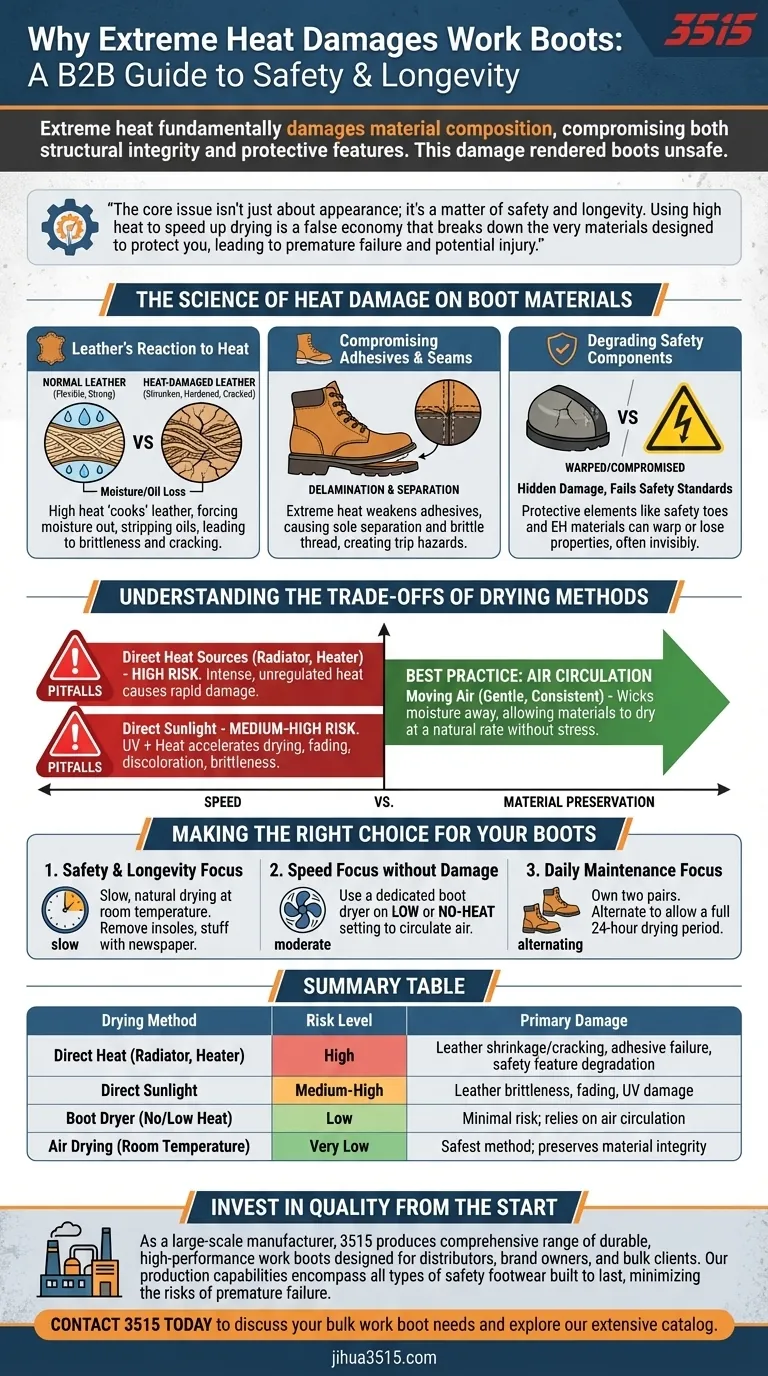

Extreme heat should be avoided when drying work boots because it fundamentally damages their material composition, compromising both their structural integrity and protective features. This damage, which includes leather shrinkage, hardening, and cracking, can occur even without visible signs, rendering the boots unsafe for their intended purpose.

The core issue isn't just about appearance; it's a matter of safety and longevity. Using high heat to speed up drying is a false economy that breaks down the very materials designed to protect you, leading to premature failure and potential injury.

The Science of Heat Damage on Boot Materials

Work boots are engineered from specific materials chosen for their durability, support, and protective qualities. Exposing them to intense, direct heat initiates a rapid breakdown process that permanently alters these materials.

Leather's Reaction to Heat

Leather is a natural material composed of a complex matrix of protein fibers. It retains moisture to stay flexible and strong.

When you apply high heat, you are essentially "cooking" the leather. This forces the moisture out too quickly, causing the protein fibers to constrict and shrink. The natural oils within the leather are also stripped away, leading to a brittle, hardened material that is prone to cracking with every step.

Compromising Adhesives and Seams

Modern work boots rely on powerful adhesives to bond the sole to the upper part of the boot. These glues are formulated to withstand incredible stress but have a specific temperature tolerance.

Extreme heat can soften and weaken these adhesives, causing the sole to delaminate or separate from the rest of the boot. This not only ruins the boot but creates a significant trip hazard. Similarly, the thread used in stitching can become brittle and lose its tensile strength.

Degrading Safety Components

Specialized safety features are often the first victims of heat damage.

Protective elements like composite safety toes, metatarsal guards, and electrical hazard (EH) rated materials can be warped or have their non-conductive properties compromised by high temperatures. This hidden damage means a boot that looks fine may no longer meet critical safety standards.

Understanding the Trade-offs of Drying Methods

Every drying method involves a trade-off between speed and material preservation. Understanding these helps in making the right choice.

Pitfall: Direct Heat Sources

Placing boots next to a radiator, fireplace, or space heater is the most common mistake. While it seems fast, this method provides intense, unregulated heat that is guaranteed to cause the damage described above.

Pitfall: Direct Sunlight

Leaving boots in direct sunlight also poses a risk. The ultraviolet (UV) radiation combined with the heat accelerates the drying of oils in the leather, leading to fading, discoloration, and brittleness over time.

The Best Practice: Air Circulation

The safest and most effective drying principle is not heat, but airflow. Moving air wicks moisture away from the boot's surface gently and consistently, allowing the materials to dry at a natural rate without stress.

Making the Right Choice for Your Boots

Your goal dictates the best approach to drying. Follow these guidelines to preserve your investment and ensure your safety.

- If your primary focus is safety and longevity: Always opt for slow, natural drying at room temperature. Remove insoles, stuff the boots with newspaper to absorb initial moisture, and place them in a dry, well-ventilated area.

- If your primary focus is speed without damage: Use a dedicated boot dryer on a low or no-heat setting. These devices are designed to circulate air, which is the key to safe and efficient drying.

- If your primary focus is daily maintenance: The best strategy is to own two pairs of boots. Alternating them allows one pair to dry completely for a full 24 hours while you wear the other.

Properly drying your work boots is a critical maintenance step that directly impacts their performance and your personal safety on the job.

Summary Table:

| Drying Method | Risk Level | Primary Damage |

|---|---|---|

| Direct Heat (Radiator, Heater) | High | Leather shrinkage/cracking, adhesive failure, safety feature degradation |

| Direct Sunlight | Medium-High | Leather brittleness, fading, UV damage |

| Boot Dryer (No/Low Heat) | Low | Minimal risk; relies on air circulation |

| Air Drying (Room Temperature) | Very Low | Safest method; preserves material integrity |

Invest in Quality from the Start

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-performance work boots designed for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear built to last, minimizing the risks of premature failure.

Let us help you provide superior footwear that stands the test of time and protects your workforce.

Contact 3515 today to discuss your bulk work boot needs and explore our extensive catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors