Among the most critical pieces of personal protective equipment, composite-toe work boots are a foundational safety requirement for workers in composite production facilities. They are specifically designed to protect against impact and compression from heavy materials and equipment, a constant risk in this environment.

The core challenge in composites manufacturing is selecting PPE that addresses multiple, industry-specific hazards simultaneously. Composite-toe boots are the standard not just for impact protection, but because their non-metallic nature is essential for mitigating electrical risks and preventing magnetic interference.

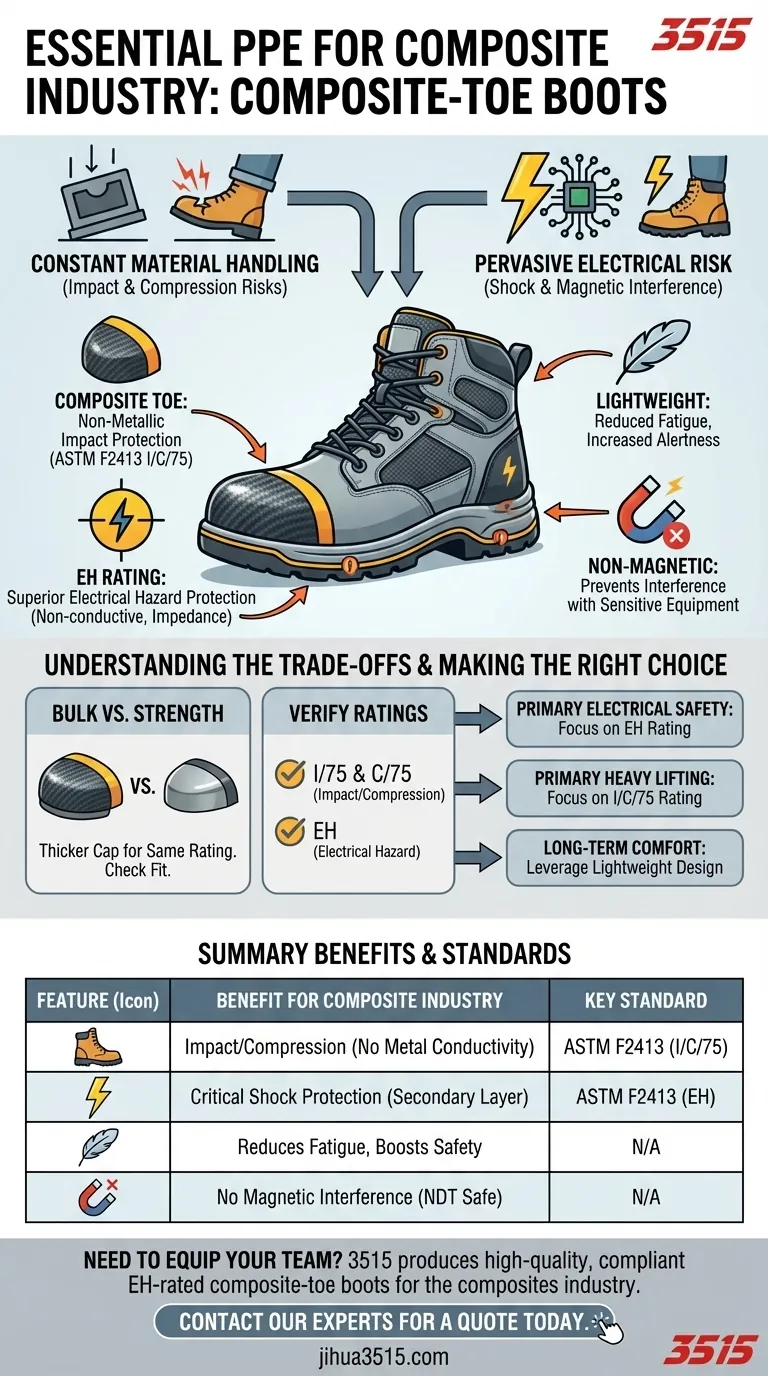

The Unique Hazards of a Composites Environment

To understand the equipment, you must first understand the risks inherent to the workplace. Composites facilities present a unique combination of physical and electrical dangers.

Constant Material Handling

Workers frequently move, lift, and position heavy molds, tooling, and raw materials. This creates a significant risk of foot injuries from dropped objects (impact) or "roll-over" incidents where feet can be crushed (compression).

Pervasive Electrical Risk

The machinery used for curing, cutting, and finishing composites often involves high-voltage electrical systems. This introduces a persistent electrical shock hazard that must be managed through appropriate PPE.

Potential for Magnetic Interference

Some advanced facilities use sensitive electronic equipment or non-destructive testing (NDT) scanners. In these zones, metallic components in clothing or footwear can interfere with diagnostics or create safety issues.

Why Composite-Toe Boots are the Standard

Composite-toe boots directly address the specific combination of hazards found in composites manufacturing, making them superior to alternatives like steel-toe boots in this context.

Meeting Impact Standards Without Metal

The primary function of a safety toe is to protect against impact and compression, typically rated by the ASTM F2413 standard. Composite materials (like Kevlar, carbon fiber, or plastic) are engineered to meet or exceed these same stringent standards as steel.

This provides equivalent protection from physical threats without introducing the conductivity and magnetic properties of metal.

Superior Electrical Hazard (EH) Protection

This is the most critical advantage. Because composite materials do not conduct electricity, boots designed with them can achieve an Electrical Hazard (EH) rating.

An EH-rated boot is designed to impede the flow of electricity, providing a vital secondary layer of protection against accidental contact with live electrical circuits. In an environment rich with electrical equipment, this feature is non-negotiable.

Lighter Weight for Reduced Fatigue

Composite safety caps are significantly lighter than steel ones. While this may seem like a minor comfort, it translates directly to reduced worker fatigue over a long shift.

Less fatigue leads to greater awareness and a lower likelihood of accidents, contributing to overall facility safety.

Understanding the Trade-offs

While composite-toe is the standard for this industry, it's important to be aware of the practical differences when selecting your specific footwear.

Bulk vs. Strength

To achieve the same impact rating as steel, a composite cap must often be slightly thicker or bulkier. This can affect the fit and profile of the boot, making it crucial to try on different models to ensure a comfortable and secure fit.

Not a Universal Solution

The term "composite" is broad. Always verify the boot's specific ratings. Confirm it has the necessary impact (I/75) and compression (C/75) ratings and, most importantly, the EH rating for your work environment.

Making the Right Choice for Your Role

Your specific tasks should guide your final selection.

- If your primary focus is electrical safety: Ensure the boot is explicitly marked with an "EH" rating, verifying it meets ASTM standards for electrical hazard protection.

- If your primary focus is handling heavy molds: Confirm the boot carries the highest impact and compression ratings (I/75 and C/75) to protect against crush injuries.

- If your primary focus is long-term comfort and mobility: Leverage the lightweight nature of composite-toe boots to reduce fatigue, but never sacrifice the required safety ratings.

Ultimately, choosing the right PPE is an active process of matching the equipment's features to your environment's specific risks.

Summary Table:

| Feature | Benefit for Composite Industry | Key Standard |

|---|---|---|

| Composite Toe | Protects from impact/compression without metal conductivity | ASTM F2413 (I/C/75) |

| EH Rating | Critical secondary protection against electrical shock hazards | ASTM F2413 (EH) |

| Lightweight | Reduces worker fatigue, increasing alertness and safety | N/A |

| Non-Metallic | Prevents magnetic interference with sensitive equipment | N/A |

Need to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of EH-rated composite-toe boots and other safety footwear designed for the specific hazards of the composites industry. We provide high-quality, compliant PPE for distributors, brand owners, and bulk clients.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites