In short, slip-resistant shoes are a specialized category of footwear engineered with specific outsole materials and tread patterns designed to provide superior grip on wet, oily, or otherwise slippery surfaces. Unlike standard shoes, their sole purpose is to increase traction and reduce the risk of falls in hazardous environments.

True slip-resistance isn't a marketing term; it's a result of deliberate engineering. The effectiveness of these shoes comes from a system of three key elements: a soft sole compound for grip, a deep tread pattern that channels liquids away, and often an official safety standard certification.

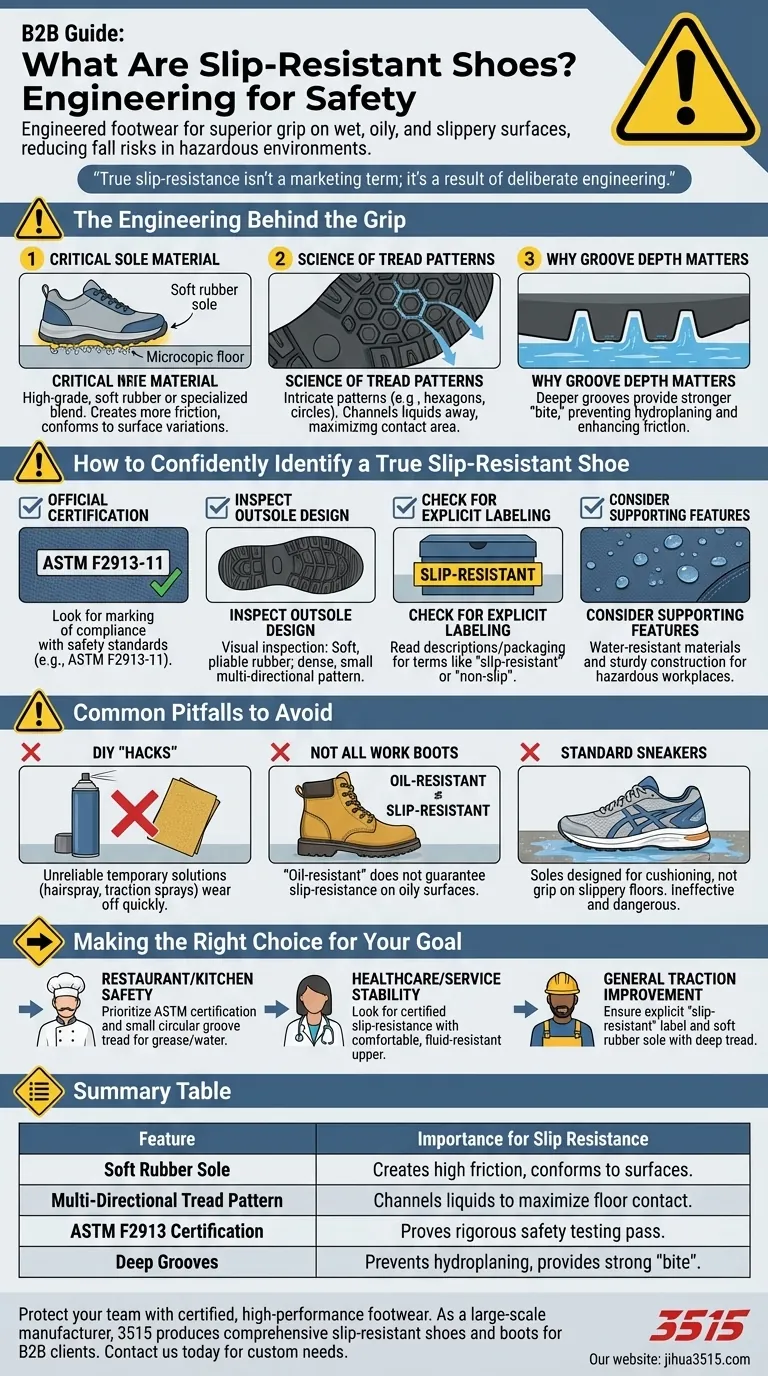

The Engineering Behind the Grip

To understand slip-resistant shoes, you must look at their core design principles. The magic isn't in one feature but in how several components work together to maintain contact between the shoe and the floor, even when contaminants like water or grease are present.

The Critical Role of Sole Material

The foundation of a non-slip shoe is its outsole material. Most are made from high-grade, soft rubber or a specialized synthetic blend.

This softer compound creates more friction than the hard, rigid soles found on many fashion or athletic shoes, allowing it to better conform to and grip microscopic variations in a floor's surface.

The Science of Tread Patterns

The pattern carved into the bottom of the shoe is crucial for performance on wet or oily floors.

Effective slip-resistant shoes feature an intricate tread pattern of small, interlocking shapes like hexagons or circles. These patterns create channels that push liquids out and away from the sole, maximizing the contact area between the rubber and the floor itself. This functions much like the treads on a car tire dispersing water on a wet road.

Why Groove Depth Matters

Beyond the shape of the tread, its depth is a key factor.

Deeper grooves provide a stronger "bite" on the surface, creating higher friction and preventing a thin layer of liquid from causing the shoe to hydroplane. This design ensures that the tread can effectively channel away contaminants.

How to Confidently Identify a True Slip-Resistant Shoe

With many shoes claiming enhanced traction, knowing how to spot a genuinely effective pair is essential for safety. You can verify a shoe's slip-resistant properties by looking for a few key indicators.

Look for Official Certification

The most reliable indicator is a marking of compliance with a safety standard. In the United States, look for a label indicating the shoe meets ASTM F2913-11 (or a more recent version) standards. This proves it has passed rigorous, standardized testing for slip resistance.

Inspect the Outsole Design

Visually inspect the bottom of the shoe. Look for the defining features: a soft, pliable rubber sole and a dense pattern of small, multi-directional grooves. If the sole is hard, flat, or has only a few large, shallow lugs, it is not a true slip-resistant design.

Check for Explicit Labeling

Manufacturers will clearly advertise this feature. Read the product description and check the shoe's box or tongue for explicit terms like "slip-resistant" or "non-slip." While this is a good starting point, always try to verify it with the other physical indicators.

Consider Supporting Features

While not directly related to grip, other features indicate a shoe is built for hazardous workplaces. Look for water-resistant upper materials and a generally sturdy, durable construction, which are common in high-quality work footwear.

Common Pitfalls to Avoid

Understanding what doesn't work is as important as knowing what does. Many common beliefs and quick fixes fail to provide reliable protection and can create a false sense of security.

The Ineffectiveness of DIY "Hacks"

Applying temporary solutions like hairspray, sandpaper, or traction sprays is highly unreliable. These methods wear off quickly and are no substitute for a properly engineered outsole designed for consistent performance over time.

Not All Work Boots Are Slip-Resistant

Durability does not equal grip. A heavy, reinforced work boot may be "oil-resistant"—meaning its sole won't degrade from oil contact—but that does not mean it is slip-resistant on oily surfaces. These are two distinct features.

Why Standard Sneakers Don't Qualify

Everyday athletic shoes are built for other goals, like cushioning for running or court feel for basketball. Their soles are typically designed for grip on clean, dry surfaces and are ineffective and dangerous on wet or greasy floors.

Making the Right Choice for Your Goal

Selecting the right shoe depends entirely on the specific environment where you'll be wearing it.

- If your primary focus is safety in a restaurant or kitchen: Prioritize shoes with official ASTM certification and a tread pattern with small, circular grooves designed to channel away grease and water.

- If your primary focus is stability in a healthcare or service setting: Look for a certified slip-resistant sole combined with a comfortable, fluid-resistant upper that can be worn for long shifts.

- If you are simply looking to improve general traction on varied surfaces: Ensure any shoe you buy is explicitly labeled "slip-resistant" by the manufacturer and has a soft rubber sole with deep, multi-directional tread.

Ultimately, choosing a professionally designed and certified slip-resistant shoe is a direct investment in your personal safety.

Summary Table:

| Feature | Importance for Slip Resistance |

|---|---|

| Soft Rubber Sole | Creates high friction by conforming to floor surfaces. |

| Multi-Directional Tread Pattern | Channels liquids away to maximize floor contact. |

| ASTM F2913 Certification | Proves the shoe has passed rigorous safety testing. |

| Deep Grooves | Prevents hydroplaning by providing a strong 'bite' on the surface. |

Protect your team with certified, high-performance footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, safety-compliant footwear designed for demanding environments like kitchens, hospitals, and industrial sites. Contact us today to discuss your needs and receive a custom quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- How do men's work shoes ensure comfort during long work hours? An Engineer's Guide to All-Day Support

- What additional benefits do slip-resistant shoes offer besides safety? Boost Productivity & Professionalism

- What technologies are used in modern slip resistant shoes? Advanced Grip & Safety Explained

- What is the primary function of integrated physiological monitoring systems? Tracking ANS Health in Professional Shoes

- How do slip-resistant shoes benefit older individuals? Prevent Falls and Enhance Stability

- Do anti-slip shoes offer arch support? Yes, for safety and all-day comfort.

- Why is footwear important for dental professionals? Prevent Pain and Boost Your Career Longevity

- What industries commonly require slip resistant shoes? Essential Guide for Workplace Safety