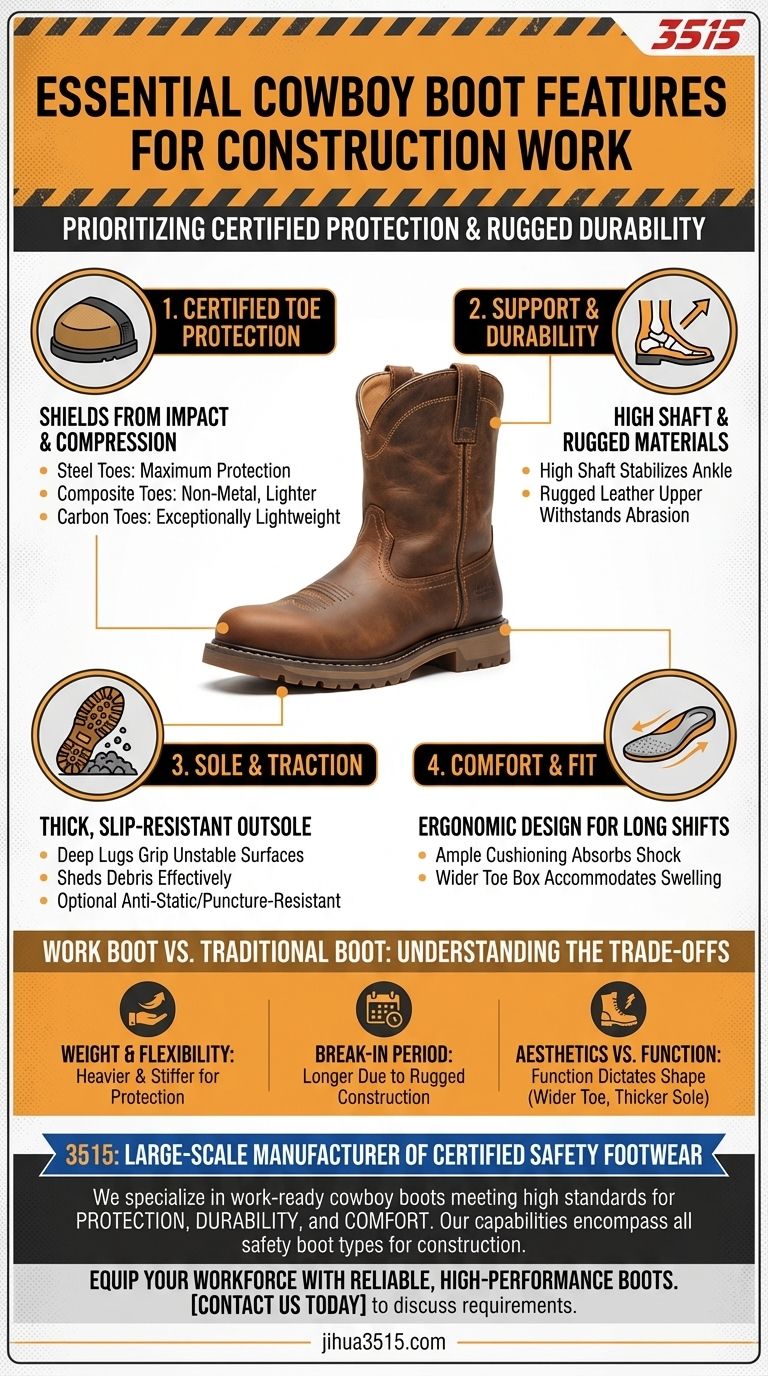

For construction work, your cowboy boots must prioritize certified protection and rugged durability above all else. The essential features are not about style but about safety: a certified protective toe (steel, composite, or carbon), a thick, high-traction, slip-resistant sole, and a high shaft that provides crucial ankle support on uneven ground.

Choosing a cowboy boot for a job site isn't an aesthetic choice; it's a decision about Personal Protective Equipment (PPE). The right boot blends the traditional high-shaft design with modern, certified safety technologies to protect you from the specific hazards of your work environment.

Beyond the Look: Deconstructing the Work-Ready Cowboy Boot

A true work boot's value is measured in its ability to prevent injury and provide stability, not in its classic silhouette. Every component must be engineered for the demanding and unpredictable conditions of a construction site.

The Non-Negotiable: Certified Toe Protection

The single most critical safety feature is a protective toe cap that meets national safety standards, such as those set by the ASTM (American Society for Testing and Materials).

This component shields your feet from catastrophic injury due to heavy falling objects or compression.

You will typically find three types:

- Steel Toes: The traditional standard, offering maximum protection.

- Composite Toes: Made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel and don't conduct electricity or temperature.

- Carbon Toes: A type of composite toe that is exceptionally lightweight while still meeting safety standards.

