Properly weatherproofing heavy-duty boots is a systematic process that goes beyond simply applying a product. It requires thoroughly cleaning the boots to remove any dirt that can obstruct the treatment, allowing them to dry completely, and then applying a suitable weatherproofing agent evenly across all surfaces, paying special attention to seams and joints.

The goal of weatherproofing is not to coat the boot in a shell, but to condition the material—whether leather or synthetic—to repel water naturally. This is achieved through a disciplined process of preparation, application, and curing that protects both the boot and your feet.

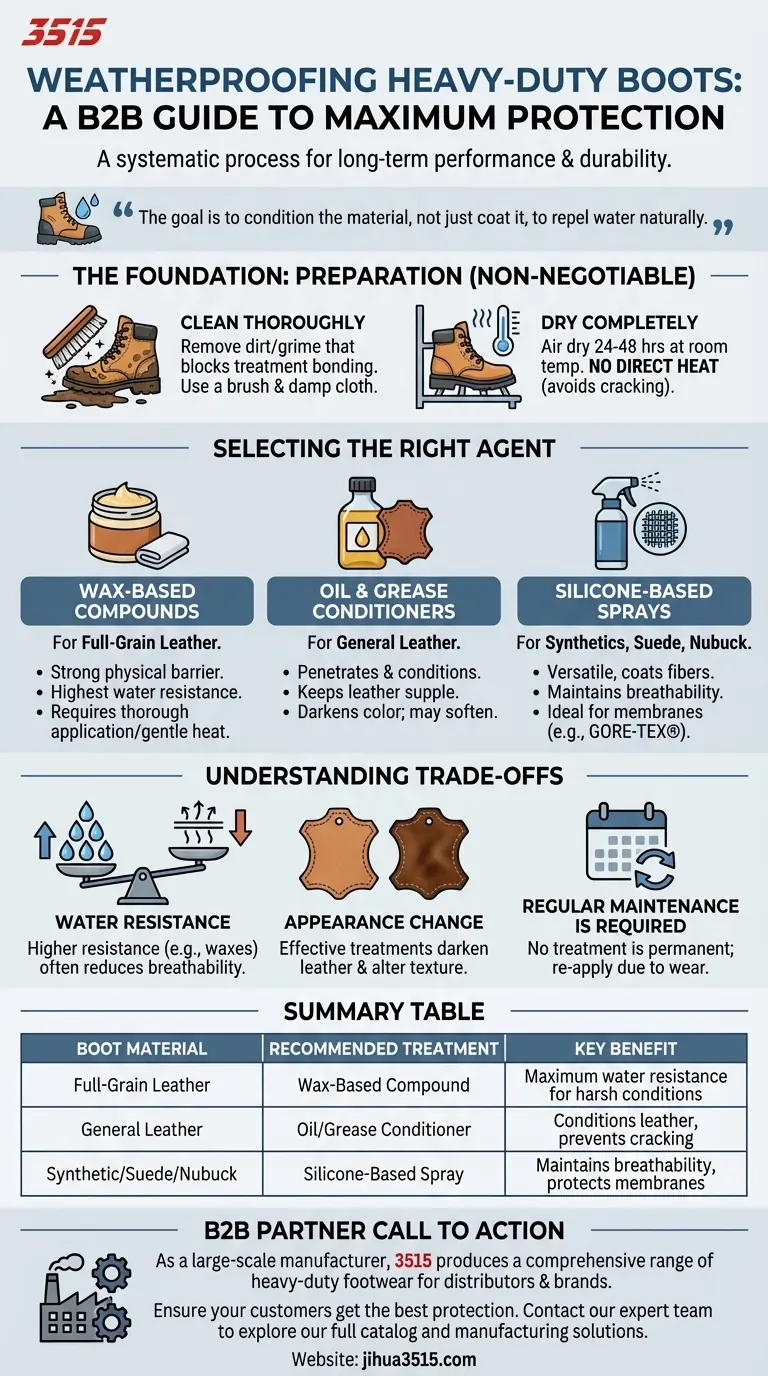

The Foundation: Preparing Your Boots for Treatment

Before you apply any product, the boot's surface must be in a receptive state. Skipping this foundational stage is the most common point of failure in any weatherproofing effort.

Why Cleaning is Non-Negotiable

Dirt, mud, and grime are more than just cosmetic issues. They hold moisture against the boot's material and physically block weatherproofing agents from bonding with the leather or fabric fibers.

