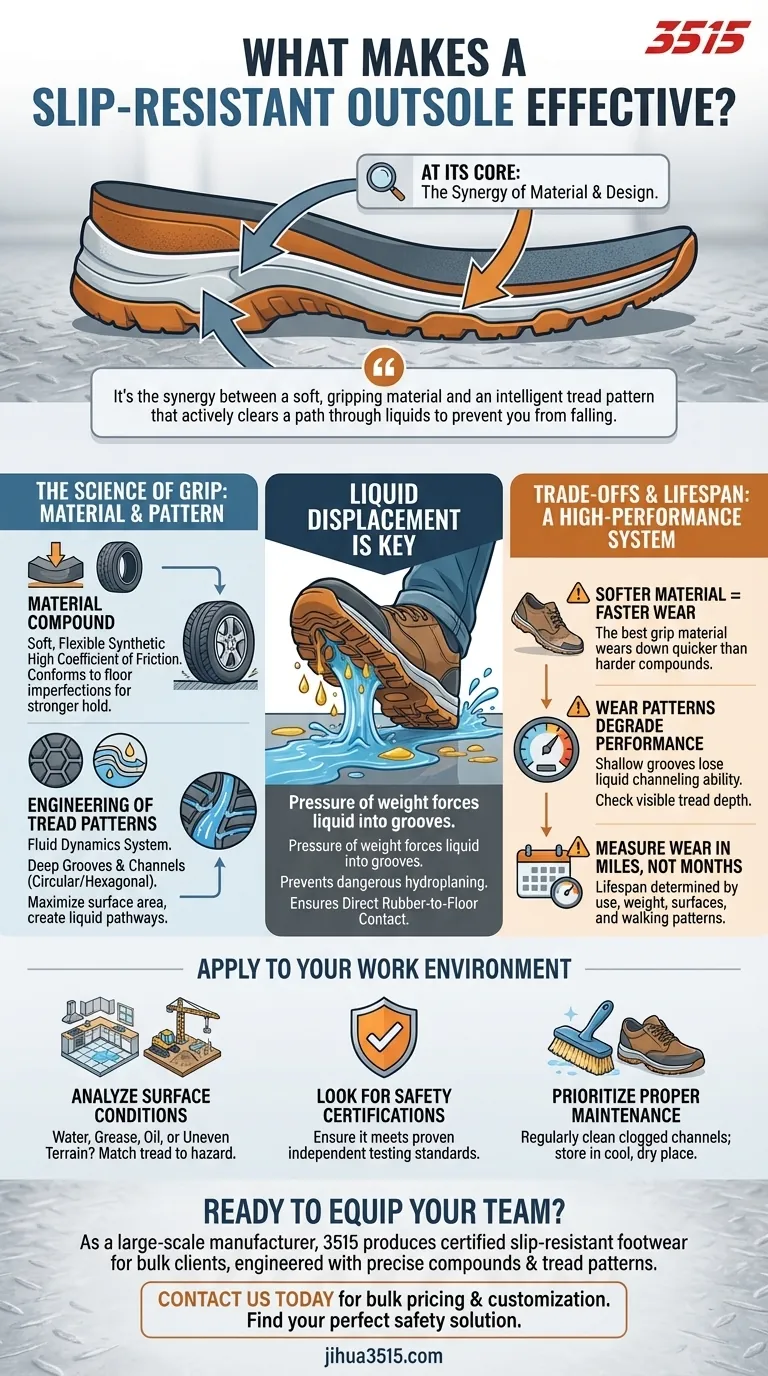

At its core, a slip-resistant outsole is effective because of a strategic combination of its material and its design. The outsole uses a soft, flexible rubber compound to maximize grip, while its specialized tread pattern is engineered with deep grooves to channel liquids like water and oil away, ensuring the rubber maintains direct contact with the floor.

The effectiveness of a slip-resistant shoe is not just about one feature, but a complete system. It's the synergy between a soft, gripping material and an intelligent tread pattern that actively clears a path through liquids to prevent you from falling.

The Science of Grip: How Outsoles Prevent Slips

To truly understand slip resistance, you must look at how the outsole's material and pattern work together to manage the forces at play on a slick surface. It's a problem of physics solved by clever engineering.

The Role of Material Compound

The primary material used is a soft, flexible synthetic rubber compound. Unlike the harder rubber on a standard shoe, this softer material has a higher coefficient of friction, which is the scientific measure of grip.

