While cowboy boot making shares many tools with general shoemaking, the craft relies on a few highly specialized instruments to master the boot's unique anatomy. The most critical of these are crimp boards for pre-shaping the instep and shank-lasting pincers for securing the boot's structural foundation during the lasting process.

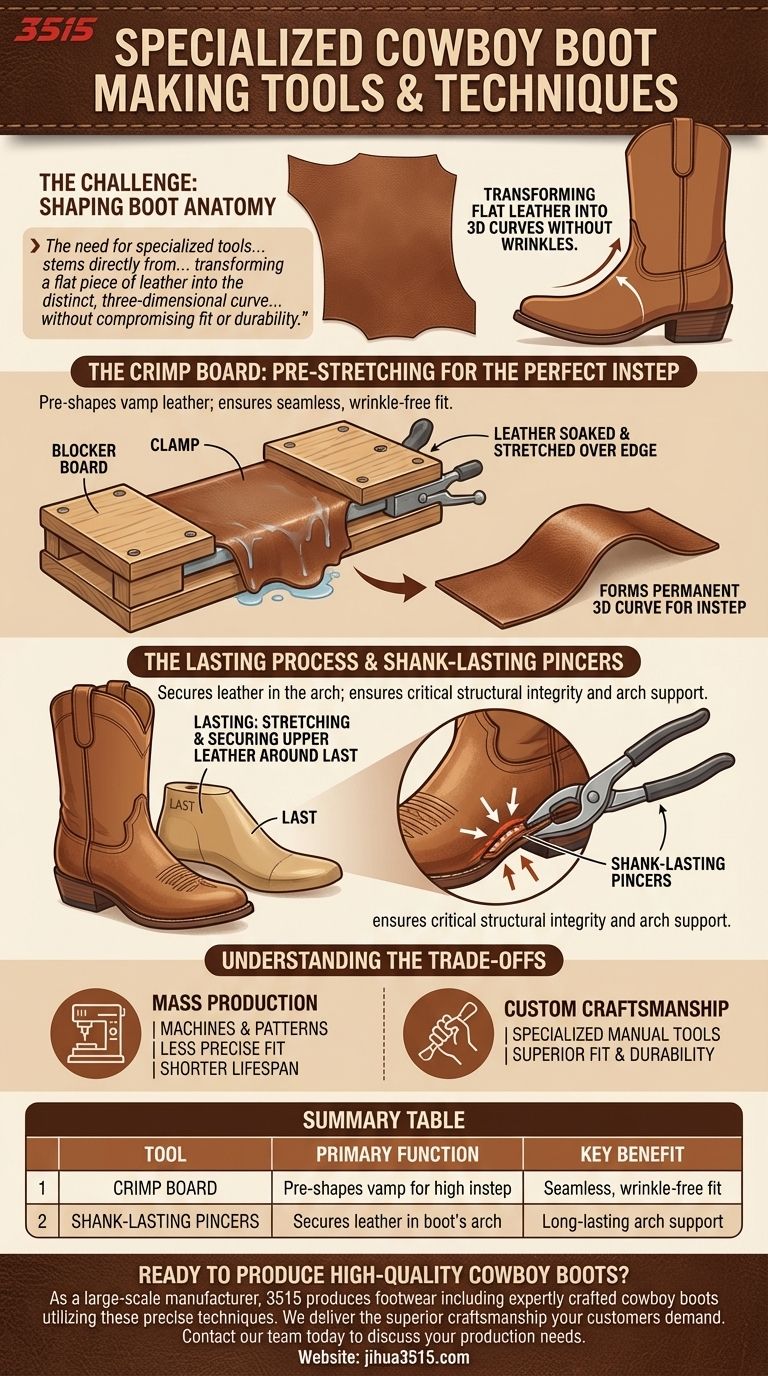

The need for specialized tools in cowboy boot making stems directly from a single challenge: transforming a flat piece of leather into the distinct, three-dimensional curve of a boot's high instep and shaft without compromising fit or durability.

