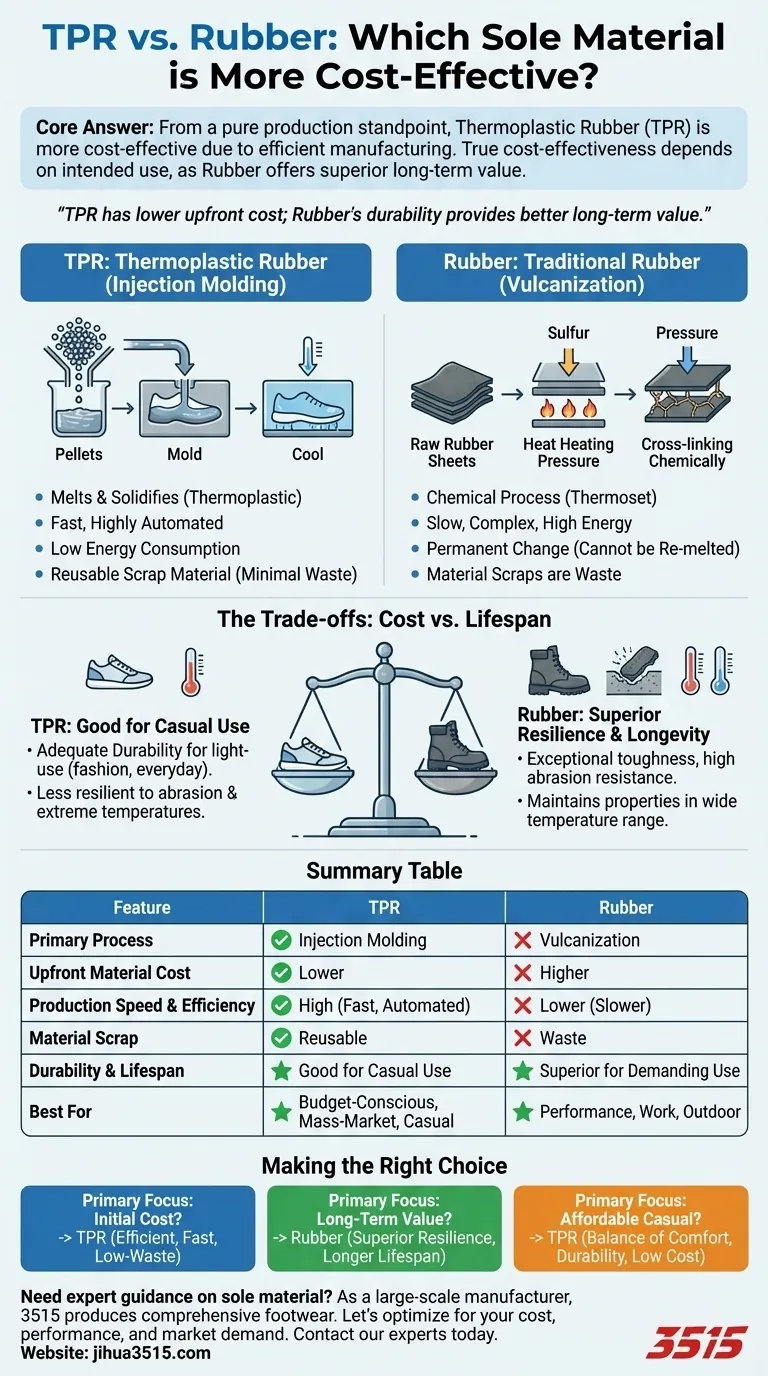

From a pure production standpoint, Thermoplastic Rubber (TPR) is the more cost-effective sole material. Its lower cost is primarily due to a more efficient and less energy-intensive manufacturing process compared to traditional rubber, making it a go-to choice for budget-conscious and mass-market footwear.

While TPR offers a lower upfront cost, true cost-effectiveness depends entirely on the intended use. Rubber's superior durability and performance often translate to better long-term value in demanding applications, making the initial price only one part of the equation.

The Core Reason for the Cost Difference: Manufacturing

The fundamental price disparity between TPR and rubber is rooted in how they are made. The two materials undergo vastly different production processes, which directly impacts labor, energy, and material waste costs.

TPR: The Advantage of Injection Molding

TPR is a thermoplastic, meaning it can be melted down with heat and then solidified by cooling without chemical change. This property allows for a highly efficient process called injection molding.

Pellets of TPR are melted and injected into a sole-shaped mold. The process is fast, highly automated, and requires relatively low energy. Crucially, any scrap material can be re-melted and reused, significantly minimizing waste.

Rubber: The Intensity of Vulcanization

Traditional rubber, on the other hand, is a thermoset material. It must undergo a chemical process called vulcanization, where it's heated with sulfur to create strong cross-links between polymer chains.

This process is more complex, slower, and consumes far more energy than injection molding. Once rubber is vulcanized, it cannot be melted down and reformed, meaning any manufacturing scraps are waste.

Understanding the Trade-offs: Cost vs. Lifespan

A lower initial price does not always mean a product is more "cost-effective." The true value is determined by comparing the upfront cost to the product's functional lifespan.

TPR's Durability Profile

TPR soles offer adequate durability for casual, light-use footwear like fashion sneakers or everyday shoes. Their wear resistance is good for the price, but they are less resilient than rubber against heavy abrasion or extreme temperatures.

Rubber's Superior Resilience

Vulcanized rubber is known for its exceptional toughness and longevity. It offers superior abrasion resistance, meaning it wears down much more slowly under friction. This makes it the standard for performance, work, and outdoor footwear where durability is non-negotiable.

The Impact of Environment

Rubber maintains its physical properties, like grip and flexibility, across a much wider range of temperatures. TPR can become stiff and brittle in the cold or overly soft in high heat, which can impact both comfort and a shoe's lifespan.

Making the Right Choice for Your Goal

Your definition of "cost-effective" must align with your specific performance needs and priorities.

- If your primary focus is minimizing initial manufacturing cost: TPR is the clear winner due to its efficient, fast, and low-waste injection molding process.

- If your primary focus is long-term value and user satisfaction: Rubber is the superior investment, as its resilience against wear and environmental factors leads to a much longer product lifespan.

- If your primary focus is creating affordable, casual footwear: TPR provides an excellent balance of comfort, acceptable durability, and low cost for non-demanding, everyday use.

Ultimately, choosing the right material requires matching its inherent production costs and performance characteristics to your specific goals.

Summary Table:

| Feature | Thermoplastic Rubber (TPR) | Traditional Rubber |

|---|---|---|

| Primary Manufacturing Process | Injection Molding | Vulcanization |

| Upfront Material Cost | Lower | Higher |

| Production Speed & Efficiency | High (Fast, Automated) | Lower (Slower, More Complex) |

| Material Scrap | Reusable | Waste |

| Durability & Lifespan | Good for Casual Use | Superior for Demanding Use |

| Best For | Budget-Conscious, Mass-Market, Casual Footwear | Performance, Work, Outdoor Footwear |

Need expert guidance on the right sole material for your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots. We can help you navigate material selection to optimize for cost, performance, and market demand, ensuring your products are both competitive and high-quality.

Contact our experts today for a consultation and let's build better footwear together.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene