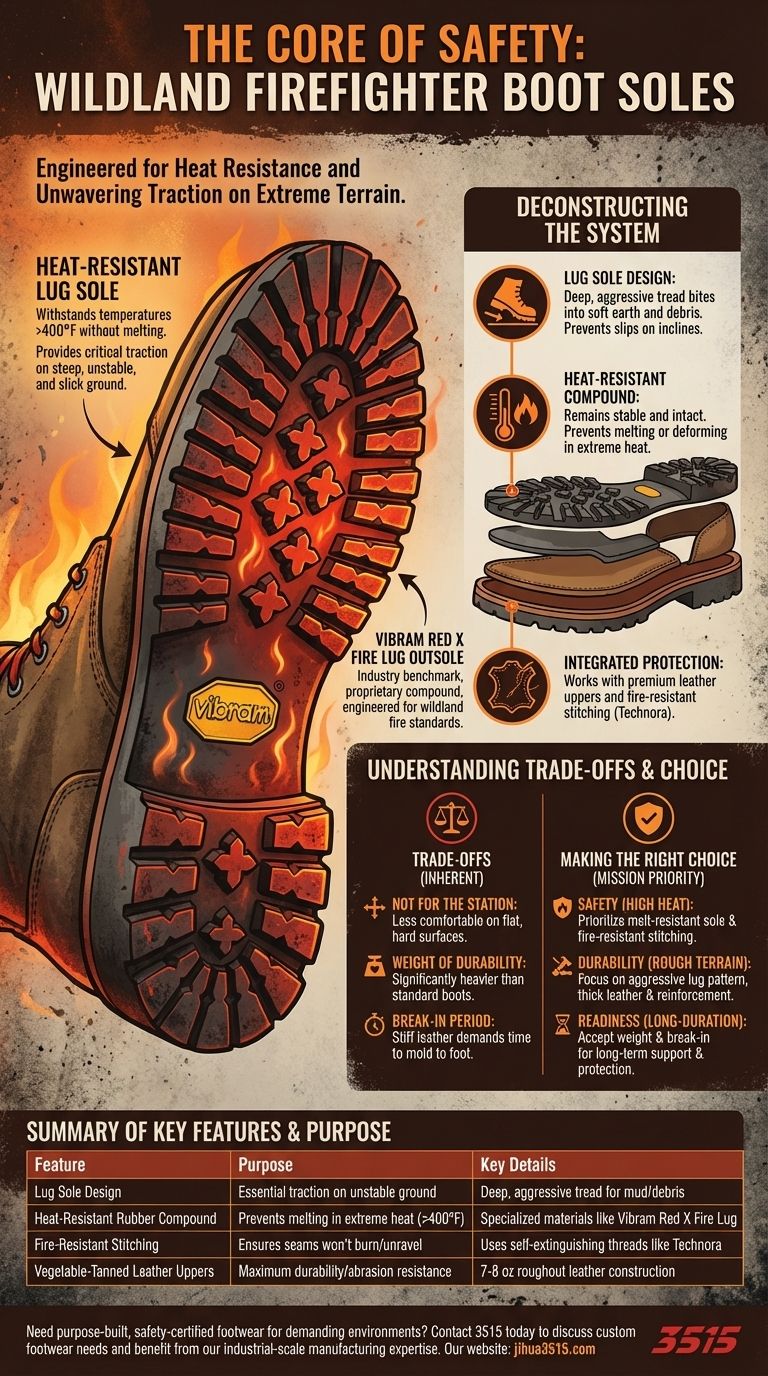

At their core, wildland firefighter boots use a heavy-duty lug sole made from a specialized, heat-resistant rubber compound. The most recognized example is the Vibram Red X Fire Lug outsole, which is engineered from a custom material designed to withstand temperatures exceeding 400°F without melting. This construction is non-negotiable, as it provides both critical heat protection and essential traction on the steep, uneven, and often slick terrain where wildfires occur.

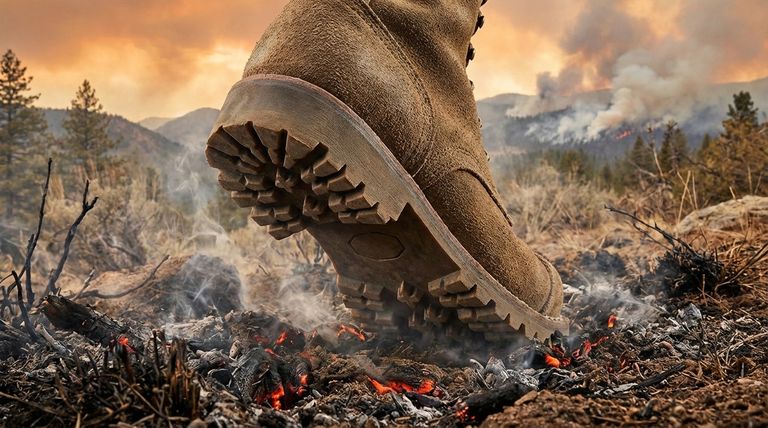

The sole of a wildland boot is not merely for walking; it is the foundational layer of a comprehensive safety system. Its design prioritizes heat resistance and unwavering grip above all else, because in a wildland fire, a failure of footing or material integrity can be catastrophic.

