To find the best waterproof work boots, you need to look beyond the label and inspect three critical areas: the waterproofing method (like an internal membrane), the construction (sealed seams and sole), and the quality of the outer material, such as thick leather. These elements, combined with essential safety features like protective toes and slip-resistant outsoles, determine if a boot will truly keep you dry and safe.

The most reliable waterproof work boots don't just repel water from the outside; they are built with an internal waterproof, breathable membrane. True performance comes from understanding how the boot's construction and materials work together to provide a complete barrier against moisture.

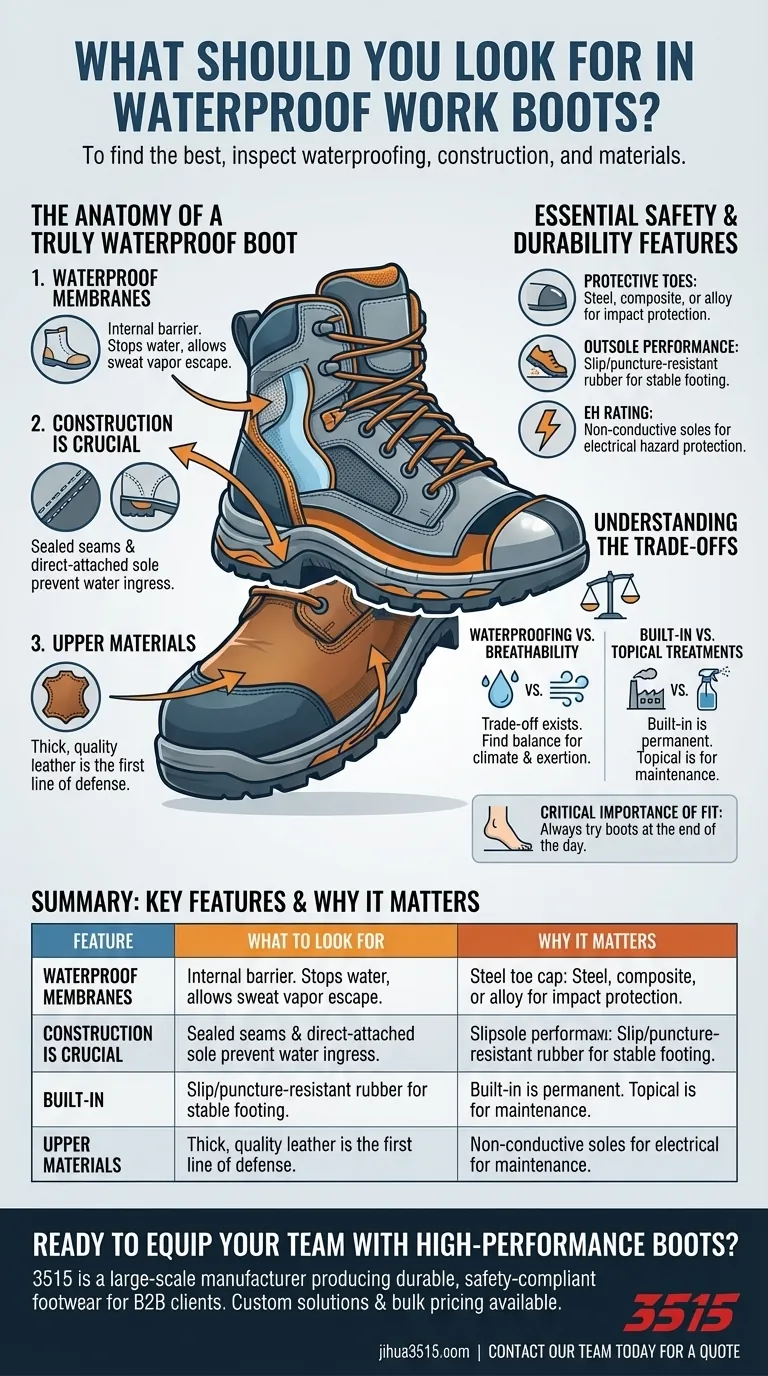

The Anatomy of a Truly Waterproof Boot

A "waterproof" tag can be misleading. True, lasting protection comes from specific design and construction choices that create an impenetrable barrier.

