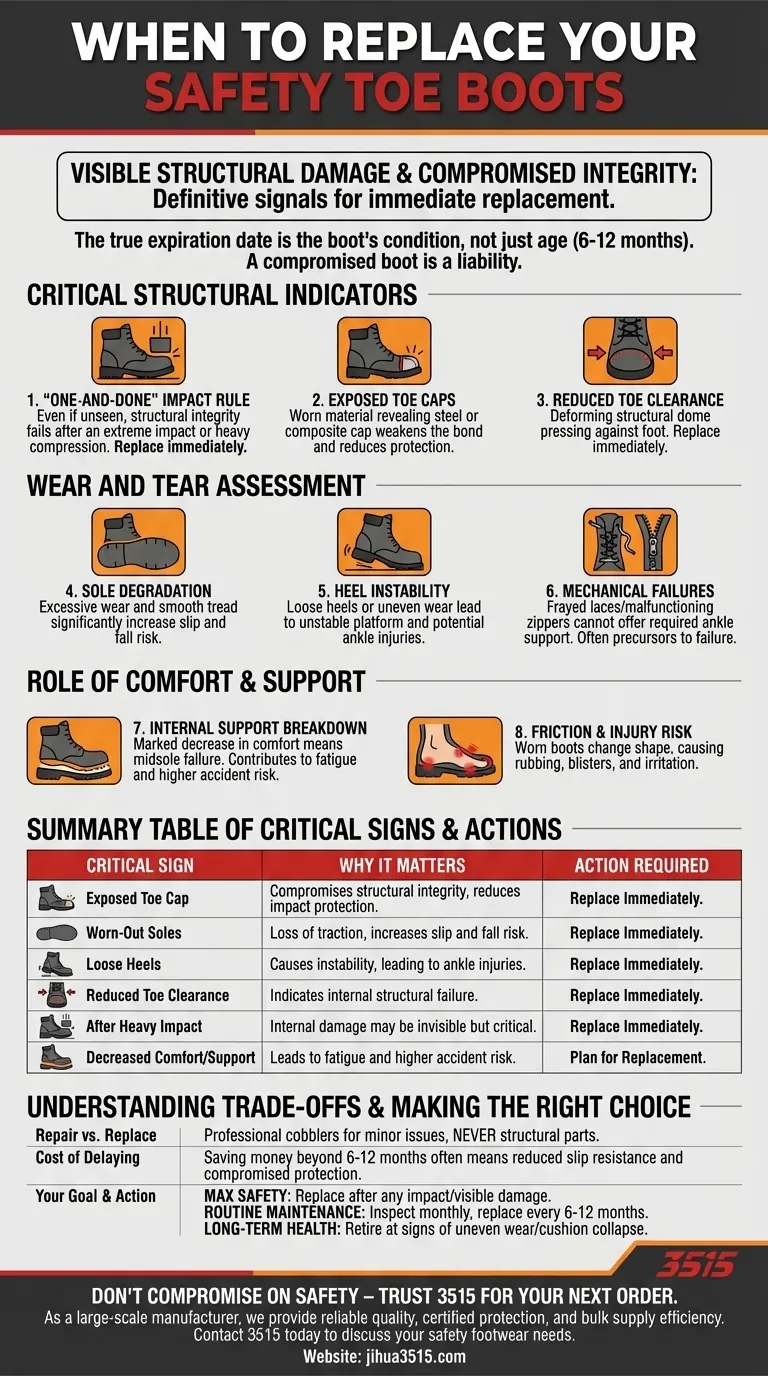

Visible structural damage and compromised integrity are the definitive signals that your safety toe boots have reached the end of their lifespan. You must replace them immediately if you see exposed steel caps, worn-out soles, loose heels, or reduced clearance in the toe box, as well as after any event where the boot sustains a heavy impact.

While general guidelines suggest replacement every 6 to 12 months, the true expiration date is determined by the boot's condition. A safety boot that has survived a significant impact or lost its tread is no longer a protective tool; it is a liability.

Critical Structural Indicators

The "One-And-Done" Impact Rule

The most important rule in safety footwear is often invisible. If your boot experiences an extreme impact or heavy compression, you must replace it immediately.

Even if the outer material looks fine, the structural integrity of the safety toe—whether steel, composite, or alloy—may be compromised. A weakened toe cap cannot be trusted to protect you a second time.

