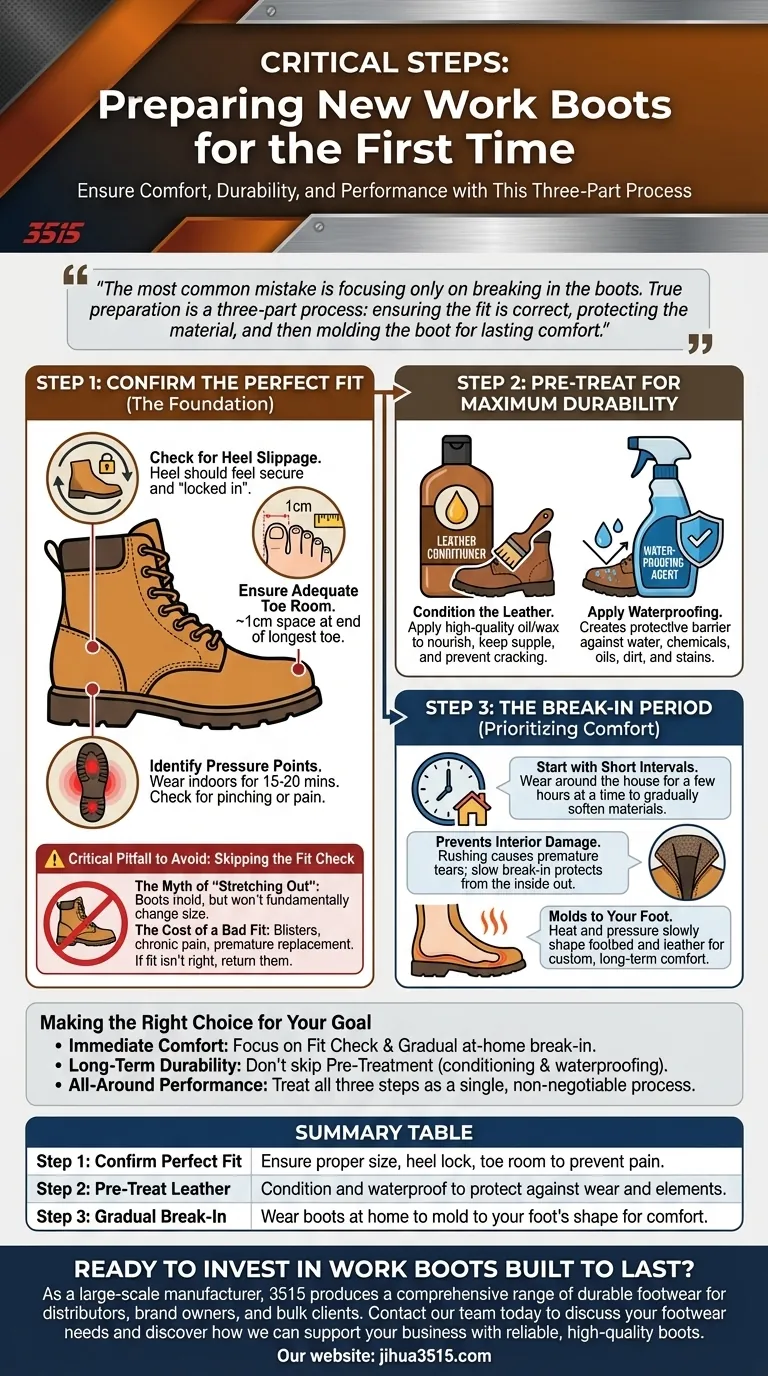

Before wearing new work boots for the first time, you must perform three critical steps in order: confirm a perfect fit, apply a leather conditioner and waterproofing agent, and begin the break-in process at home. This sequence ensures the boots are comfortable, durable, and ready for the demands of a worksite from day one.

The most common mistake is focusing only on breaking in the boots. True preparation is a three-part process: ensuring the fit is correct, protecting the material from the elements, and then molding the boot to your foot for lasting comfort.

Step 1: Confirm the Perfect Fit (The Foundation)

Before you apply any products or even wear them for an hour, you must verify that the boots fit correctly. No amount of conditioning or "breaking in" can fix a boot that is fundamentally the wrong size or shape for your foot.