A stiff brush and a damp cloth are your primary tools. For stubborn dirt, a specialized boot cleaner or a simple mixture of mild soap and water is effective.

The Critical Drying Phase

Applying a treatment to damp boots is a critical error. This traps residual moisture inside the material, which can lead to premature rot, material degradation, and a poor bond for the waterproofing agent.

Always allow boots to air dry completely at room temperature for at least 24-48 hours. Never use direct heat from a fire, radiator, or hairdryer, as this can crack leather and damage adhesives.

Selecting the Right Weatherproofing Agent

The product you choose must be compatible with your boot's material. There are three primary categories of treatments, each with a distinct purpose.

Wax-Based Compounds

These products create a robust physical barrier on the surface of the material. They are exceptionally effective for full-grain leather boots used in consistently wet or snowy conditions.

Waxes offer the highest degree of water resistance but require thorough application, often with gentle heat to help the wax penetrate the leather's pores.

Oil and Grease Conditioners

Products like mink oil or other boot greases penetrate the leather, conditioning the fibers and providing a high degree of water resistance.

They are excellent for keeping leather supple and preventing it from drying out and cracking. However, they will almost always darken the leather's color and can sometimes soften it more than desired.

Silicone-Based Sprays

Sprays are the most versatile option, suitable for synthetic fabrics, suede, and nubuck. They coat the individual fibers with a water-repellent layer without clogging the material's pores.

This makes them the ideal choice for boots that feature a breathable, waterproof membrane like GORE-TEX, as they won't compromise its function.

Understanding the Trade-offs

Effective weatherproofing involves balancing competing priorities. Understanding these trade-offs allows you to choose the best method for your specific needs.

Water Resistance vs. Breathability

The most effective waterproofing treatments, like heavy waxes, create an impermeable barrier. This is excellent for keeping water out, but it also significantly reduces the material's breathability, which can lead to sweaty, uncomfortable feet in warmer conditions.

Altering Appearance and Texture

Almost any effective treatment, particularly oils and waxes, will change the appearance of your boots. Leather will typically darken, and its texture may become smoother or more waxy to the touch. Always test a product on a small, inconspicuous area first.

The Myth of Permanent Waterproofing

No treatment is permanent. Abrasion from walking, exposure to UV light, and the simple passage of time will break down any weatherproofing agent. Regular maintenance is not optional; it is a required part of owning high-quality boots.

Matching the Method to Your Mission

Your specific use case should dictate your approach. Follow these guidelines to make the right choice.

- If your primary focus is maximum water repellency in harsh, wet conditions: Opt for a heavy-duty, wax-based sealant on full-grain leather boots after a meticulous cleaning.

- If your primary focus is maintaining breathability for varied conditions: Use a silicone-based spray, especially on boots with synthetic panels or membranes, and re-apply it more frequently.

- If your primary focus is conditioning and preserving heritage leather boots: Use a quality oil or grease conditioner, accepting that it will darken the leather as part of the preservation process.

Ultimately, a consistent care regimen is the definitive factor in the long-term performance and protection of your boots.

Summary Table:

| Boot Material | Recommended Treatment | Key Benefit |

|---|---|---|

| Full-Grain Leather | Wax-Based Compound | Maximum water resistance for harsh conditions |

| General Leather | Oil/Grease Conditioner | Conditions leather, prevents cracking |

| Synthetic/Suede/Nubuck | Silicone-Based Spray | Maintains breathability, protects membranes |

As a large-scale manufacturer, 3515 produces a comprehensive range of heavy-duty footwear for distributors, brand owners, and bulk clients.

Ensure your customers get the best protection from the start. Our production capabilities encompass all types of durable, weather-ready boots built for performance. Let's discuss how we can meet your specific needs.

Contact our expert team today to explore our full catalog and manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do EH-rated work boots protect against electrical hazards? Insulate Against Shock with Certified Safety

- How does the height of PVC work boots affect protection? A Guide to Choosing the Right Boot for Your Job

- What are the differences between Lace Up, Zip Sided, and Pull On work boots? Find Your Perfect Fit for Safety & Convenience

- Why is rotating two pairs of work boots recommended? Double Boot Life & Boost Foot Health

- What are the advantages of ankle-high lace-up boots? Superior Support & Style for Work & Office

- What are the temperature ratings and recommended uses for 1,000g insulated boots? Stay Warm in Extreme Cold

- How do engineer boots function compared to other types of boots? A Guide to Their Unique Design & Purpose

- How should lace-up boots be properly worn? Master the Fit for All-Day Comfort and Support