Beyond the Label: Waterproof Membranes

The most effective method for waterproofing is a bootie-style waterproof and breathable membrane built into the boot's lining. This internal layer acts as the primary barrier, stopping water from reaching your foot while allowing sweat vapor to escape.

This technology ensures your feet stay dry from both external elements and internal moisture, which is critical for preventing blisters and bacterial growth.

Construction is Crucial: Seams and Sole Attachment

A boot's weakest points are its seams. Look for boots with minimal stitching or factory-sealed seams, as these are the most common entry points for water.

The way the sole is attached is also vital. A direct-attached sole should have a perfect, waterproof seal where it meets the upper. If the sole is sewn on (Goodyear welt), ensure the stitching itself is waterproofed.

The First Line of Defense: Upper Materials

The outer material, typically thick, high-quality leather, serves as the first line of defense. While the internal membrane does the heavy lifting, a well-treated leather upper repels water, protects the membrane, and enhances the boot's overall durability.

Essential Safety and Durability Features

Waterproofing is just one component. A work boot must also provide robust protection against job site hazards.

Protective Toes

Nearly all work environments require protective toes. A steel toe is the traditional standard for impact protection. Modern boots may also feature composite or alloy toes, which are lighter alternatives that still meet safety standards.

The Foundation: Outsole Performance

The outsole is your connection to the ground. Look for chemical-resistant and slip-resistant rubber to ensure stable footing on wet or contaminated surfaces. Many outsoles are also designed to be puncture-resistant, protecting you from nails and other sharp objects.

Electrical Hazard (EH) Rating

For those working around live electrical circuits, an Electrical Hazard (EH) rated boot is essential. These boots are designed with non-conductive soles and heels to provide a secondary source of protection against electrocution.

Understanding the Trade-offs

Choosing the right boot means balancing competing features. Understanding these trade-offs is key to making an informed decision.

Waterproofing vs. Breathability

There is always a trade-off between keeping water out and letting sweat escape. While modern waterproof membranes are breathable, they will never be as airy as a non-waterproof boot. For hot climates or high-exertion jobs, finding a boot with the best possible breathability is crucial for all-day comfort.

Built-in vs. Topical Treatments

Factory-integrated waterproofing is far superior to temporary sprays or waxes. Built-in waterproofing is a permanent feature of the boot's construction. Exterior products are best used for maintenance—to condition the leather and bolster its water-repellency—not to create the primary waterproof barrier.

The Critical Importance of Fit

No feature can compensate for a poor fit. A boot that is too tight will restrict circulation, while a boot that is too loose will cause blisters. Always try boots on at the end of the day when your feet are slightly swollen to get the most accurate fit.

Making the Right Choice for Your Work

Select your boots based on the primary demands of your job.

- If your primary focus is safety in hazardous environments: Prioritize boots with a certified protective toe, an EH rating, and a chemical- and puncture-resistant outsole.

- If your primary focus is all-day comfort in wet conditions: Look for a boot with a proven waterproof/breathable membrane and pay close attention to achieving a perfect fit.

- If your primary focus is long-term durability for heavy use: Inspect the construction, favoring high-quality leather, sealed seams, and a securely attached sole.

Investing in a boot with the right construction ensures your feet stay protected, dry, and comfortable, no matter the conditions.

Summary Table:

| Key Feature | What to Look For | Why It Matters |

|---|---|---|

| Waterproofing Method | Internal, breathable membrane (e.g., bootie construction) | Creates a primary barrier; keeps feet dry from outside water and inside sweat. |

| Construction | Sealed seams; direct-attached or waterproofed welted sole | Prevents water ingress at the boot's weakest points. |

| Upper Material | Thick, high-quality leather (well-treated) | First line of defense; protects the membrane and enhances durability. |

| Safety Features | Protective toe (steel/composite), slip/puncture-resistant outsole, EH rating | Provides essential protection against job site hazards. |

Ready to Equip Your Team with High-Performance Waterproof Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof boots designed with the critical features outlined above—ensuring your customers stay dry, safe, and comfortable.

We offer custom solutions and bulk pricing to meet your specific market needs. Let's discuss your requirements and how we can support your business.

Contact our team today for a quote

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- What workplace hazards do safety toe boots protect against? Comprehensive Protection Guide

- What were some early hazards that safety footwear addressed? A Guide to Essential Foot Protection

- Why is the use of professional safety shoes critical for injection molding? Prevent Injuries with High-Impact Footwear