To ensure reliable traction, cold-weather boots depend on specific outsole features designed to grip unstable surfaces. The most critical elements are deep, aggressive lugs and a textured tread pattern, which work together to bite into snow and channel away slush for a stable footing.

The key to preventing slips is not a single feature, but the boot's entire outsole system. True cold-weather traction comes from a strategic combination of a flexible rubber compound, a deep tread pattern, and multi-directional lugs that adapt to unpredictable winter surfaces.

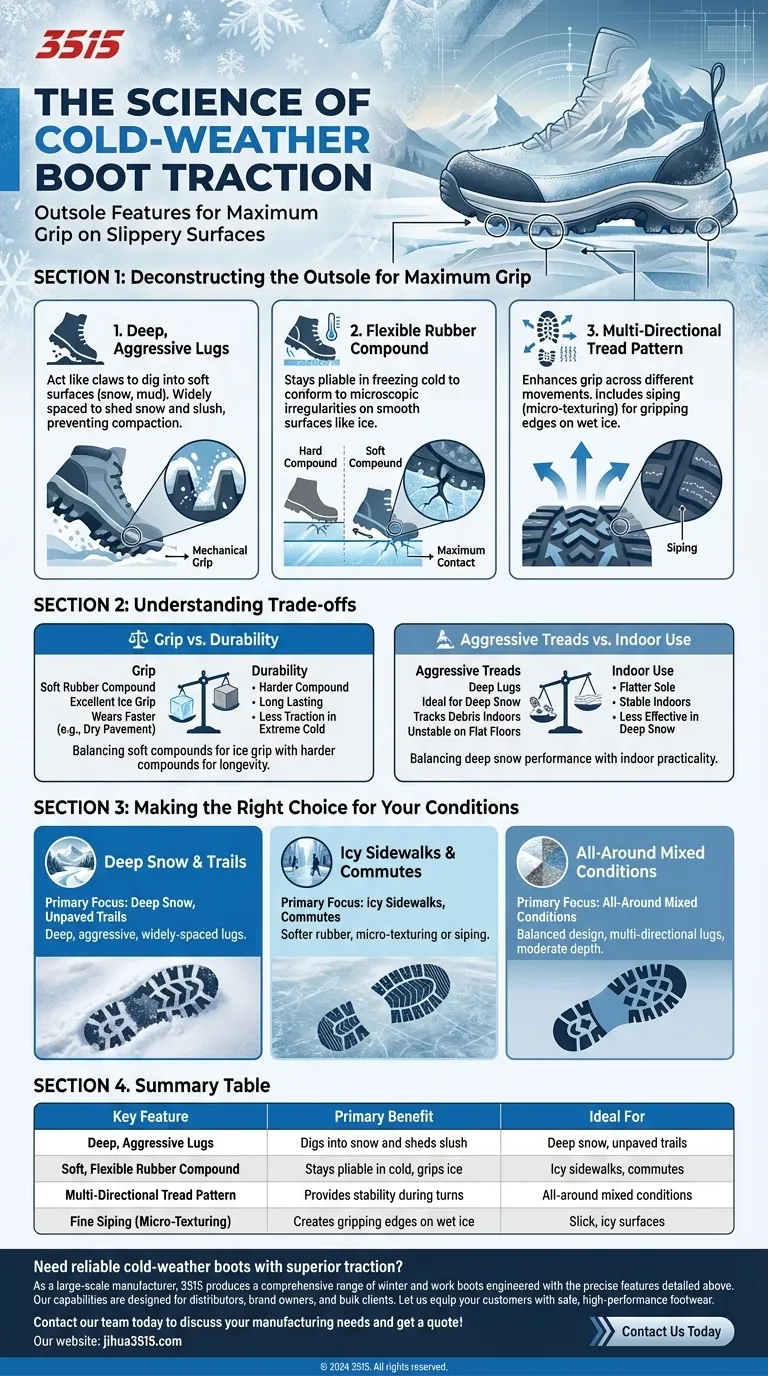

Deconstructing the Outsole for Maximum Grip

The bottom of your boot, the outsole, is the only part that touches the ground. Its design is the single most important factor for determining your stability on ice and snow. We can break down its effectiveness into three core components.

