To determine if a shoe is non-slip, you should first look for an explicit "slip-resistant" statement on the product tag, in the online product description, or inscribed on the shoe's sole or tongue. This official labeling is the most direct confirmation of the shoe's intended purpose and safety rating.

The most reliable way to verify a shoe's non-slip capability is to look for third-party certification codes, like ASTM F-2913. If certification isn't available, you must evaluate the shoe's physical design, specifically the outsole material and tread pattern.

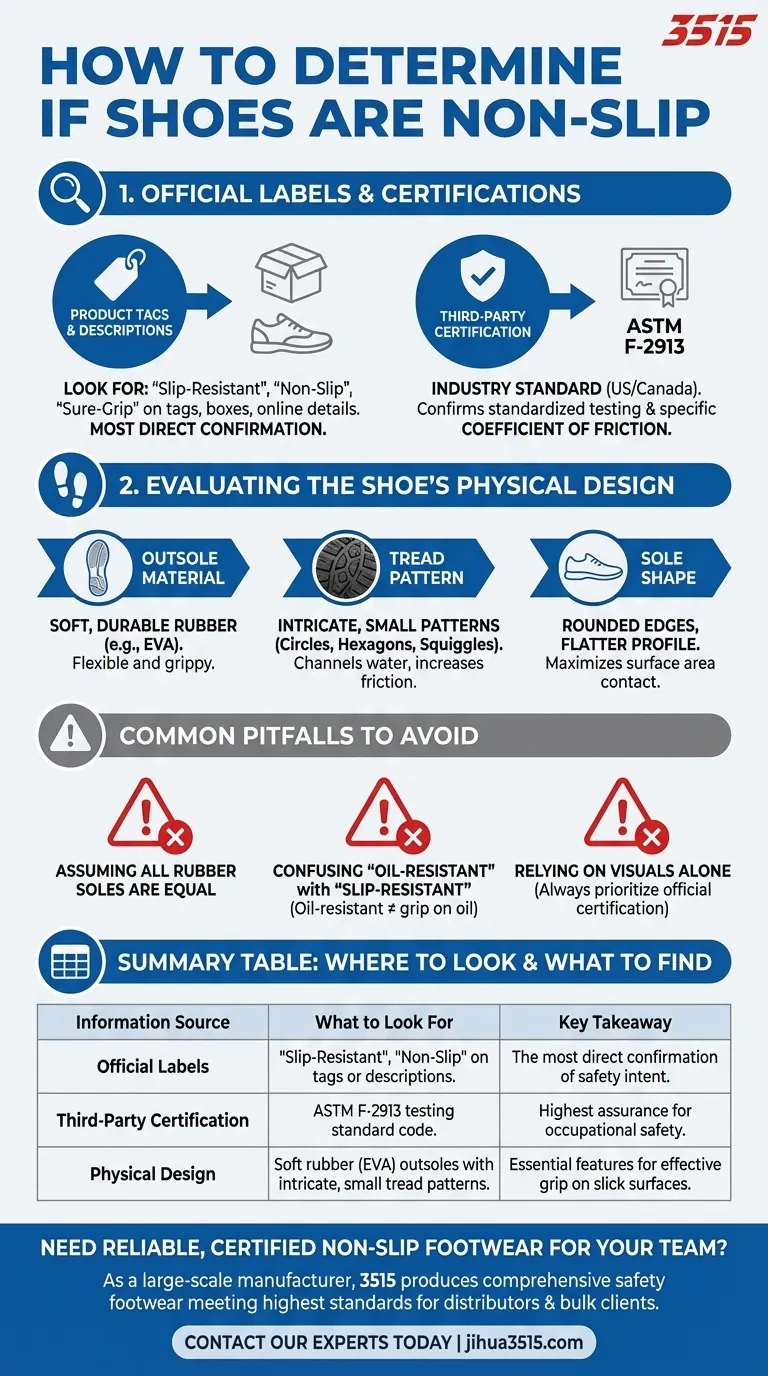

Official Labels and Certifications

The most trustworthy indicators are the official statements and ratings provided by the manufacturer or independent testing bodies. These remove the guesswork from your decision.

Product Tags and Descriptions

When shopping, your first check should always be the product's official information. Look for keywords like "slip-resistant," "non-slip," or "sure-grip." This information is typically found on the box, on a tag attached to the shoe, or prominently in the online product details.

Third-Party Certification

For occupations where safety is critical, look for proof of third-party testing. In the United States and Canada, the industry standard is ASTM F-2913.

This certification confirms the shoe has been tested on various surfaces and meets a specific coefficient of friction (a measure of grip), ensuring it performs under standardized hazardous conditions.

Evaluating the Shoe's Physical Design

If official labels are unclear or unavailable, you can assess the shoe's physical characteristics. A true non-slip shoe is engineered with specific materials and patterns designed to maximize grip.

The Outsole Material

The outsole—the part of the shoe that contacts the ground—should be made of a soft, durable rubber. Many high-quality non-slip shoes use EVA (ethylene vinyl acetate) rubber, which remains flexible and grippy.

The Tread Pattern

Examine the pattern on the bottom of the sole. Effective non-slip treads feature small, intricate patterns, such as tiny circles, hexagons, or squiggles.

These small patterns create more friction and are designed to channel water and other liquids out from under the shoe, maintaining contact with the ground. A wide, blocky tread is less effective on slick, wet surfaces.

The Sole Shape

Look for a sole design with slightly rounded edges and a flatter overall profile. This design maximizes the surface area in contact with the floor, which helps improve stability and prevent slipping.

Common Pitfalls to Avoid

Not all "work shoes" are truly slip-resistant. Understanding common misconceptions can prevent a poor choice.

Assuming All Rubber Soles are Equal

A rubber sole does not automatically mean a shoe is non-slip. The specific compound of the rubber and the design of the tread are what provide the slip-resistant properties.

Confusing "Oil-Resistant" with "Slip-Resistant"

While often found together, these terms mean different things. "Oil-resistant" means the sole material won't degrade when exposed to oil, but it does not guarantee grip on an oily surface. You need the "slip-resistant" rating for safety.

Relying on Visuals Alone

While a good tread pattern is a positive sign, it is not a substitute for an official slip-resistant certification. Always prioritize shoes that have been formally tested and rated.

Making the Right Choice for Your Goal

Your specific needs should guide your evaluation.

- If your primary focus is maximum occupational safety (e.g., restaurant, healthcare): Prioritize shoes that explicitly state they meet a third-party standard like ASTM F-2913.

- If your primary focus is general daily wear with improved traction: Look for shoes marketed as "slip-resistant" and visually confirm they have a soft rubber sole with a dense, intricate tread pattern.

Ultimately, choosing the right footwear is a critical step in ensuring your personal safety on any surface.

Summary Table:

| Information Source | What to Look For | Key Takeaway |

|---|---|---|

| Official Labels | "Slip-Resistant," "Non-Slip" on tags or descriptions. | The most direct confirmation of safety intent. |

| Third-Party Certification | ASTM F-2913 testing standard code. | Highest assurance for occupational safety. |

| Physical Design | Soft rubber (EVA) outsoles with intricate, small tread patterns. | Essential features for effective grip on slick surfaces. |

Need reliable, certified non-slip footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair meets the highest standards for slip resistance, durability, and comfort.

Let us help you equip your workforce with confidence. Contact our experts today to discuss your specific needs and explore our catalog.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How are slip-resistant shoes certified for safety? Ensure Workplace Safety with Certified Footwear

- What are slip-resistant shoes? Your Guide to Safer Footwear for Hazardous Floors

- What makes the slip-resistant outsole effective? Unlock the Science of Grip and Safety

- How are slip-resistant safety shoes classified? SRA, SRB, SRC Ratings Explained

- What benefits do slip-resistant shoes provide? Slash Injury Rates and Boost Workplace Safety

- How do safety boots prevent slips and falls? Engineered for Maximum Traction and Stability

- Which sole materials are recommended for wet concrete floors? Choose the Safest Grip for Your Team

- How does the floor type affect slip-resistant shoe choice? Match Your Sole to Your Surface