This flexibility allows the sole to conform to the microscopic imperfections of a floor surface, creating more contact area and a stronger hold, much like the soft tires on a race car.

The Engineering of Tread Patterns

The pattern of the tread is not for aesthetics; it's a fluid dynamics system. The design aims to maximize surface area for contact while incorporating a network of deep grooves and channels.

These patterns, often circular or hexagonal, create pathways for liquids to escape from underneath the shoe. Without these channels, liquid gets trapped, leading to a dangerous hydroplaning effect where you slide on a thin film of fluid.

Liquid Displacement is Key

The single most important function of the tread is liquid displacement. When you step on a wet or oily spot, the pressure of your weight forces the liquid into the deep grooves of the outsole.

This immediately clears the liquid from the flat, gripping surfaces of the tread, allowing the rubber to make solid, direct contact with the floor. This is what prevents the slip from ever happening.

Understanding the Trade-offs and Lifespan

An effective slip-resistant outsole is a high-performance piece of equipment, and like any such equipment, it comes with specific trade-offs and a limited effective lifespan. Understanding these is critical for maintaining safety.

Softer Material Means Faster Wear

The very property that makes the outsole grip so well—its softness—also makes it less durable than harder rubber compounds. The material that provides the best grip will inevitably wear down more quickly.

Wear Patterns Degrade Performance

Pay close attention to how the tread wears down. As the deep grooves become shallow from use, their ability to channel liquids is significantly reduced.

A shoe can look fine from the outside, but if the tread pattern is worn smooth, it has lost its primary safety feature and is no longer effectively slip-resistant.

Measure Wear in Miles, Not Months

The lifespan of your shoes is determined by your specific use. Factors like body weight, walking patterns, and the type of surfaces you walk on all contribute to wear.

It is far more accurate to judge a shoe's condition based on its visible tread depth and signs of wear rather than how many months you've owned it.

How to Apply This to Your Work Environment

Choosing the right shoe requires you to move beyond the label and evaluate its features against the specific hazards you face every day.

Analyze Your Surface Conditions

Consider the primary challenge in your workplace. Are you dealing with mostly water on a tile floor, grease and oil in a kitchen, or uneven terrain on a construction site? Each condition demands a slightly different tread design and material focus.

Look for Safety Certifications

Do not rely on marketing terms alone. Look for official safety certifications that confirm the shoe has passed independent testing for its slip-resistant properties. This ensures it meets a proven standard for safety.

Prioritize Proper Maintenance

The effectiveness of your shoes depends on their condition. Regularly clean the outsoles to remove dirt and debris that can clog the channels and reduce their ability to displace liquid. Store them in a cool, dry place to preserve the rubber compound.

Making the Right Choice for Your Goal

Use this knowledge to select footwear that is precisely matched to your safety needs and work demands.

- If your primary focus is maximum safety in wet or oily kitchens: Prioritize shoes with intricate, deep, and circular tread patterns designed specifically to channel away viscous liquids.

- If your primary focus is durability for long hours on your feet: Look for a certified slip-resistant shoe but also pay close attention to comfort features like cushioning, arch support, and overall build quality.

- If your primary focus is outdoor work with varied conditions: You may need a more rugged, hybrid tread that can handle water and mud while also providing grip on uneven surfaces.

By understanding the principles of material and design, you can make an informed decision that actively protects you from harm.

Summary Table:

| Feature | How It Works | Why It Matters |

|---|---|---|

| Material Compound | Soft, flexible rubber with a high coefficient of friction. | Conforms to floor surfaces for superior grip. |

| Tread Pattern | Deep grooves and channels (circular/hexagonal). | Actively displaces water, oil, and other liquids. |

| Liquid Displacement | Forces liquid into grooves under pressure. | Ensures direct rubber-to-floor contact to prevent hydroplaning. |

| Lifespan | Measured by tread wear, not time. | Performance degrades as grooves become shallow. |

Ready to equip your team with scientifically-engineered safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise material compounds and tread patterns detailed above to protect your workforce.

Contact us today for bulk pricing, customization options, and to find the perfect safety solution for your specific work environment.

Visual Guide

Related Products

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Durable Leather Moc Toe Work Boots for Wholesale & Custom Manufacturing

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- Why is maintenance important for work boots? Protect Your Investment and Safety

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- What are the potential consequences of wearing improperly designed work boots? Avoid Injury & Boost Safety

- What organization sets national standards for workplace safety in the U.S.? OSHA's Role Explained