The materials in a good safety shoe are a purpose-built system designed for protection, durability, and comfort. At its core, a quality shoe features a protective toe cap (often steel or a composite material), a puncture-resistant midsole made from materials like Kevlar or steel, and a durable outsole typically crafted from rubber or polyurethane. These components work together to shield the wearer from specific workplace hazards.

The best safety shoe isn't defined by a single superior material, but by the right combination of materials engineered to meet the specific hazards and comfort demands of your work environment.

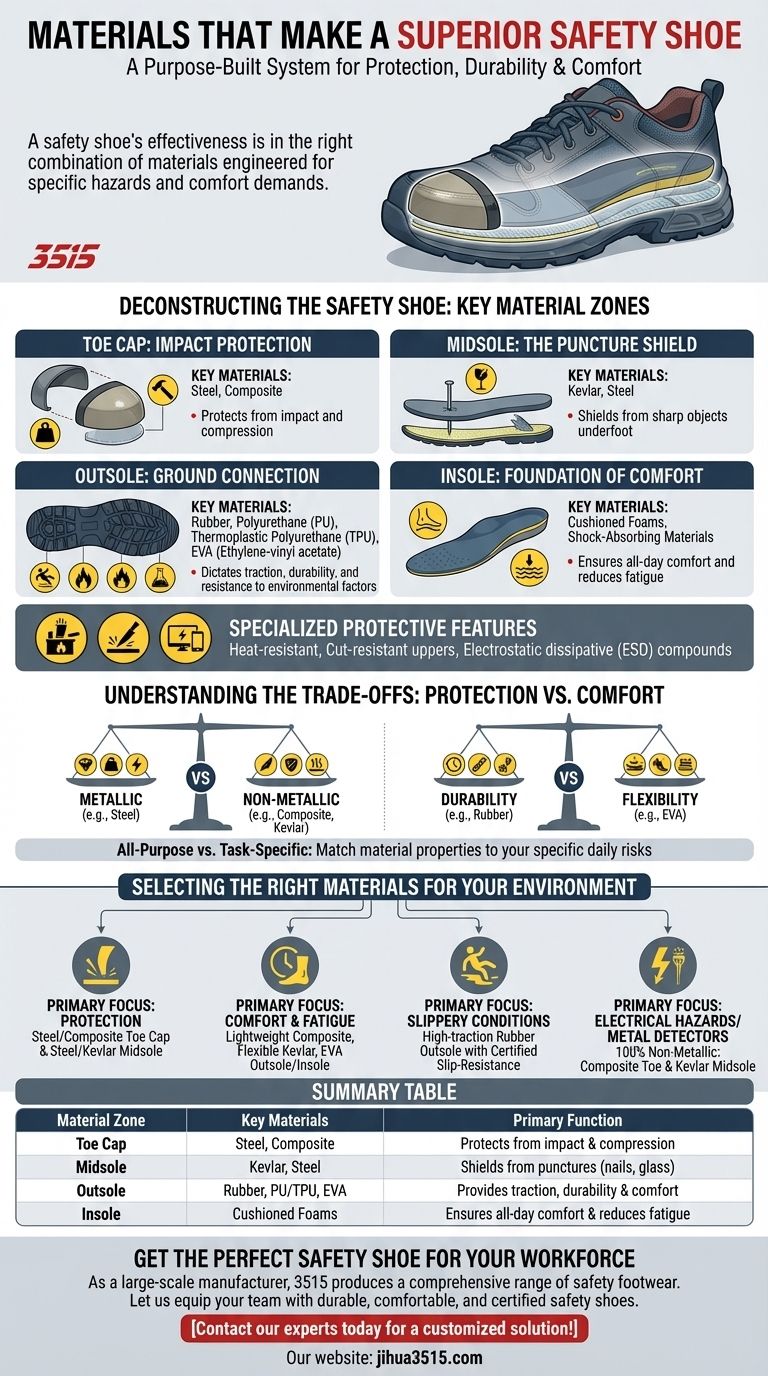

Deconstructing the Safety Shoe: Key Material Zones

To understand what makes a safety shoe effective, we must look at it as a series of functional zones, each with materials chosen for a specific task.

The Midsole: The Puncture Shield

The midsole provides critical protection from sharp objects underfoot, such as nails or glass.