The Role of Deep Lugs

Lugs are the deep protrusions on the outsole. Their primary job is to act like claws, digging into soft or loose surfaces like snow and mud.

Deeper and more widely-spaced lugs provide a powerful mechanical grip, preventing the sole from skimming over the top of the snow. This design also helps shed snow and slush, preventing it from compacting and creating a smooth, slippery surface on the bottom of your boot.

Why Material Compound Matters

The specific rubber or synthetic compound used for the outsole is crucial. Materials behave differently as temperatures drop.

A quality winter boot uses a softer rubber compound that remains flexible even in freezing cold. This pliability allows the sole to make maximum contact with the ground, conforming to microscopic irregularities to grip smooth surfaces like ice. Harder compounds can become rigid and slick in the cold.

The Importance of Tread Pattern

The arrangement and texture of the lugs create the overall tread pattern. A good pattern enhances grip across different movements and conditions.

Look for multi-directional lugs, which provide reliable traction whether you are walking uphill, downhill, or making a sudden turn. Some outsoles also feature very fine, slit-like texturing (known as siping) that creates thousands of tiny gripping edges, significantly improving traction on wet ice.

Understanding the Trade-offs

No single boot design is perfect for every possible winter scenario. Choosing the right features often involves balancing competing priorities.

Grip vs. Durability

There is often a direct trade-off between ice grip and long-term durability.

Softer rubber compounds that excel on ice will wear down more quickly, especially if used frequently on dry pavement. Harder, more durable compounds will last longer but offer less effective traction in very cold or icy conditions.

Aggressive Treads vs. Indoor Use

An outsole with deep, aggressive lugs is ideal for deep snow but can be impractical for mixed use.

These treads can feel unstable or clumsy on hard, flat indoor surfaces like tile or concrete. They also tend to track significant amounts of snow, mud, and debris indoors, making them less suitable for transitioning frequently between outside and inside.

Making the Right Choice for Your Conditions

Evaluate your most common winter environment to select the features that will serve you best.

- If your primary focus is deep snow and unpaved trails: Prioritize boots with deep, widely-spaced, and aggressive lugs for maximum mechanical grip.

- If your primary focus is icy sidewalks and commutes: Look for a softer rubber outsole, ideally with micro-texturing or siping for enhanced grip on smooth ice.

- If your primary focus is all-around mixed conditions: Seek a balanced design with multi-directional lugs of moderate depth made from a quality cold-weather rubber compound.

Understanding the science of the sole empowers you to walk with confidence, no matter the weather.

Summary Table:

| Key Feature | Primary Benefit | Ideal For |

|---|---|---|

| Deep, Aggressive Lugs | Digs into snow and sheds slush | Deep snow, unpaved trails |

| Soft, Flexible Rubber Compound | Stays pliable in cold, grips ice | Icy sidewalks, commutes |

| Multi-Directional Tread Pattern | Provides stability during turns and varied movements | All-around mixed conditions |

| Fine Siping (Micro-Texturing) | Creates thousands of gripping edges on wet ice | Slick, icy surfaces |

Need reliable cold-weather boots with superior traction? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of winter boots and work boots, engineered with the precise outsole features—like deep lugs and cold-flexible rubber—detailed in this article. Let us help you equip your customers with safe, high-performance footwear. Contact our team today to discuss your manufacturing needs and get a quote!

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How long do combat boots typically last with proper care? Maximize Durability from 1 to 5+ Years

- What features are considered in the design of military boot soles? The 4 Pillars of Mission-Ready Footwear

- What are some common upper materials used in military boots? Choose the Right Material for Your Mission

- Why is safety and comfort important in military boots? The Key to Soldier Endurance and Mission Success

- What are the different styles of combat boots available? A Guide to Performance vs. Fashion

- How should military boots be broken in before hiking? A Step-by-Step Guide to Prevent Blisters

- Why is it important to clean and maintain military boots? Preserve Function & Longevity

- How did combat boots evolve historically? From Roman Sandals to Modern Tactical Gear