The most common materials used for the uppers of military boots are full-grain leather, suede, and high-performance synthetic fabrics like nylon. Each material is chosen for a specific balance of durability, weight, breathability, and resistance to the elements. These core materials are often combined or integrated with specialized waterproof membranes to enhance performance in specific environments.

The choice of a military boot's upper material is not about finding the "best" one, but about understanding the fundamental trade-off. You are always balancing the relationship between durability, environmental protection, weight, and breathability to match the demands of a specific mission.

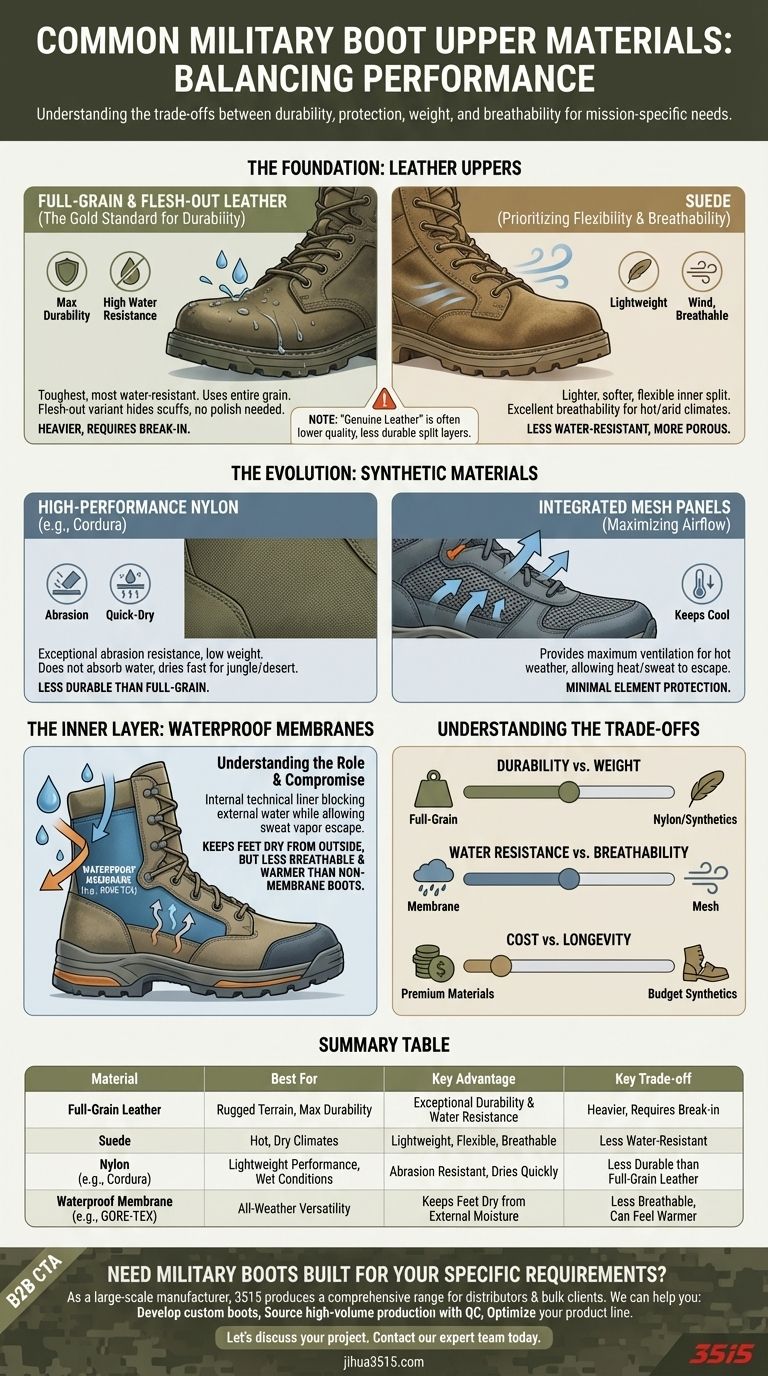

The Foundation: Leather Uppers

Leather has long been the standard for military footwear due to its exceptional durability and ability to mold to the wearer's foot over time. However, not all leather is created equal.

Full-Grain and Flesh-Out Leather: The Gold Standard for Durability

Full-grain leather is the toughest and most water-resistant type of leather available. It uses the entire grain of the hide, making it incredibly rugged and capable of withstanding extreme abuse.

A common variant in military use is flesh-out leather, which is full-grain leather flipped to expose the rougher, textured side. This surface is less prone to showing scuffs and does not need to be polished, making it ideal for field use.

Suede: Prioritizing Flexibility and Breathability

Suede is a lighter, softer, and more flexible type of leather made from the inner split of the hide. Its fibrous nature provides excellent breathability, making it a popular choice for boots intended for hotter, more arid climates.

While comfortable, suede is more porous and less water-resistant than full-grain leather, requiring more maintenance to protect it from stains and moisture.