The Challenge: Shaping a Boot's Unique Anatomy

Unlike a low-cut shoe, a cowboy boot has a tall shaft and a pronounced instep. Forcing a single piece of leather to conform to this complex shape during the lasting stage would create unsightly wrinkles and structural weakness. Specialized tools were developed to solve this problem before the final assembly even begins.

The Crimp Board: Pre-Stretching for the Perfect Instep

A crimp board, also known as a blocker board, is a simple but essential device. It consists of two wooden boards used to shape the vamp—the piece of leather covering the top of the foot.

The boot maker soaks the vamp leather in water to make it pliable. It is then stretched over the edge of one board and clamped tightly by the second, often using crimp screws to apply immense and even pressure.

As the leather dries over several days, it forms a permanent, three-dimensional curve that perfectly matches the high instep of the boot last. This pre-shaping is the secret to the clean, seamless look of a quality boot.

The Lasting Process: From Flat Leather to Foot Form

After crimping, the shaped vamp is ready for lasting. This is the core process of stretching and securing the boot's upper leather around a last, which is a mold shaped like a human foot.

This is where the boot truly takes its final form, ensuring a snug and accurate fit. The tension applied during lasting is critical for the boot's longevity.

Shank-Lasting Pincers: Securing the Boot's Foundation

While standard pincers are used for much of the lasting process, the tight curve of the boot's arch, or shank, requires a specialized tool.

Shank-lasting pincers have a unique shape designed to grip, pull, and tack the leather securely in this difficult-to-reach area. Proper lasting in the shank is fundamental to the boot's structure, providing the wearer with necessary arch support.

Understanding the Trade-offs

The use of these manual, specialized tools is a key differentiator in the world of footwear. They represent a commitment to a method that prioritizes quality over speed.

Mass Production vs. Custom Craftsmanship

These tools are hallmarks of traditional, handcrafted boot making. Mass-production facilities often use machines and different pattern-cutting techniques to approximate the shape, which can lead to a less precise fit and a shorter lifespan for the boot.

The Impact on Fit and Durability

The crimping process creates a superior fit over the instep, which is a common point of discomfort in poorly made boots. Similarly, the precise tension achieved with shank-lasting pincers ensures the boot's structural integrity will not fail over years of wear.

How This Informs Your Choice

Understanding these tools provides insight into the craft itself, whether you are an aspiring maker or a discerning buyer looking for quality.

- If your primary focus is becoming a bootmaker: Mastering the use of the crimp board is a non-negotiable step to achieving the authentic cowboy boot silhouette.

- If your primary focus is buying a quality boot: Look for a smooth, wrinkle-free instep, as this is a tell-tale sign of proper crimping and skilled craftsmanship.

Ultimately, these specialized tools are what allow a craftsman to transform durable materials into an iconic and functional piece of art.

Summary Table:

| Tool | Primary Function | Key Benefit |

|---|---|---|

| Crimp Board | Pre-shapes the vamp leather to form the boot's high instep. | Creates a seamless, wrinkle-free fit over the instep for superior comfort. |

| Shank-Lasting Pincers | Secures the leather tightly in the boot's arch area during lasting. | Ensures critical structural integrity and long-lasting arch support. |

Ready to produce high-quality cowboy boots with perfect fit and durability?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including expertly crafted cowboy boots that utilize the precise techniques described above.

We can help you deliver the superior craftsmanship your customers demand. Contact our team today to discuss your production needs.

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Premium Oil Wax Leather Safety Boots for Bulk Purchase

People Also Ask

- What are common indications for needing a walking boot? A Guide to Proper Injury Recovery

- What types of snow boots are available based on different needs? Choose the Right Boot for Your Winter Activity

- Why is it important to wear walking boots at night? Protect Your Recovery While You Sleep

- What are the characteristics of goat leather in cowboy boots? Discover Superior Comfort & Durability

- What are the advantages of waterproof boots? Stay Dry, Safe, and Comfortable in Any Environment

- How effective are snake-proof boots? A Guide to Safety and Buyer Cautions

- What should people with foot conditions consider when choosing walking shoes? Find the Perfect Fit for Lasting Comfort

- What type of winter boots are suitable for city or town use? Find the Perfect Urban Winter Boots