Exposed Toe Caps

Inspect the leather or synthetic material covering the toe box. If the protective material has worn away to reveal the exposed steel or composite cap, the boot is structurally failing.

This exposure weakens the bond between the cap and the boot, reducing its ability to deflect heavy objects.

Reduced Toe Clearance

Pay attention to the space inside the boot. If the toe area feels like it is collapsing or if there is reduced toe clearance pressing against your foot, the structural dome is deforming.

Wear and Tear Assessment

Sole Degradation

The condition of the outsole is a primary safety feature. Check for excessive wear on the soles that smooths out the tread pattern.

Once the tread is gone, you lose traction, significantly increasing the risk of slips and falls in hazardous conditions.

Heel Instability

Examine the heel counter and the sole connection. Loose heels or uneven wear patterns on the heel indicate that the boot can no longer provide a stable platform for your foot.

This instability can lead to rolled ankles and long-term joint alignment issues.

Mechanical Failures

Inspect the fastening systems. While frayed laces or malfunctioning zippers can sometimes be repaired, they are often precursors to general boot failure.

If the boot cannot be secured tightly, it cannot offer the ankle support required for strenuous work.

The Role of Comfort and Support

Internal Support Breakdown

Comfort is not a luxury; it is a safety metric. If you notice a marked decrease in comfort or support, the internal midsole materials have likely compressed and failed.

Boots that no longer cushion impact contribute to fatigue, which directly correlates to a higher risk of workplace accidents.

Friction and Injury Risk

Worn-out boots often change shape, leading to rubbing and irritation.

If you begin developing blisters or hot spots in boots that were previously comfortable, the lining or internal structure has degraded to the point of needing replacement.

Understanding the Trade-offs

Repair vs. Replace

It is vital to distinguish between cosmetic damage and safety failures. Professional cobblers can often repair minor issues like broken zippers, frayed laces, or even re-sole certain high-end boots to extend their lifespan.

However, you must never attempt to repair the safety toe or the structural housing of the boot.

The Cost of Delaying Replacement

Trying to extend the life of a boot beyond the 6 to 12-month window in strenuous conditions is a false economy.

The trade-off for saving money on a new pair is often reduced slip resistance and compromised impact protection. In extreme weather or high-wear environments, failure can happen in as little as six months.

Making the Right Choice for Your Goal

If your primary focus is Maximum Safety: Replace your boots immediately after any heavy impact or if the steel cap becomes visible, regardless of the boot's age.

If your primary focus is Routine Maintenance: Inspect your boots monthly and plan for a full replacement every 6 to 12 months, or sooner if you work in extreme weather conditions.

If your primary focus is Long-Term Health: Retire boots the moment they show signs of uneven heel wear or internal cushion collapse to prevent fatigue and joint strain.

Your boots are your primary defense against workplace hazards; treat them as precision equipment, not just clothing.

Summary Table:

| Critical Sign | Why It Matters | Action Required |

|---|---|---|

| Exposed Toe Cap | Compromises structural integrity, reduces impact protection. | Replace Immediately. |

| Worn-Out Soles | Loss of traction, increases slip and fall risk. | Replace Immediately. |

| Loose Heels | Causes instability, leading to ankle injuries. | Replace Immediately. |

| Reduced Toe Clearance | Indicates internal structural failure. | Replace Immediately. |

| After Heavy Impact | Internal damage may be invisible but critical. | Replace Immediately. |

| Decreased Comfort/Support | Leads to fatigue and higher accident risk. | Plan for Replacement. |

Don't Compromise on Safety – Trust 3515 for Your Next Order

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial safety shoes and boots, built to the highest standards of durability and protection.

We provide:

- Reliable Quality: Durable construction designed to withstand demanding work environments.

- Certified Protection: Boots that meet or exceed industry safety standards.

- Bulk Supply Efficiency: Consistent quality and reliable delivery for your business.

Contact 3515 today to discuss your safety footwear needs and secure a trusted supply for your customers.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- What are the key features of a work boot? Essential Protection for Hazardous Work Environments

- What types of safety toe boots are available for different job requirements? Choose the Right Protection for Your Work

- What is the importance of choosing the right size for steel toe boots? Avoid Injury and Boost Productivity