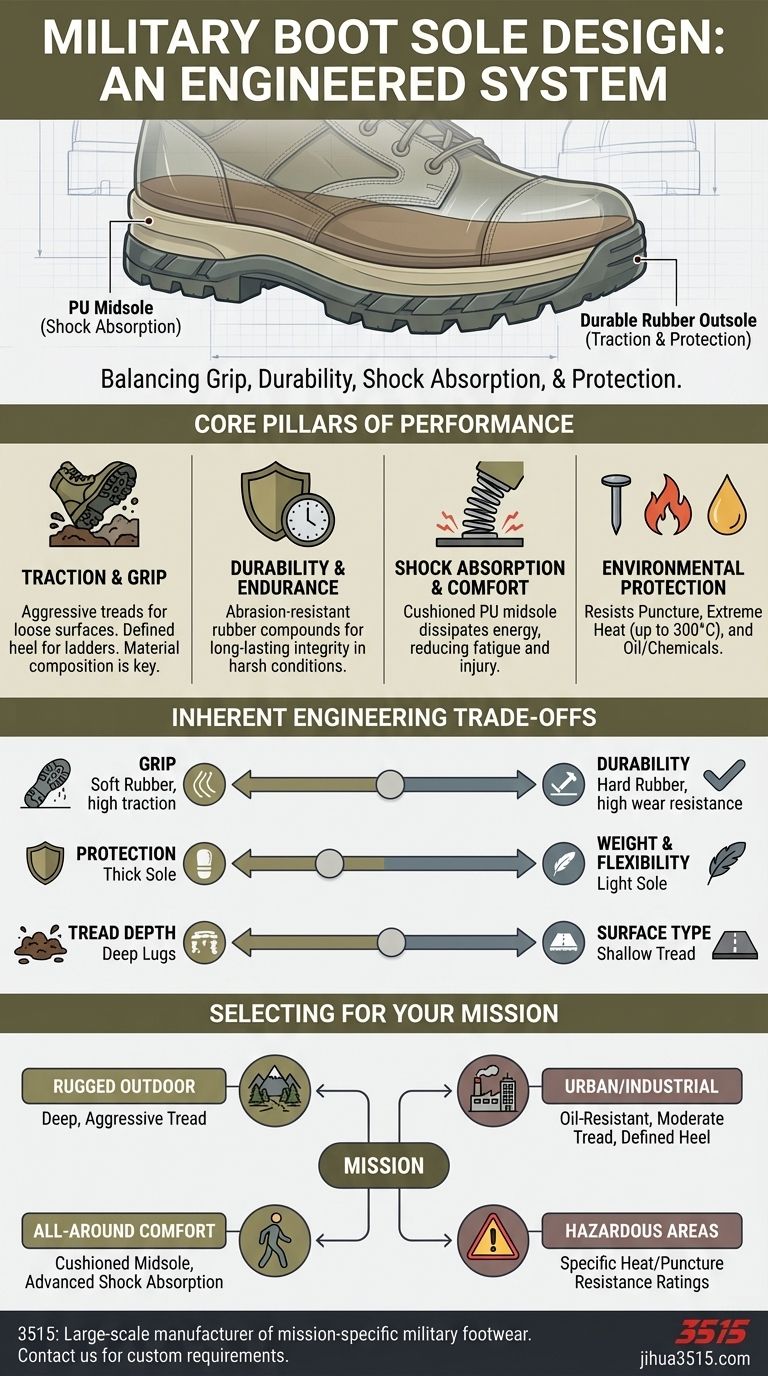

At its core, a military boot sole is an engineered system designed to balance four critical functions: exceptional grip, long-term durability, crucial shock absorption, and protection from environmental hazards. This is achieved through a combination of advanced materials like polyurethane (PU) and durable rubber, specialized tread patterns, and structural technologies built directly into the sole's construction.

The design of a military boot sole is a mission-specific engineering challenge. It's not about finding a single "best" design, but about creating an optimal balance between grip, protection, and endurance for a specific operational environment.

Core Pillars of Sole Performance

The primary function of any boot sole is to interface between the user and the ground. In a military context, this interface must be reliable under the most demanding conditions.

Achieving Superior Traction and Grip

A soldier's stability depends entirely on the sole's grip. The design focuses on two key elements: tread pattern and material composition.

Aggressive, deep treads are engineered to bite into soft or loose surfaces like mud, sand, and gravel, providing stable footing.

