Okay, so I need to craft a definitive guide for professionals on the differences between S1 and S2 safety shoes. My goal is to be a trusted advisor, not just a regurgitator of information. I want to solve the user's real problem.

Firstly, I'm breaking down the request. I know the user is smart and needs a clear, unbiased explanation, not marketing fluff. I'm focusing on their deep need, not just the surface question. They don't just want to know what S2 offers more than S1, but why it matters and which to choose for a specific environment.

To make this clear, I need to be objective, authoritative, and extremely clear and easy to follow. Short paragraphs, headings, and bolding are essential. The answer needs to be easy to find, so I'm thinking a bold, direct opening statement, and a core takeaway box at the start.

I've looked at the provided references. I'm synthesizing the key points: S2 adds water resistance to everything S1 has. But, the real heart of it is that all S-rated shoes are fundamentally built to the same impact and compression standards. I need to use this to bust the myth that S2 is just "better" or "stronger".

So, the structure is forming in my mind. I'll start with the bold hook: "The critical difference between S2 and S1 safety shoes is water resistance." Then, I'll put a concise takeaway box.

I'll then build a framework:

- The Shared Foundation: I'll make it clear that the toecap and impact protection are the same between S1 and S2. This is the common starting point.

- The Key Differentiator: I'll explain that S2 is all about water resistance. Not waterproof, but water resistant. I'll connect this to practical, everyday concerns about foot hygiene and comfort.

- The Trade-offs: Cost, breathability – I'll be upfront about the pros and cons, especially calling out that S2 isn't appropriate for everyone or every job.

- Actionable Advice: I'll end with a direct, bulleted list that gives specific recommendations: S1 for dry environments, S2 for damp ones.

Finally, I'll empower the user with a strong closing sentence. This isn't about numbers; it's about making an informed decision for their unique workplace.

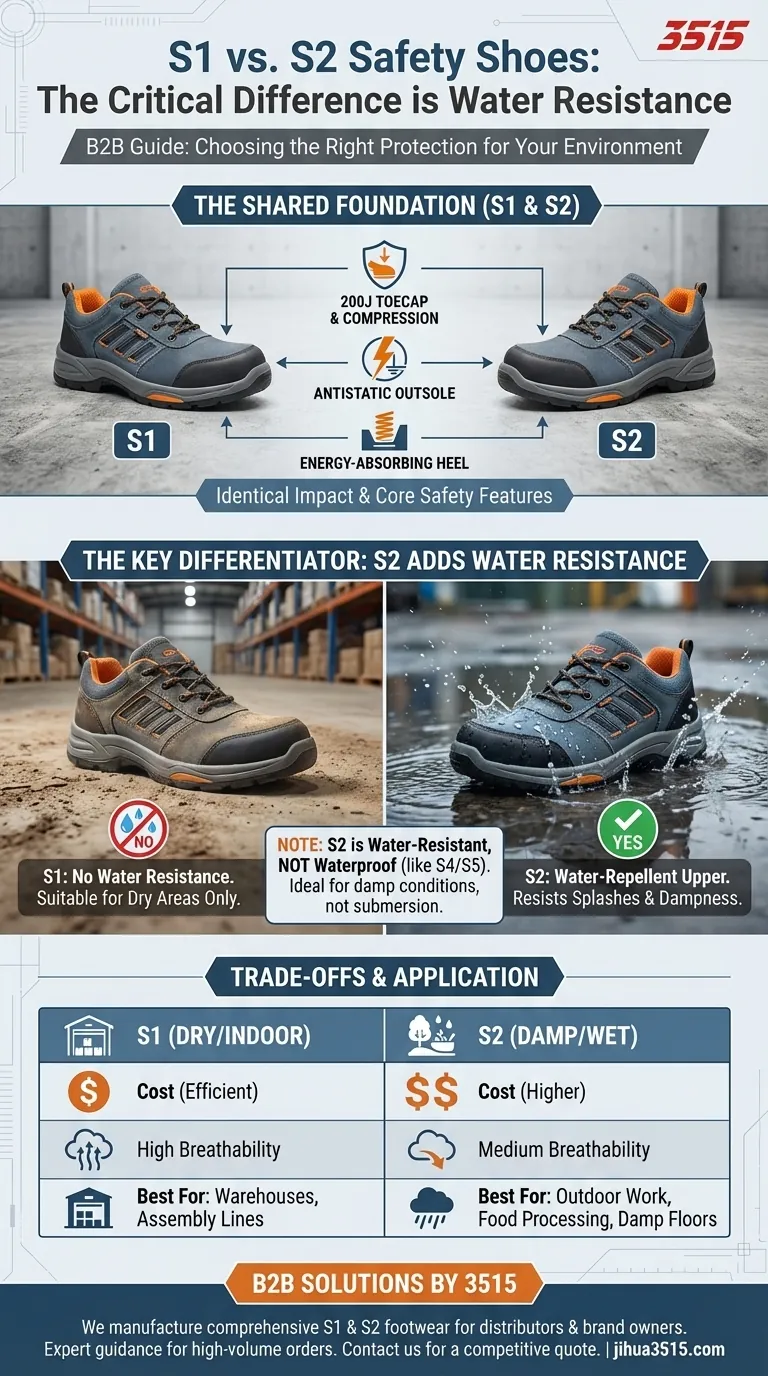

I'm confident I can make this a valuable, useful resource for the user. The critical difference between S2 and S1 safety shoes is water resistance. Both ratings share the same fundamental safety features for impact, compression, and static discharge. However, an S2 rated shoe adds a water-repellent upper, specifically designed to protect your feet in damp or wet working conditions.

The choice between S1 and S2 is not about which is "stronger" against impacts, but about matching the footwear to your work environment's moisture level. S1 is the standard for dry areas, while S2 is required for environments where exposure to water is likely.

The Shared Foundation: What S1 and S2 Both Guarantee

Before focusing on the differences, it's crucial to understand the baseline protection that both S1 and S2 ratings provide. They are built upon the same core safety principles mandated by the EN ISO 20345 standard.

Identical Impact and Compression Resistance

All safety footwear in the S-class, including S1 and S2, must have a protective toecap.

This toecap is tested to withstand an impact energy of 200 joules and a compression force of 15,000 newtons. This protects your toes from heavy falling objects and crushing hazards.

The Three Core S1 Features

The S1 rating establishes the minimum requirements for a professional safety shoe. These features are also present in every S2 shoe.

- Protective Toecap: As mentioned, this is the primary defense against impact and compression.

- Antistatic Outsole: This feature safely dissipates electrostatic charges, preventing static sparks that could ignite flammable substances or damage sensitive electronic components.

- Energy-Absorbing Heel: This design reduces the impact on your joints and back with every step, minimizing fatigue and long-term strain during long shifts.

The Key Differentiator: Adding Water Protection

The step up from S1 to S2 is focused entirely on one environmental hazard: water.

What S2 Water Resistance Means

The primary addition for an S2 rating is an upper material that prevents water penetration and water absorption.

This means the shoe's shaft will resist soaking through when exposed to splashes, rain, or damp surfaces, keeping the wearer's foot dry.

The Importance of a Dry Environment

Keeping feet dry is not just a matter of comfort. It is essential for workplace hygiene and preventing health issues like fungal infections.

In outdoor work or industries like food processing and cleaning, this feature is non-negotiable for employee well-being and performance.

Understanding the Trade-offs

Choosing a higher rating isn't always better. Selecting the wrong shoe for your environment can be inefficient and counterproductive.

S2 is Not Fully Waterproof

It is critical to distinguish between water resistance (S2) and waterproof (S4/S5). An S2 shoe is ideal for damp floors and splashes.

If your work involves standing in water or full immersion, you need the fully molded polymer construction of an S4 or S5 safety boot (e.g., a wellington).

Cost vs. Environmental Need

S2 footwear often costs more due to the treated materials and construction required for water resistance.

If you work exclusively in a dry, indoor environment like a warehouse or assembly line, the S1 rating provides all the necessary protection at a more efficient price point.

Breathability Considerations

While modern materials are highly advanced, adding water-repellent properties can sometimes reduce a shoe's overall breathability.

In a hot, dry workplace, a highly breathable S1 shoe might offer superior long-term comfort over an S2 equivalent.

Making the Right Choice for Your Environment

Your specific work conditions should be the only factor in this decision. Both S1 and S2 offer identical protection from the most common mechanical risks.

- If you work exclusively in dry, indoor environments: An S1 shoe provides the necessary impact and antistatic protection without the unnecessary cost of water resistance.

- If you work in damp conditions or frequently move between indoors and outdoors: The water resistance of an S2 shoe is essential for keeping your feet dry, safe, and comfortable.

- If your primary hazard is falling objects but the environment is always dry: Both S1 and S2 offer the same toecap protection, making S1 the more logical and cost-effective choice.

Understanding this fundamental difference empowers you to select safety footwear based on the specific risks of your environment, not just a higher number.

Summary Table:

| Feature | S1 Safety Shoes | S2 Safety Shoes |

|---|---|---|

| Protective Toecap (200J impact) | ✅ Yes | ✅ Yes |

| Energy-Absorbing Heel | ✅ Yes | ✅ Yes |

| Antistatic Properties | ✅ Yes | ✅ Yes |

| Water-Resistant Upper | ❌ No | ✅ Yes |

| Best For | Dry, indoor environments (e.g., warehouses) | Damp or wet environments (e.g., food processing, outdoors) |

Need the Right Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of S1 and S2 certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the perfect match for your specific work environment and volume needs.

We provide:

- Expert Guidance: Help you select the correct safety rating (S1, S2, S3) for your application.

- High-Volume Production: Reliable supply for large orders with consistent quality.

- Customization Options: Develop private-label footwear tailored to your brand and safety standards.

Let's discuss your requirements. Contact our team today for a competitive quote and expert support.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.