A Note on "Genuine Leather"

Be aware that the term "genuine leather" can be misleading. While it is real leather, it often refers to a lower-quality grade made from the layers of the hide that remain after the top grain is split off. It is less durable and does not possess the longevity of full-grain leather.

The Evolution: Synthetic Materials

Modern advancements have led to synthetic materials that offer significant advantages in weight and specialized performance, often used in combination with leather.

High-Performance Nylon Fabrics (Cordura)

Fabrics like Cordura are a type of high-denier nylon prized for their exceptional abrasion resistance and low weight. These textiles are frequently used to form large panels on the boot's upper.

Nylon fabrics do not absorb water and dry very quickly, making them a superior choice for boots designed for jungle, desert, or amphibious operations where weight and breathability are critical.

Integrated Mesh Panels: Maximizing Airflow

For boots designed specifically for hot weather, engineered mesh panels are integrated into the upper. These panels provide maximum ventilation, allowing heat and sweat to escape efficiently to keep the foot cool and dry.

The Inner Layer: Waterproof Membranes

Many modern boots incorporate a waterproof membrane, which functions as an internal liner between the outer upper material and the foot.

Understanding the Role of a Membrane

A waterproof membrane is not the exterior fabric you see and touch. It is a technical layer, like a bootie, built into the boot's construction.

The most well-known brand is GORE-TEX, but other technologies like Sympatex exist. Their primary job is to block external water from entering the boot while still allowing water vapor (sweat) to escape.

The Breathability Compromise

This technology creates a waterproof-breathable system. While it keeps your feet dry from rain or puddles, no membrane is as breathable as a boot without one, such as a boot with simple mesh panels.

Understanding the Trade-offs

Choosing the right boot means understanding the inherent compromises in its design. No single boot can excel in every category.

Durability vs. Weight

A boot made entirely of full-grain leather will offer maximum durability but will be significantly heavier. A boot made primarily of nylon and synthetic materials will be far lighter but may not withstand the same level of long-term punishment.

Water Resistance vs. Breathability

A boot with a GORE-TEX membrane will keep your feet dry from external water but can feel warm and trap sweat in hot, high-exertion scenarios. A highly breathable desert boot with mesh panels will feel cool but will offer almost no protection from water.

Cost vs. Longevity

Premium materials like full-grain leather and brand-name membranes increase the cost of a boot. However, this initial investment often results in a boot that lasts significantly longer than less expensive synthetic alternatives.

Selecting the Right Upper for Your Mission

Your choice should be dictated entirely by the environment and task at hand.

- If your primary focus is maximum durability and ankle support for rugged terrain: Choose a boot constructed primarily from full-grain or flesh-out leather.

- If your primary focus is lightweight performance in hot, dry climates: Look for an upper made from suede and Cordura nylon panels, ideally with mesh for ventilation.

- If your primary focus is all-weather versatility and keeping feet dry from external moisture: Select a combination leather-and-nylon upper that includes a GORE-TEX waterproof membrane.

- If your primary focus is a budget-friendly, low-maintenance option for general use: A boot with synthetic leather uppers can be a practical choice, accepting the trade-off in durability.

Ultimately, understanding these materials empowers you to select gear that is a true asset, not a liability, for your specific objectives.

Summary Table:

| Material | Best For | Key Advantage | Key Trade-off |

|---|---|---|---|

| Full-Grain Leather | Rugged Terrain, Max Durability | Exceptional Durability & Water Resistance | Heavier, Requires Break-in |

| Suede | Hot, Dry Climates | Lightweight, Flexible, Breathable | Less Water-Resistant |

| Nylon (e.g., Cordura) | Lightweight Performance, Wet Conditions | Abrasion Resistant, Dries Quickly | Less Durable than Full-Grain Leather |

| Waterproof Membrane (e.g., GORE-TEX) | All-Weather Versatility | Keeps Feet Dry from External Moisture | Less Breathable, Can Feel Warmer |

Need Military Boots Built for Your Specific Requirements?

As a large-scale manufacturer, 3515 produces a comprehensive range of military and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, from durable full-grain leather designs to lightweight synthetic models with advanced waterproof membranes.

We can help you:

- Develop custom boots tailored to your target environment and performance needs.

- Source reliable, high-volume production with consistent quality control.

- Optimize your product line with the right material combinations for durability, cost, and performance.

Let's discuss your project. Contact our expert team today for a consultation.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

People Also Ask

- Why is breathability important in military boots? Prevent Blisters & Infections for Peak Performance

- What should you check for when walking in new military boots? Achieve the Perfect Fit for Your Mission

- Why is high ankle support important in cold-weather boots? Essential for Warmth and Stability

- What durable materials are commonly used in cold-weather boots? Leather vs. Synthetics Explained

- Can jungle boots be used in temperate climates? Maximize Comfort in Warm, Wet Conditions

- What features ensure good traction in military boots? The Ultimate Guide to Stable Footwear

- What traction features help cold-weather boots perform well on slippery surfaces? Master Winter Grip with the Right Outsole

- What are the key features of insulated boots designed for cold weather? A Guide to Warmth, Dryness & Safety