The Foundation of Safety: Deconstructing the Wildland Boot Sole

The sole is the boot's direct interface with the ground, which can be dangerously hot and unstable. Its design is a deliberate exercise in material science and functional engineering.

The Lug Sole Design

A lug sole is defined by its deep, aggressive tread pattern. These thick, widely spaced "lugs" are designed to bite into soft earth, mud, and loose debris, preventing slips on steep inclines and declines. This ensures stable footing, which is critical when carrying heavy gear over unpredictable ground.

The Critical Role of Heat Resistance

The primary distinguishing feature of a wildland boot sole is its ability to resist extreme heat. Standard boot soles would soften, melt, or delaminate when exposed to hot ground, embers, or ash.

Wildland soles are made from a proprietary compound that remains stable and intact at temperatures well over 400°F. This prevents the sole from deforming or, worse, melting away from the boot's upper, which would completely compromise the firefighter's safety.

A Prime Example: The Vibram Red X

The Vibram Red X Fire Lug is the industry benchmark for this technology. It is not just a standard rubber sole; it is a specific formulation engineered to meet the strict heat and performance standards required for wildland firefighting, ensuring both durability and firefighter safety.

Beyond the Sole: A System of Protection

While the sole is critical, it works in concert with other specialized components to create a fully protective boot. Understanding these elements reveals why these boots are so robust.

Premium Vegetable-Tanned Leather

The uppers are typically constructed from extremely thick 7-ounce to 8-ounce vegetable-tanned leather. This type of leather is much stiffer and more durable than the softer leathers used in casual or light-duty boots. Roughout leather (the flesh-side out) is often preferred because it resists and hides abrasions better than a smooth finish.

Fire-Resistant Stitching

The threads holding the boot together are just as important as the leather. Wildland boots use self-extinguishing, high-tensile threads like Technora. This synthetic fiber is thermally stable and water-resistant, ensuring that the boot's seams will not unravel or burn through when exposed to intense heat.

Reinforced Structural Support

To handle the stress of navigating rough terrain for long hours, these boots incorporate features like reinforced heel counters. This provides crucial ankle support and stability, reducing the risk of injury and fatigue during extended operations.

Understanding the Trade-offs

The highly specialized nature of wildland boots means they come with inherent trade-offs. They are designed for a singular, extreme purpose.

Built for the Wild, Not the Station

The same features that make these boots exceptional in the field—stiff leather and an aggressive, heavy sole—make them less comfortable for walking on flat, hard surfaces like concrete. They are a specific tool for a specific job.

The Weight of Durability

The robust construction, thick leather, and dense sole material result in a boot that is significantly heavier than a standard work boot. This weight is a direct trade-off for the unparalleled level of protection and durability required.

A Necessary Break-in Period

The stiff, durable vegetable-tanned leather demands a significant break-in period. This is a well-known characteristic and a necessary process to ensure the boot eventually molds to the wearer's foot for long-term use.

Making the Right Choice for Your Mission

Choosing and understanding this gear is about prioritizing safety in an environment with no margin for error. The design principles are clear and purpose-driven.

- If your primary focus is safety in high heat: The melt-resistant lug sole and fire-resistant stitching are the most critical, non-negotiable features.

- If your primary focus is durability on rough terrain: The combination of an aggressive lug pattern, thick vegetable-tanned leather, and reinforced construction is paramount.

- If your primary focus is long-duration operational readiness: You must accept the trade-offs of weight and a break-in period to gain the support and protection needed for extended missions.

Ultimately, every component of a wildland boot is engineered with a single purpose: to provide an unwavering foundation of safety in one of the world's most demanding environments.

Summary Table:

| Feature | Purpose | Key Details |

|---|---|---|

| Lug Sole Design | Provides essential traction on unstable ground | Deep, aggressive tread pattern to bite into mud and debris |

| Heat-Resistant Rubber Compound | Prevents melting in extreme heat (>400°F) | Specialized materials like Vibram Red X Fire Lug |

| Fire-Resistant Stitching | Ensures seams won't burn or unravel | Uses self-extinguishing threads like Technora |

| Vegetable-Tanned Leather Uppers | Offers maximum durability and abrasion resistance | Typically 7-8 ounce roughout leather construction |

Need purpose-built, safety-certified footwear for demanding environments?

As a large-scale manufacturer, 3515 produces a comprehensive range of heavy-duty footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized boots, including those engineered for extreme heat and rugged terrain, ensuring the highest standards of durability and protection.

Contact 3515 today to discuss your custom footwear needs and benefit from our industrial-scale manufacturing expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are some common safety risks associated with inadequate work boots? Protect Your Workforce from the Ground Up

- How do leather and synthetic materials compare in work boots? Choose the Right Material for Your Job

- How can heavy duty boots be weatherproofed? A Step-by-Step Guide to Lasting Protection

- What are the key characteristics of packer boots? The Ultimate Hybrid for Ranch & Riding

- How have synthetic materials influenced the design of Western boots? Boost Performance & Safety

- Why is hydraulic oil resistance necessary for Work Boots? Essential Safety for Agricultural Heavy-Duty Maintenance

- Why is it important to keep work boots dry? Protect Your Feet and Extend Boot Life

- What are the main benefits of composite toe work boots? Lighter, Safer, and More Comfortable