When selecting a work boot sole, your decision must be guided by the specific demands of your work environment. The most critical considerations are the tread pattern for slip resistance, the presence of a defined heel for stability on ladders, and the material's properties, which dictate its resistance to hazards like extreme heat.

The sole of a work boot is not a single component, but an engineered system. Viewing it as the interface between you and your work surface is the key to making a decision that maximizes both safety and performance.

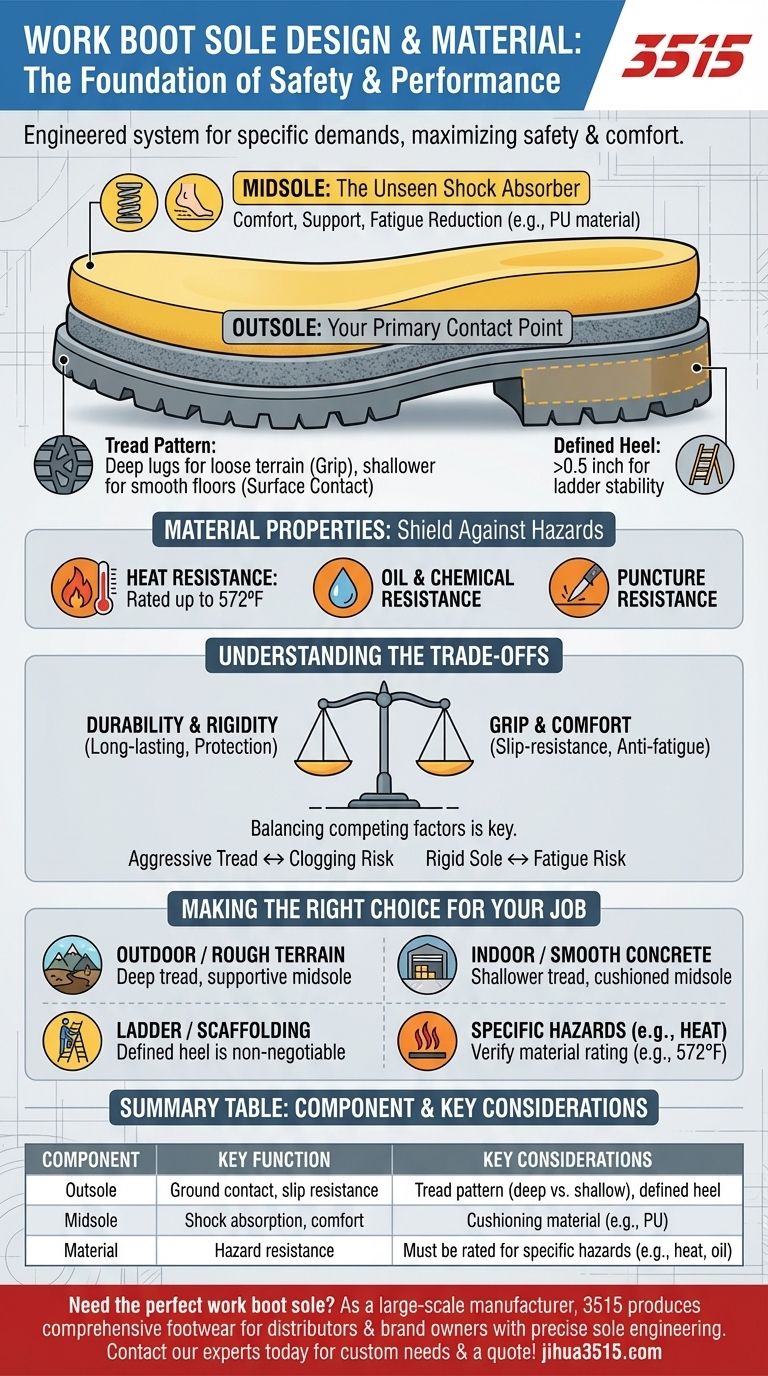

Deconstructing the Work Boot Sole

To make an informed choice, you must understand the distinct parts of the sole and their functions. Each element is designed to solve a specific problem.