Conversely, a sole intended for flat surfaces like ship decks or concrete floors may have shallower treads to maximize surface contact. A defined heel is often included to help catch ladder rungs or lock into position on gantries.

Ensuring Durability and Endurance

Military boot soles are made from highly durable rubber compounds designed to resist abrasion and wear.

The sole must maintain its structural integrity and tread pattern over hundreds of miles of use in harsh conditions to ensure performance does not degrade over the life of the boot.

Maximizing Shock Absorption and Comfort

Long marches and high-impact movements generate significant force on the body. A key design feature is shock absorption, often managed by a cushioned polyurethane (PU) midsole.

This layer compresses upon impact, dissipating energy that would otherwise travel up the legs and spine, thereby reducing fatigue and preventing injury. Some designs incorporate "Frame Technology" to provide additional stability and support.

Specialized Environmental Protections

Beyond fundamental performance, military boot soles are often designed to protect the user from specific environmental threats.

Resistance to Puncture

The sole must be thick and robust enough to prevent penetration by sharp objects like nails, glass, or rock shards. This provides a critical layer of protection against battlefield debris and environmental hazards.

Resistance to Extreme Temperatures

For personnel working in certain environments, such as on hot asphalt or near engine components, heat resistance is a vital feature.

Specialized soles are rated to withstand extreme temperatures, with some offering protection up to 572ºF (300ºC) to prevent delamination or melting.

Resistance to Oil and Chemicals

In industrial settings or during vehicle maintenance, exposure to oil and other chemicals can degrade rubber and create dangerously slick surfaces.

Oil-resistant soles use specific rubber compounds that do not break down upon contact with petrochemicals, ensuring both the longevity of the boot and the safety of the user.

Understanding the Inherent Trade-offs

No single sole design can excel in every category. Every feature represents a deliberate engineering trade-off.

Grip vs. Durability

Softer rubber compounds provide outstanding grip, especially on smooth, wet surfaces. However, they tend to wear down much faster. Harder compounds offer excellent durability but can sacrifice some measure of traction.

Protection vs. Weight and Flexibility

A thick, puncture-resistant sole offers maximum protection but adds significant weight and stiffness. This can reduce mobility and increase fatigue over long distances. A lighter, more flexible sole is better for agility but offers less protection.

Tread Depth vs. Surface Type

Deep lugs are essential for mud but can create pressure points and wear unevenly on hard, flat surfaces. A shallower tread is ideal for urban environments but will quickly become ineffective in off-road conditions.

Selecting a Sole for Your Mission

Choosing a boot requires matching the sole's design characteristics to your most likely operational environment.

- If your primary focus is rugged, outdoor terrain: Prioritize a sole with deep, aggressive treads for maximum grip on mud and loose ground.

- If your primary focus is urban or industrial environments: Look for oil-resistant soles with a moderate tread depth and a defined heel for stability on ladders and flat surfaces.

- If your primary focus is all-around comfort and reduced fatigue: Emphasize designs with cushioned midsoles and advanced shock absorption technology.

- If your primary focus is safety in hazardous areas: Ensure the sole meets the specific heat or puncture resistance ratings required for your role.

Ultimately, the most effective sole is the one engineered specifically for the challenges you will face.

Summary Table:

| Feature | Key Design Elements | Primary Benefit |

|---|---|---|

| Traction & Grip | Aggressive tread patterns, specialized rubber compounds | Stability on loose or slippery surfaces |

| Durability | High-abrasion rubber, reinforced construction | Long-lasting performance in harsh conditions |

| Shock Absorption | Cushioned PU midsoles, frame technology | Reduces fatigue and injury risk from impact |

| Protection | Puncture-resistant layers, heat/oil-resistant materials | Safeguards against environmental hazards |

Need mission-specific military boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of military boots and soles, engineered to meet the exact demands of your operational environment.

Contact 3515 today to discuss your custom boot requirements and get a quote.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- How do combat boots ensure foot protection? The Science Behind Maximum Safety

- What are the main compliance considerations for military boot procurement? Navigating TAA & Domestic Sourcing

- How should military boots be dried after cleaning? The Key to Preserving Your Gear's Integrity

- What is Camouflage Techno Fabric used for? Performance Gear for Demanding Environments

- How do military boots differ from tactical boots? Choose the Right Boot for Your Mission

- Where are high-quality Desert Boots traditionally made? Crafted in England with Premium Materials

- What are the specifications of Navy boots? A Guide to US Navy-Approved Footwear

- How do military boots enhance comfort for everyday wear? Experience Superior All-Day Support