The Foundation: Sole and Traction

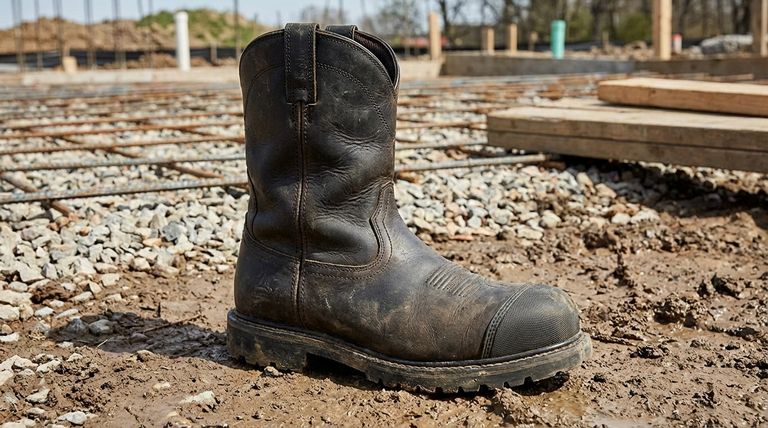

A construction site is an obstacle course of loose gravel, mud, spills, and uneven terrain. The boot's outsole is your primary point of contact and is critical for preventing slips and falls.

Look for boots with a thick, slip-resistant sole. The deep lugs and specific rubber compounds are designed to grip unstable surfaces and shed debris effectively.

Some job sites may also require anti-static or puncture-resistant properties in the sole for added protection against specific hazards.

The Structure: Support and Durability

The inherent design of a cowboy boot offers a distinct advantage in a work environment: ankle support.

The high shaft helps stabilize the ankle, reducing the risk of sprains and twists when navigating rebar, trenches, and debris.

The boot's upper must be made from rugged and durable materials, typically thick leather, to withstand the constant abrasion and punishment of a construction site.

The All-Day Requirement: Comfort and Fit

Safety features are useless if the boot is too uncomfortable to wear for a 10-hour shift. Modern work boots are designed with ergonomics in mind.

Good boots will feature ample cushioning and a supportive insole to absorb shock and prevent foot fatigue.

A wider toe box is also a key feature, as it accommodates the natural swelling of the feet that occurs over a long day of standing and working.

Understanding the Trade-offs: Work Boot vs. Traditional Boot

It is critical to understand that a work-rated cowboy boot is a different tool than a traditional one. Accepting the trade-offs is key to making the right choice.

Weight and Flexibility

Safety features add weight. A steel-toed, thick-soled work boot will be significantly heavier and stiffer than a standard dress or riding boot. This is the direct trade-off for impact protection and stability.

Break-in Period

The rugged leather and reinforced construction required for a durable work boot often mean a longer and more significant break-in period. Be prepared for this initial stiffness.

Aesthetics vs. Function

The shape of the boot, particularly the toe and the sole, is dictated by safety and function, not fashion. The sole will be thicker and the toe box wider and more rounded to accommodate the protective cap, altering the classic sleek profile.

Making the Right Choice for Your Job Site

Select your boot based on the primary hazards you face every day. Use this checklist to prioritize features according to your specific role on the construction site.

- If your primary focus is general construction: Prioritize a certified composite or steel toe and a high-traction, slip-resistant sole.

- If you work outdoors in wet or muddy conditions: Ensure the boot is explicitly rated as waterproof, often using a sealed membrane.

- If you are a welder or work with grinders: A full-leather upper and a sole rated for high heat are essential for protection against sparks.

- If you spend all day on concrete or hard surfaces: Look for superior cushioning and a supportive insole to prevent fatigue and joint pain.

Ultimately, the right boot is the one that meets the specific safety demands of your environment without compromise.

Summary Table:

| Essential Feature | Key Attribute | Why It Matters for Construction |

|---|---|---|

| Certified Toe | Steel, Composite, or Carbon | Protects feet from heavy falling objects and compression hazards. |

| Sole & Traction | Thick, Slip-Resistant, Deep Lugs | Prevents slips and falls on unstable, uneven, or wet surfaces. |

| Support & Durability | High Shaft, Rugged Leather Upper | Provides crucial ankle stability and withstands job site abrasion. |

| Comfort & Fit | Cushioned Insole, Wider Toe Box | Reduces foot fatigue and accommodates swelling during long shifts. |

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We specialize in crafting work-ready cowboy boots that meet the highest standards for protection, durability, and comfort. Our production capabilities encompass all types of safety boots and shoes tailored for the construction industry.

Ready to equip your workforce with reliable, high-performance cowboy boots? Contact our team today to discuss your specific requirements and discover how we can support your business with superior quality and manufacturing expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- How does the welt contribute to the longevity of boots? The Key to Decades of Serviceable Footwear

- What are the key roles of work boots in labor-intensive jobs? Essential for Safety, Performance & Comfort

- What does the ASTM F2413-18 certification ensure for work boots? A Guide to Decoding Safety Ratings

- How are work boot insulation ratings measured? A Guide to Choosing the Right Warmth

- How do moc toe boots differ from round-toe boots? A Guide to Rugged vs. Versatile Style

- Why is it important to take care of work boots? Protect Your Investment, Safety, and Comfort

- Why is it important to dry winter boots after use? Protect Your Feet & Extend Boot Life

- What materials are used to ensure fire boot durability and safety? Key Components for Ultimate Protection