The type of floor fundamentally dictates your choice of slip-resistant shoe because no single sole is effective on every surface. The critical factor is not just the floor material itself, but the contaminants—like water, oil, or dust—that create the slip hazard. A shoe designed to grip a wet tile floor may fail completely on an oily one.

Choosing the right slip-resistant shoe requires you to look beyond the floor itself. The goal is to match the shoe's sole material and tread pattern to the specific contaminants and conditions of your unique work environment.

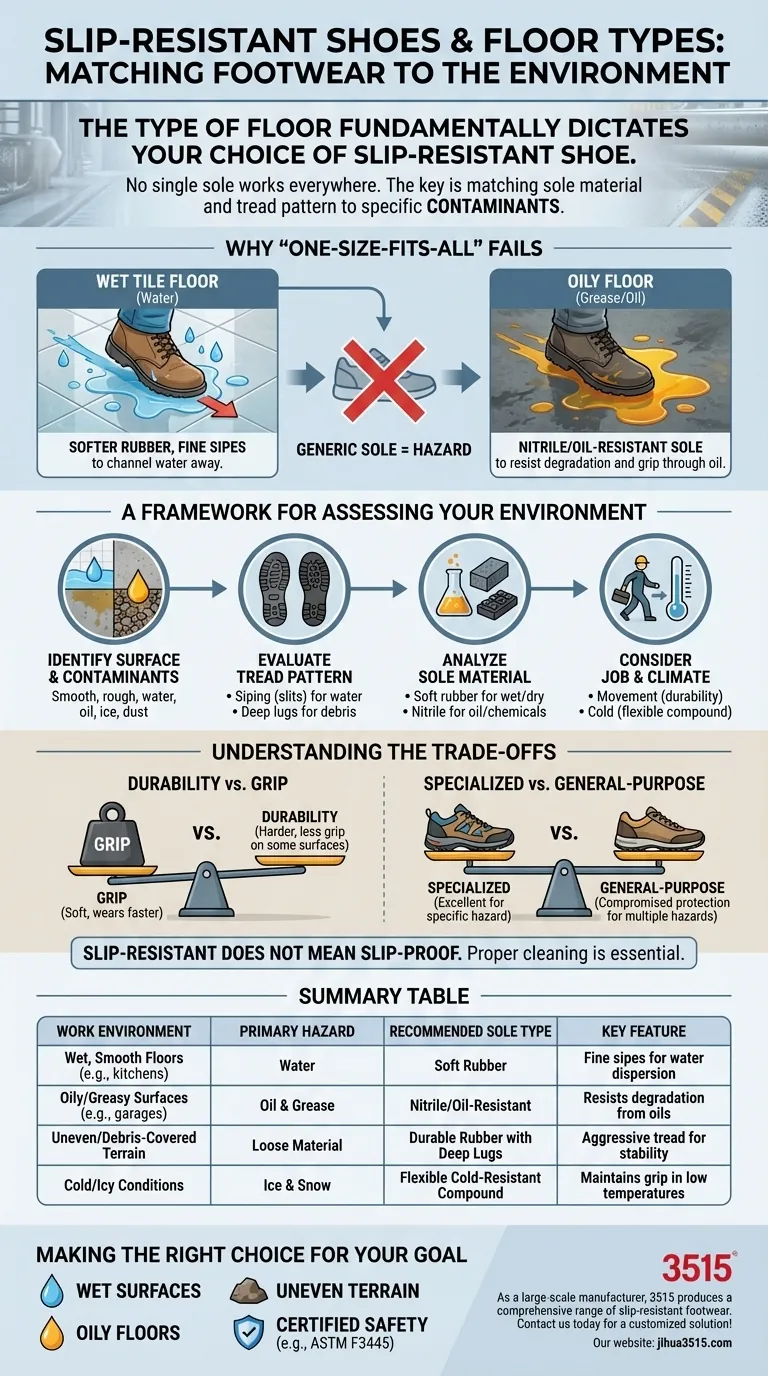

Why a "One-Size-Fits-All" Approach Fails

The effectiveness of a slip-resistant shoe depends on its ability to maintain friction with the walking surface. Different floor types and, more importantly, the substances on them, interfere with this friction in unique ways.

The Critical Role of Contaminants

The most common workplace slip hazards are fluids like water and oil.

A sole designed for water-covered surfaces typically uses a softer rubber with intricate, shallow tread patterns. These patterns work by channeling water away from the point of contact, much like the tread on a car tire.