Your two primary material choices are Kevlar and steel. Kevlar midsoles are lightweight, flexible, and non-metallic, enhancing comfort and making them ideal for environments with metal detectors. Steel offers maximum puncture resistance but adds weight and rigidity.

The Outsole: Your Connection to the Ground

The outsole dictates traction, durability, and resistance to environmental factors.

Common materials include rubber, which is valued for its excellent slip resistance and resistance to heat, acids, and alkalis. Polyurethane (PU) and Thermoplastic Polyurethane (TPU) offer a good balance of durability and lightness, while EVA (Ethylene-vinyl acetate) is extremely lightweight and provides excellent cushioning, similar to a running shoe.

The Insole: The Foundation of Comfort

The insole is the layer your foot directly contacts, and it is crucial for all-day comfort and support.

A high-quality insole should be made of soft, shock-absorbing materials to reduce fatigue. This is a non-negotiable feature, as comfort is essential for safety and productivity during long workdays.

Specialized Protective Features

Beyond the core components, specific jobs require materials with specialized properties.

These can include heat-resistant materials for foundry work, cut-resistant uppers for handling sharp materials, and specific compounds for electrostatic dissipative (ESD) properties to protect sensitive electronic equipment.

Understanding the Trade-offs: Protection vs. Comfort

Choosing the right materials always involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Metallic vs. Non-Metallic

Steel components offer robust protection but are heavier and conduct both temperature and electricity. Composite materials, including Kevlar and composite toe caps, are significantly lighter, do not conduct electricity, and won't get cold in winter, but may offer a slightly bulkier profile.

Durability vs. Flexibility

A thick, dense rubber outsole provides maximum longevity and resistance to chemicals but can feel stiff. An EVA outsole, common in "athletic-style" safety shoes, offers superior flexibility and cushioning but may wear down faster in abrasive environments.

All-Purpose vs. Task-Specific

A shoe designed for a single, extreme hazard (like a logger's boot with maximum cut resistance) may be less comfortable or practical for general warehouse work. The goal is to match the material's specific protective qualities to the actual, daily risks you face.

Selecting the Right Materials for Your Environment

Your choice should be guided by a clear understanding of your job's primary demands.

- If your primary focus is protection from punctures and impacts: Prioritize shoes with certified steel or composite toe caps and a steel or Kevlar midsole.

- If your primary focus is all-day comfort and preventing fatigue: Look for lightweight composite materials, flexible Kevlar midsoles, and cushioned EVA outsoles or insoles.

- If your primary focus is working in slippery or hazardous conditions: A high-traction rubber outsole with a certified slip-resistance rating is non-negotiable.

- If your primary focus is working around electrical hazards or metal detectors: Insist on a shoe with 100% non-metallic construction, including a composite toe and Kevlar midsole.

Ultimately, a well-chosen safety shoe is an essential piece of professional equipment that directly supports your ability to work safely and effectively.

Summary Table:

| Material Zone | Key Materials | Primary Function |

|---|---|---|

| Toe Cap | Steel, Composite | Protects from impact and compression |

| Midsole | Kevlar, Steel | Shields from punctures (nails, glass) |

| Outsole | Rubber, PU/TPU, EVA | Provides traction, durability, and comfort |

| Insole | Cushioned Foams | Ensures all-day comfort and reduces fatigue |

Get the Perfect Safety Shoe for Your Workforce

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, engineered with the right materials to meet your specific workplace hazards and comfort demands.

Let us help you equip your team with durable, comfortable, and certified safety shoes that enhance productivity and protection. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Why is investing in the right safety shoes important for workplace safety? Protect Your Team and Your Bottom Line

- How do surface patterns on rubber outsoles improve safety shoe performance? Master Traction with Advanced Engineering

- Why are safety shoes important in the construction sector? Essential Protection for Your Workforce

- What are the specific protective features of industrial-grade safety shoes? Engineering Safety for Construction Sites

- How does specialized protective footwear safeguard workers handling heavy railway iron shoes? Enhancing Safety & Stability

- What core protective functions do Industrial-grade Safety Shoes provide? Key Foot Protection for High-Risk Environments

- How does a bionic robot slip testing device contribute to the quality validation of safety shoes? Ensuring Unmatched Worker Safety

- Why wear protective masks, gloves, and safety shoes in 5S Shine? Elevate Safety and Discipline