In short, slip-resistant shoes are certified by undergoing rigorous, standardized testing performed by independent organizations. These tests measure the shoe's coefficient of friction on various surfaces to ensure they meet specific safety benchmarks, such as the widely recognized ASTM F3445 standard. This process provides an objective measure of a shoe's ability to prevent slips and falls in hazardous environments.

The core principle of certification is not about the shoe's material alone, but about its tested, verifiable performance. It replaces subjective claims of "good grip" with objective data, ensuring the footwear reliably reduces the risk of slips on slick surfaces.

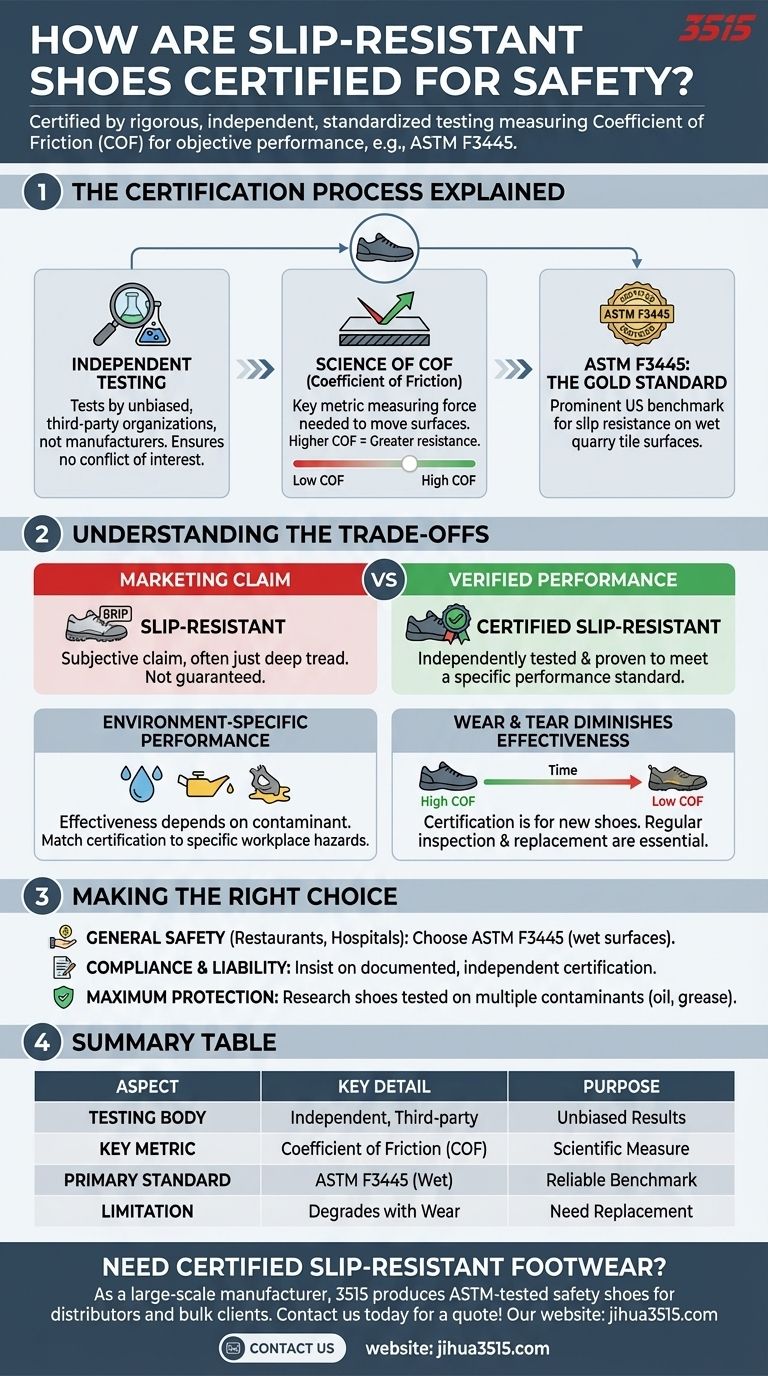

The Certification Process Explained

Certification transforms a simple safety claim into a trusted guarantee. It involves a systematic evaluation of a shoe's outsole performance under controlled, repeatable conditions that simulate real-world hazards like wet or oily floors.

The Role of Independent Testing

Certification is not performed by the shoe manufacturer. Instead, it relies on independent, third-party organizations to conduct the tests.

This separation is crucial. It ensures the results are unbiased and that the shoe genuinely meets the required safety criteria without any conflict of interest.

The Science of Slip Resistance: Coefficient of Friction

The key metric in testing is the coefficient of friction (COF). This is a scientific measure of the force required to move one surface over another.

A higher COF means greater resistance to slipping. Certification tests precisely measure a shoe's COF on standardized wet, oily, or otherwise slick surfaces to see if it meets the minimum threshold for safety.

ASTM F3445: The Gold Standard

While various standards exist, the ASTM F3445 standard is a prominent benchmark for slip-resistant footwear in the United States.

Shoes certified under this standard have passed specific tests for slip resistance on quarry tile surfaces under wet conditions. This provides a clear, reliable indicator of performance for workplace safety.

Understanding the Trade-offs

While certification is a powerful tool, it's essential to understand its context and limitations. Not all "slip-resistant" shoes are created equal, and certification doesn't eliminate all risk.

"Slip-Resistant" vs. Certified

The term "slip-resistant" can be used by any manufacturer, often as a marketing claim. It might simply refer to a shoe with a deep tread pattern.

In contrast, "certified slip-resistant" means the shoe has been independently tested and proven to meet a specific performance standard. This is the mark of true safety footwear.

Environment-Specific Performance

A shoe certified for wet conditions may not perform equally well on oily or greasy surfaces. The effectiveness of a shoe's outsole is highly dependent on the type of contaminant on the floor.

Therefore, it's critical to match the shoe's certified capabilities to the specific hazards present in your environment.

Wear and Tear Diminishes Effectiveness

The slip-resistant properties of any shoe degrade over time. As the specialized rubber sole and tread pattern wear down, the coefficient of friction decreases.

Certification applies to the shoe when it is new. It does not guarantee the same level of performance after months of heavy use. Regular inspection and replacement are essential parts of any safety program.

Making the Right Choice for Your Goal

Selecting the right footwear requires matching the certification to your specific safety needs.

- If your primary focus is general workplace safety (e.g., restaurants, hospitals): Look for shoes specifically certified to the ASTM F3445 standard, as this ensures proven performance on common wet surfaces.

- If your primary focus is compliance and liability reduction: Insist on footwear with documented, independent certification to a recognized standard, as this provides a verifiable basis for your safety protocols.

- If your primary focus is maximum protection in varied conditions: Go beyond a single certification and research shoes tested on multiple surface types, including oily and greasy contaminants.

Ultimately, proper certification provides the confidence that your footwear is a reliable tool, not just an accessory, in preventing slips and falls.

Summary Table:

| Certification Aspect | Key Detail |

|---|---|

| Testing Body | Independent, third-party organizations |

| Key Metric | Coefficient of Friction (COF) |

| Primary Standard | ASTM F3445 (wet surfaces) |

| Purpose | Objective verification of slip resistance |

| Limitation | Performance degrades with wear and tear |

Need certified slip-resistant footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-tested safety shoes and boots for distributors, brand owners, and bulk clients. We ensure your team has reliable, certified protection against slips and falls.

Contact us today to discuss your safety footwear needs and request a quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data