Oily or greasy surfaces require a different solution. Oil is more viscous than water and can degrade certain types of rubber. Shoes for these conditions need a specific sole compound (like nitrile rubber) that resists oil and a tread pattern that can still make contact with the floor through the slick substance.

The Impact of Surface Texture

The physical texture of the floor also matters.

A shoe that performs well on a smooth, hard surface like polished concrete needs a sole with a large contact area to maximize grip.

Conversely, for uneven or debris-covered terrain like a construction site, you need a sole with deep, aggressive lugs. These provide stability and grip on loose material, where surface contact is less important than digging in.

A Framework for Assessing Your Environment

To select the right footwear, you must perform a simple risk assessment of your workspace. Consider the complete picture of your daily conditions.

Identify the Surface Conditions

Start by cataloging the primary surfaces you walk on. Are they smooth tile, sealed concrete, grating, or rough outdoor ground?

Most importantly, what are they covered in? Note the presence of water, oil, grease, dust, or ice. This is the single most important factor.

Evaluate the Sole's Tread Pattern

Look at the bottom of the shoe. A dense pattern of tiny slits, or siping, is excellent for dispersing water on smooth floors.

Deep, widely-spaced lugs are designed to grip soft or uneven surfaces and prevent mud or debris from clogging the sole.

Analyze the Sole Material

Soft rubber is often the best choice for providing maximum grip on clean, dry, or wet surfaces.

For environments with oils and chemicals, you must look for nitrile or other specifically designated oil-resistant compounds. Standard rubber can swell or break down when exposed to these substances, destroying its slip-resistant properties.

Consider Your Job Role and Climate

Your daily tasks influence wear and tear. A worker who is constantly moving and pivoting needs a more durable sole than one who is mostly stationary.

Climate introduces another variable. If you work in cold environments, you need a sole material that remains flexible and doesn't harden in low temperatures, which is critical for maintaining grip on ice or snow.

Understanding the Trade-offs

There is no perfect shoe, only the right shoe for a specific application. Understanding the compromises is key to making an informed decision.

Durability vs. Grip

Often, the softest and "grippiest" sole compounds are also the least durable. A shoe that provides exceptional traction on a wet kitchen floor may wear out quickly if used on abrasive surfaces like asphalt or concrete.

Specialized vs. General-Purpose

A highly specialized shoe designed for one hazard may offer poor protection against another. The best oil-resistant kitchen shoe is likely a poor choice for icy outdoor conditions. If you work across multiple environments, you may need more than one type of footwear.

The Limits of "Slip-Resistant"

Remember that "slip-resistant" does not mean "slip-proof." These shoes are designed to significantly reduce the risk of falling, but they cannot eliminate it entirely. Proper cleaning of both the floor and the shoe soles is essential for maintaining performance.

Making the Right Choice for Your Goal

Ultimately, your selection should be a direct response to your most common working conditions.

- If your primary focus is wet surfaces: Choose a soft rubber sole with a dense pattern of fine sipes or channels to push water away.

- If your primary focus is oily or greasy floors: Insist on a shoe with a nitrile or oil-resistant sole compound to prevent material degradation.

- If your primary focus is uneven terrain or loose debris: Prioritize a durable sole with deep, aggressive lugs that provide stability and traction.

- If you need a certified standard of safety: Look for footwear that meets established industry standards, such as the ASTM F3445 rating.

By methodically matching the shoe's design to your specific work conditions, you can significantly reduce the risk of slips and falls.

Summary Table:

| Work Environment | Primary Hazard | Recommended Sole Type | Key Feature |

|---|---|---|---|

| Wet, Smooth Floors (e.g., kitchens) | Water | Soft Rubber | Fine sipes for water dispersion |

| Oily/Greasy Surfaces (e.g., garages) | Oil & Grease | Nitrile/Oil-Resistant | Resists degradation from oils |

| Uneven/Debris-Covered Terrain (e.g., construction) | Loose Material | Durable Rubber with Deep Lugs | Aggressive tread for stability |

| Cold/Icy Conditions | Ice & Snow | Flexible Cold-Resistant Compound | Maintains grip in low temperatures |

As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots tailored to your specific work environments—from wet kitchens to oily industrial floors. Let us help you equip your team with the right footwear to minimize slip risks. Contact us today for a customized solution!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments