforward: the boot's upper is glued to the outsole. This lack of stitching means the boot is inherently flexible and lightweight. These boots are generally more comfortable right out of the box because the bond allows for greater movement. And, because the process is quick, they're typically more affordable than boots made with stitching.

Now, let's contrast this with welted construction. The real difference is how the upper and sole are joined. Cement boots are essentially one unified piece, thanks to the adhesive. Welted boots, especially Goodyear Welt, use a welt, which is a strip of leather or rubber, that's stitched to both the upper and the outsole. This creates a much stronger, more durable bond. It also allows for resole of the boots, adding many years of life to the investment.

This stitching is critical for long-term wear. In a cement-constructed boot, under heavy use or stress, the adhesive bond is more likely to fail over time than a physical stitch.

Now, let's be upfront about the trade-offs. Cement boots are attractive because they're cost-effective and comfortable initially. No break-in period is an added bonus. But, the biggest drawback is repairability and lifespan. Once that sole is damaged, you're generally done with that boot. In harsh work environments or with demanding use, the adhesive bond may not hold up as long as stitching.

My goal is to give the user the information to make the best decision for their specific needs. Here's what that looks like:

- If you need a cost-effective boot that's immediately comfortable for light-duty work: Cement construction can be a fantastic option.

- If you need a long-term investment that can stand up to heavy work or harsh conditions: A Goodyear Welt or Stitch Down construction is the superior choice because it can be re-soled.

Ultimately, knowing the construction of your boots gives you the power to pick the right tool for the job. At its core, cement construction is a method used in work boots where the upper part of the boot is bonded directly to the outsole using a strong, high-performance adhesive. This process, also known as Direct Attach, creates a single, unified piece without the use of traditional stitching to hold the sole in place.

The central trade-off is clear: cement construction produces boots that are lightweight, flexible, and more affordable, but this comes at the expense of long-term durability and the ability to be resoled, a key feature of more traditional construction methods.

How Cement Construction Works

Cement construction is one of the most common methods for manufacturing footwear due to its speed and simplicity. Understanding the process reveals its inherent strengths and weaknesses.

The Bonding Process

The technique involves applying a powerful, industrial-grade adhesive or molten rubber to both the bottom of the boot's upper and the top of the outsole. The two pieces are then pressed together under high pressure to form a permanent, water-resistant bond.

The Resulting Characteristics

Because there is no rigid welt or heavy stitching, the final product is notably flexible and lightweight. This often translates to greater comfort right out of the box with minimal break-in time required.

Cement vs. Welted Construction: A Tale of Two Philosophies

To truly understand cement construction, it is best to compare it against its traditional counterpart: welted construction. The difference is fundamental to a boot's lifespan and performance.

The Cement Method: A Unified Bond

Think of a cement-constructed boot as a unibody frame. The upper and sole are permanently fused into one component. This makes for a sleek profile and excellent flexibility.

The Welted Method: A Stitched Foundation

In contrast, methods like the Goodyear Welt use a strip of leather, rubber, or plastic (the "welt") that is stitched to both the upper and the sole. This creates a durable, layered platform. This is the hallmark of premium, long-lasting work boots.

Why This Matters for Longevity

The physical stitches of a welted boot create a mechanical connection that is far more resilient to the torque, flexing, and abrasion a boot endures over its lifetime. An adhesive bond, while strong, is more susceptible to breaking down over time, especially in harsh conditions.

Understanding the Trade-offs

Choosing a boot construction method is not about "good" vs. "bad," but about aligning the boot's features with the demands of your job. Each method has distinct advantages and disadvantages.

Advantage: Cost and Comfort

The simplicity of the cementing process makes it faster and less expensive, resulting in a more affordable boot for the consumer. The inherent flexibility also means they are often more comfortable for individuals who spend a lot of time walking or crouching.

Disadvantage: Repairability and Lifespan

This is the most critical trade-off. Once the sole of a cement-constructed boot wears out or begins to separate from the upper, the boot is effectively at the end of its life. It cannot be easily or cost-effectively resoled without destroying the boot.

The Resole Factor

A boot with a Goodyear Welt, however, is built to be repaired. A cobbler can simply cut the stitches holding the old sole on and attach a new one, dramatically extending the boot's usable life for a fraction of the cost of a new pair.

Making the Right Choice for Your Goal

Your work environment and budget should be the deciding factors. The right choice depends entirely on what you prioritize.

- If your primary focus is affordability and comfort for light-duty work: Cement construction is a logical and cost-effective choice that provides excellent flexibility.

- If your primary focus is long-term investment and durability in demanding conditions: A Goodyear Welt construction is the superior option, as its resilience and ability to be resoled offer far greater value over time.

Understanding how your boots are held together is the first step toward choosing the right tool for the job.

Summary Table:

| Feature | Cement Construction | Goodyear Welt Construction |

|---|---|---|

| Primary Bonding Method | High-strength adhesive | Leather/Rubber welt stitched to upper & sole |

| Key Advantage | Lightweight, flexible, lower cost, immediate comfort | Extremely durable, water-resistant, can be resoled |

| Key Disadvantage | Difficult or impossible to resole; shorter lifespan | Heavier, stiffer, requires break-in, higher initial cost |

| Best For | Light-duty work, budget-conscious buyers, maximum flexibility | Heavy-duty work, long-term investment, harsh environments |

Need the Perfect Work Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including both advanced cement construction and durable Goodyear Welt methods.

We can help you:

- Source the right construction for your specific work environment and budget.

- Benefit from high-volume pricing without compromising on quality.

- Customize boots to meet your exact specifications and branding needs.

Let's build a safer, more productive workforce together.

Contact our expert team today for a consultation to discuss your project and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What does the 'MT' in ASTM F2413-18 stand for? Essential Metatarsal Protection Explained

- What are the key features for work boots for roofers? Prioritize Grip, Stability, and Safety

- What are the height differences between cowboy boots and Western work boots? Choose the Right Boot for Your Job

- What is the required height for NFPA wildland fire boots? The Essential 8-Inch Safety Standard

- Who is the ideal buyer for engineer boots? A Guide for the Rugged Style Enthusiast

- What are work boots designed for? Ultimate Protection, Support & Durability

- Why is leather conditioning important for fire boots? Extend Lifespan & Ensure Safety

- How long can work boots typically last with proper care? Maximize Your Investment's Lifespan