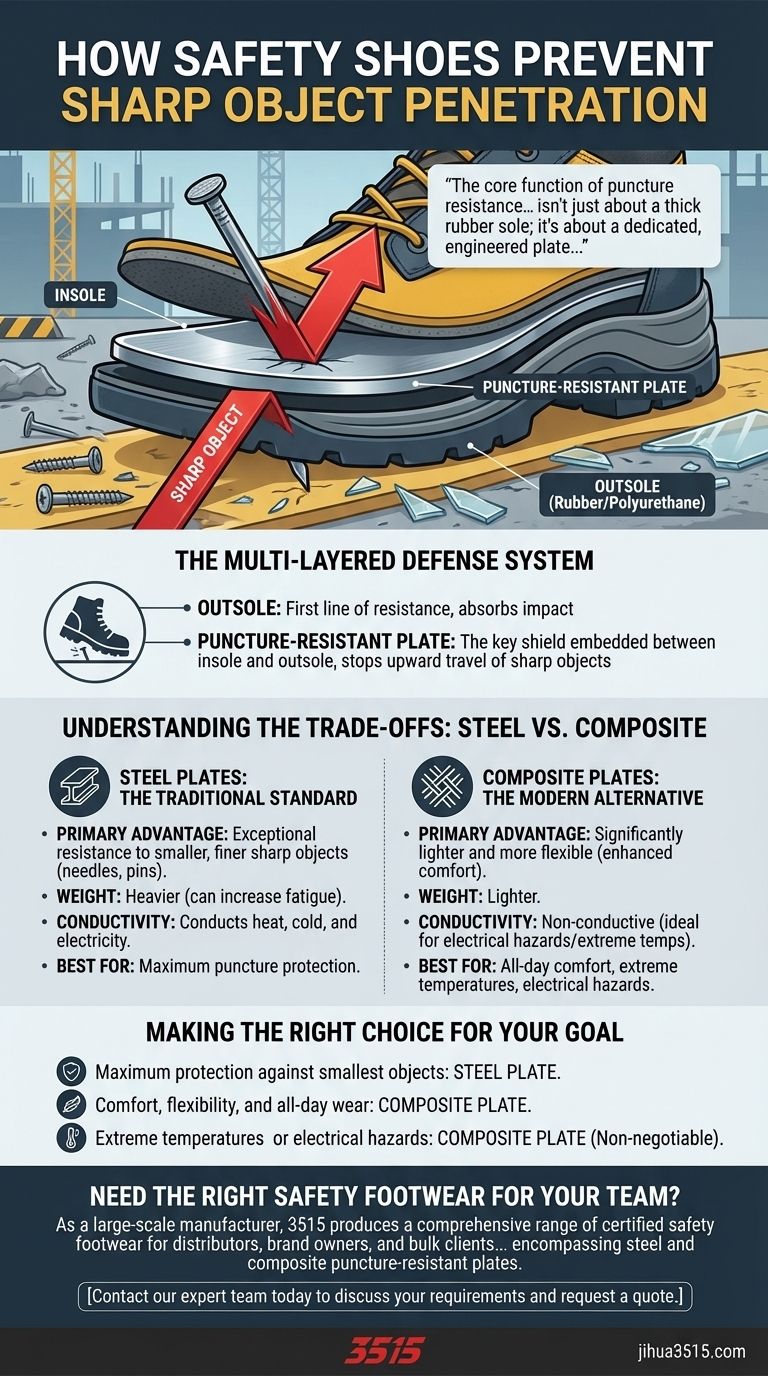

In short, safety shoes prevent sharp object penetration primarily through a puncture-resistant plate strategically placed within the sole. This protective barrier, typically made of steel or advanced composite materials, is designed to stop nails, screws, glass shards, and other hazards from piercing the shoe and injuring the foot.

The core function of puncture resistance in safety footwear isn't just about a thick rubber sole; it's about a dedicated, engineered plate designed to withstand specific piercing forces, ensuring protection against common and dangerous workplace hazards.

How Puncture Protection is Engineered

The effectiveness of a safety shoe against sharp objects is determined by the design and materials of its sole structure. It's a multi-layered system working in concert.

The Puncture-Resistant Plate

The key component is the puncture-resistant plate. This is a thin but incredibly durable sheet embedded between the insole and the outsole of the shoe.

Its sole purpose is to act as a shield. When a worker steps on a sharp object like a nail, the object pushes against the outsole, but the plate stops its upward travel before it can reach the foot.

The Role of the Outsole

While the plate provides the primary puncture defense, the outsole—the thick, outer layer of the sole that contacts the ground—offers the first line of resistance.

Made of durable materials like rubber or polyurethane, its thickness helps to slow down and absorb some of the initial force from a sharp object, reducing the direct impact on the protective plate.

Understanding the Trade-offs: Steel vs. Composite

The material used for the puncture-resistant plate has a significant impact on the shoe's overall performance, comfort, and suitability for different environments. There is no single "best" material; the choice involves clear trade-offs.

Steel Plates: The Traditional Standard

Steel plates have been the industry standard for decades. Their primary advantage is their exceptional resistance to penetration from smaller, finer sharp objects like needles or pins.

However, steel is heavier, which can increase fatigue over a long workday. It is also a conductor of heat, cold, and electricity, making it less suitable for extreme temperature environments or jobs with electrical hazards.

Composite Plates: The Modern Alternative

Composite plates are made from non-metal materials like Aramid fibers (such as Kevlar) or other advanced woven fabrics. Their main benefit is being significantly lighter and more flexible than steel, which greatly enhances comfort.

These materials do not conduct heat, cold, or electricity, making them ideal for a wider range of work conditions. The main trade-off is that while they meet regulatory standards for nail penetration, they may offer less resistance to extremely fine, sharp objects compared to steel.

Making the Right Choice for Your Goal

Selecting the correct type of puncture protection depends entirely on your specific work environment and priorities.

- If your primary focus is maximum protection against the smallest sharp objects: A steel plate offers the most robust and proven defense against fine-point punctures.

- If your primary focus is comfort, flexibility, and all-day wear: A composite plate provides certified protection while significantly reducing weight and improving comfort.

- If your primary focus is working in extreme temperatures or around electrical hazards: A composite plate is the non-negotiable choice due to its non-conductive properties.

Ultimately, understanding the technology behind puncture resistance empowers you to choose footwear that truly meets the demands of your job.

Summary Table:

| Feature | Steel Plate | Composite Plate |

|---|---|---|

| Primary Advantage | Superior resistance to fine, sharp objects | Lightweight, flexible, and more comfortable |

| Weight | Heavier | Lighter |

| Conductivity | Conducts heat, cold, and electricity | Non-conductive |

| Best For | Maximum puncture protection | All-day comfort, extreme temperatures, electrical hazards |

Need the Right Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including models with both steel and composite puncture-resistant plates.

We can help you equip your workforce with durable, comfortable, and compliant footwear tailored to your specific hazards and environment.

Contact our expert team today to discuss your requirements and request a quote.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What is one important type of personal protective equipment for composite industry workers? Composite-Toe Boots

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide

- What additional protection do S2 safety shoes offer compared to S1? The Key Difference is Water Resistance

- What industries are men's work shoes suitable for? Find the Right Safety Shoe for Your Job

- What are the advantages of using professional safety shoes with arch support for sewing operators? Boost Productivity

- Why are professional-grade Safety Shoes necessary for forest logging? Guard Against Critical Risks in Forestry Work

- What are the different types of firefighter boots available? Choose the Right Boot for Your Mission

- What are the different names for safety shoes? Choose the Right Protection for Your Job