The most effective methods to improve the waterproofing of work boots involve a two-pronged approach: applying an appropriate topical sealant and understanding the boot's inherent construction. Products like waxes, creams, or sprays create an external barrier, with the best choice depending on your boot's material. This external treatment works in concert with the boot's seams and any built-in waterproof liners to provide comprehensive protection.

The key to truly waterproof work boots is not just applying a product, but implementing a system of regular maintenance. This involves selecting the right sealant for your boot's material and applying it correctly to a clean surface to reinforce its natural water resistance.

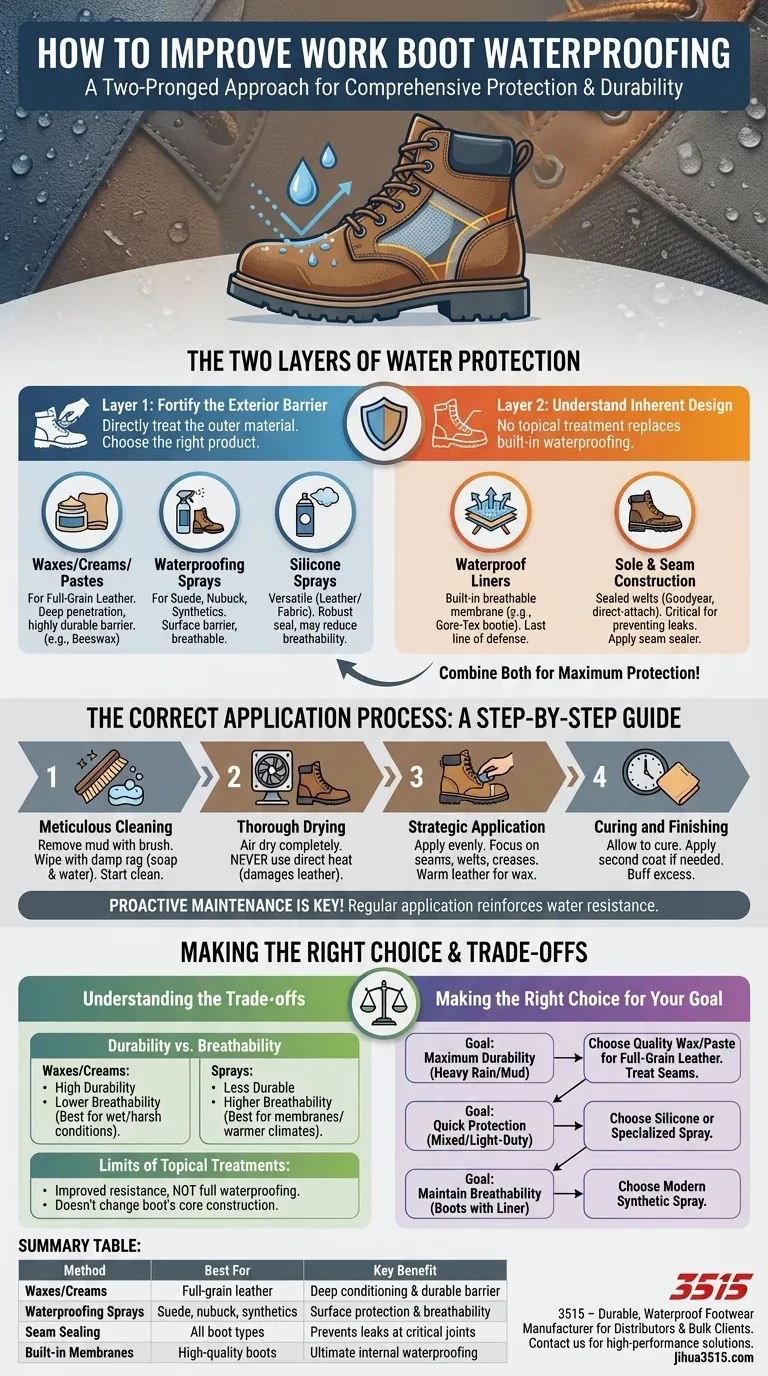

The Two Layers of Water Protection

True water protection for work boots relies on two distinct layers: the external barrier you create and the internal construction of the boot itself. Understanding both is essential for keeping your feet dry.

Layer 1: Fortifying the Exterior Barrier

The most direct way to improve water resistance is by treating the boot's outer material. The product you choose must match the material it's intended to protect.

- Waxes, Creams, and Pastes: These are ideal for full-grain leather boots. They penetrate the leather's pores, conditioning the material while creating a highly durable, water-repellent barrier. Beeswax and mink oil are common, effective ingredients.

- Waterproofing Sprays: Sprays are the best choice for suede, nubuck, and synthetic fabric boots. They form a surface-level barrier without clogging the material's texture or significantly impacting breathability.

- Silicone Sprays: This is a versatile option that works on many materials, including leather and fabric. It creates a robust seal but can sometimes reduce the breathability of the material.

Layer 2: Understanding Your Boot's Inherent Design

No topical treatment can fully compensate for a boot that isn't designed for wet conditions. Key structural elements determine a boot's foundational water resistance.

- Waterproof Liners: Many high-quality work boots feature a built-in waterproof, breathable membrane (like a Gore-Tex bootie). This liner is your last line of defense, stopping water that gets past the outer material.

- Sole and Seam Construction: The area where the boot upper meets the sole (the welt) is a common failure point. Goodyear welt construction and direct-attach methods are often sealed for better water resistance than simple cemented soles. Applying a seam sealer to these areas before general waterproofing can drastically improve performance.

The Correct Application Process: A Step-by-Step Guide

Applying a waterproofing product incorrectly can be as ineffective as not applying one at all. Following a precise method ensures the best possible seal.

Step 1: Meticulous Cleaning

You must start with a perfectly clean and dry surface. Use a stiff brush to remove all caked-on mud and debris, then use a damp rag with a simple soap and water solution to wipe away fine dirt.

Step 2: Thorough Drying

Allow the boots to air dry completely in a well-ventilated area. Never use a direct heat source like a radiator or campfire, as this can crack and damage leather, compromising its integrity. A fan can help speed up the process.

Step 3: Strategic Application

Read your waterproofing product's instructions carefully. For leather boots, you can gently warm the surface with a hairdryer to help wax-based products absorb more deeply.

Apply the product evenly across the entire boot, paying special attention to seams, welts, creases, and around eyelets. Use a clean rag or applicator for waxes and creams.

Step 4: Curing and Finishing

Let the boots sit for the recommended time to allow the product to cure. For waxes and creams, you may need to apply a second coat. Once cured, buff off any excess product with a clean, dry cloth.

Understanding the Trade-offs

Choosing a waterproofing method involves balancing durability, ease of use, and the boot's performance characteristics.

Durability vs. Breathability

Waxes and heavy creams offer the most durable protection but can slightly reduce the breathability of leather. This is a worthy trade-off for those working in consistently wet, harsh conditions.

Sprays are less durable and require more frequent reapplication (e.g., monthly or after a thorough soaking). However, they have a minimal impact on breathability, making them ideal for boots with waterproof membranes or for use in warmer climates.

The Limits of Topical Treatments

It is crucial to understand that applying a waterproofing product improves water resistance, but it cannot make a standard boot fully waterproof. A topical treatment will not make a mesh running shoe suitable for standing in a puddle. The boot's underlying construction sets the ultimate limit of its protection.

Common Application Mistakes

The most common failure is applying sealant to a dirty or damp boot. This traps dirt and moisture, preventing the product from bonding correctly and potentially leading to material decay. Using the wrong product, such as a heavy wax on suede, will ruin the material's texture and finish.

Making the Right Choice for Your Goal

Your specific work environment and boot type should dictate your waterproofing strategy.

- If your primary focus is maximum durability in heavy rain or mud: Choose a high-quality wax or paste for your full-grain leather boots, and be sure to treat the seams first.

- If your primary focus is quick protection for mixed materials or light-duty work: A silicone-based or specialized waterproofing spray is your most efficient option.

- If your primary focus is maintaining the breathability of boots with a waterproof liner: Use a modern synthetic spray specifically designed not to clog the pores of the outer material or the liner's membrane.

Proactive and consistent maintenance is the single most important factor in keeping your feet dry and your boots in service for the long haul.

Summary Table:

| Method | Best For | Key Benefit |

|---|---|---|

| Waxes/Creams | Full-grain leather | Deep conditioning & durable barrier |

| Waterproofing Sprays | Suede, nubuck, synthetics | Surface protection & breathability |

| Seam Sealing | All boot types | Prevents leaks at critical joints |

| Built-in Membranes | High-quality boots | Ultimate internal waterproofing |

Need work boots built to withstand the toughest conditions? As a large-scale manufacturer, 3515 produces a comprehensive range of durable, waterproof footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes designed for maximum protection and comfort. Contact us today to discuss your specific needs and discover how we can deliver reliable, high-performance footwear for your market.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What were some early hazards that safety footwear addressed? A Guide to Essential Foot Protection

- What are the requirements for oilfield boots? Essential Safety & Durability Features

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- What are the advantages of rubber soles for work boots? Unbeatable Grip & Durability