Check for Heel Slippage

Your heel should feel secure and "locked in." Minor movement is acceptable, but any significant rubbing or lifting as you walk indicates a poor fit that will lead to blisters and instability.

Ensure Adequate Toe Room

There should be about a centimeter (roughly a thumb's width) of space between the end of your longest toe and the tip of the boot. Your feet swell throughout the day, and this space prevents your toes from hitting the end.

Identify Pressure Points

Wear the boots indoors on a clean surface for at least 15-20 minutes. Walk around, go up and down stairs, and pay close attention to any specific points of pain, pinching, or uncomfortable pressure.

Step 2: Pre-Treat for Maximum Durability

Once you've confirmed the fit, the next step is to protect your investment. Treating the boots before their first exposure to a harsh environment is crucial for their longevity.

Condition the Leather

Apply a natural leather care product like a high-quality oil, wax, or conditioner. This nourishes the leather, keeping it supple and preventing it from drying out and cracking over time.

Apply a Waterproofing Agent

After conditioning, apply a waterproofing agent. This creates an invisible protective barrier on the surface that repels water, chemicals, oils, dirt, and stains, preventing them from penetrating and damaging the material. Most sprays are suitable for various materials, including leather, suede, and nubuck.

Step 3: The Break-In Period (Prioritizing Comfort)

Never wear a brand-new pair of work boots for a full workday. A gradual break-in period allows the stiff materials to mold to the unique shape of your feet, preventing pain and potential damage to the boot's interior.

Start with Short Intervals

Begin by wearing your new boots around the house for just a few hours at a time. This gradually softens the leather and lining without the stress of a full day's work.

Prevents Interior Damage

Rushing the break-in process can cause premature tears in the boot's lining as your foot fights against the rigid structure. A slow break-in protects the boot from the inside out.

Molds to Your Foot

This process is what truly customizes the boot's fit. The heat and pressure from your foot slowly shape the footbed and leather, creating a fit that is uniquely yours and provides long-term comfort.

A Critical Pitfall to Avoid: Skipping the Fit Check

The single most costly mistake is attempting to "break in" a boot that simply does not fit. This is the one problem that cannot be fixed later.

The Myth of "Stretching Out"

While leather boots will mold and become more flexible, they will not fundamentally change in size. A boot that is too short or too narrow will always be too short or too narrow.

The Cost of a Bad Fit

Ignoring pressure points or a lack of toe room will inevitably lead to blisters, chronic foot pain, and the need to replace expensive boots prematurely. If the fit isn't right from the start, return them.

Making the Right Choice for Your Goal

Your preparation should align with what you value most in your work boots.

- If your primary focus is immediate comfort: The fit check and a gradual at-home break-in period are the most important steps you can take.

- If your primary focus is long-term durability: Do not skip the pre-treatment stage of conditioning and waterproofing before the first wear.

- If your primary focus is all-around performance: Treat all three steps—fit, treatment, and break-in—as a single, non-negotiable process.

Properly preparing your new boots is an investment in your comfort, safety, and productivity.

Summary Table:

| Step | Key Action | Primary Goal |

|---|---|---|

| 1 | Confirm Perfect Fit | Ensure proper size, heel lock, and toe room to prevent pain. |

| 2 | Pre-Treat Leather | Condition and waterproof to protect against wear and elements. |

| 3 | Gradual Break-In | Wear boots at home to mold them to your foot's shape for comfort. |

Ready to invest in work boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots designed for superior comfort and long-term performance right out of the box.

Contact our team today to discuss your footwear needs and discover how we can support your business with reliable, high-quality boots.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

People Also Ask

- What is the purpose of safety toe boots? Ultimate Protection for Your Work Environment

- What is the biggest enemy of leather boots? Protect Your Investment from Water Damage

- Which boots do real cowboys wear? Discover the Top Work Boots for Ranch Durability

- What methods can improve the waterproofing of work boots? Boost Durability & Protection

- What materials are typically used for the outsole of light work boots? Find the Perfect Balance of Durability & Comfort

- How does cleaning your work boots help in their maintenance? Extend Lifespan & Boost Safety

- How do IoT sensor environments contribute to the lifecycle management of industrial boots? Smart Data-Driven Safety

- What are the specific requirements for wildland firefighting boots under NFPA 1977? Essential Safety Guide