The Outsole: Your Primary Point of Contact

The outsole is the layer that touches the ground. Its design directly impacts your stability and safety.

Key features include the tread pattern, which is your primary defense against slips. Deeper, more aggressive treads are essential for gripping loose or uneven surfaces like mud and gravel. Shallower patterns provide more surface contact, which is better for smooth concrete or indoor floors.

The heel is another critical design element. A defined heel (at least half an inch high) acts as a catch point, providing crucial stability when climbing ladders, scaffolding, or walking on gantries. In contrast, a smooth or wedge sole prevents snagging, a design principle seen in specialized footwear like riding boots.

The Midsole: The Unseen Shock Absorber

Located between the outsole and your foot, the midsole is responsible for comfort and support. Its primary job is shock absorption, reducing the fatigue that comes from standing or walking on hard surfaces all day.

Midsoles are often made from materials like polyurethane (PU), which provides a durable cushion against impact. This component is fundamental to a boot's long-term comfort and support.

Material Properties: The Shield Against Hazards

The material composition of the sole dictates its resistance to environmental threats. Heat resistance is a non-negotiable feature for those working on hot surfaces, such as road paving. A sole should be rated to withstand temperatures up to 572ºF in these environments.

Other material properties, though not always visible, include resistance to oil, chemicals, and punctures, which are vital in specific industrial settings.

Understanding the Trade-offs

Choosing the perfect sole always involves balancing competing factors. Understanding these trade-offs is the mark of a well-informed decision.

Durability vs. Grip

Harder rubber compounds are highly durable and resist abrasion, leading to a longer-lasting sole. However, they may offer less grip on smooth, wet surfaces. Softer compounds provide excellent slip resistance but will wear out more quickly.

Aggressive Treads vs. Clogging

Deep lugs are excellent for traction on soft ground but can become clogged with mud or debris. This not only reduces their effectiveness but can also lead to tracking dirt into finished areas or vehicles.

Rigidity vs. Comfort

A rigid, highly supportive sole is ideal for protecting your feet on sharp, uneven terrain. However, that same rigidity can feel stiff and fatiguing when worn for 10 hours on a flat warehouse floor. The midsole's cushioning helps mitigate this, but the balance is critical.

Making the Right Choice for Your Job

Your specific daily tasks should be the final authority in your decision. Use these guidelines to select a sole that is an asset, not a liability.

- If your primary focus is working outdoors on varied, rough terrain: Prioritize a sole with a deep, aggressive tread pattern for maximum grip and a supportive midsole for stability.

- If your primary focus is working indoors on smooth concrete: Look for a slip-resistant outsole with a shallower tread to maximize surface contact and a well-cushioned midsole to fight fatigue.

- If your primary focus involves frequent use of ladders or scaffolding: A sole with a well-defined heel is a non-negotiable safety requirement.

- If your primary focus exposes you to specific hazards like heat: You must verify that the sole's material is explicitly rated to withstand the temperatures or substances you encounter.

Ultimately, selecting the right sole is a critical investment in your personal protective equipment.

Summary Table:

| Component | Key Function | Key Considerations |

|---|---|---|

| Outsole | Ground contact, slip resistance | Tread pattern (deep vs. shallow), defined heel for ladders |

| Midsole | Shock absorption, comfort | Cushioning material (e.g., PU) for all-day support |

| Material | Hazard resistance (heat, oil, chemicals) | Must be rated for specific job hazards (e.g., heat up to 572°F) |

Need the perfect work boot sole for your specific job requirements?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise sole designs and materials discussed here. We can help you provide footwear that delivers maximum safety, durability, and comfort for your workforce.

Contact our experts today to discuss your custom work boot needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- How does a well-fitted fire boot prevent injuries? The Dual Defense System Explained

- How do versatile work shoes maintain a balance between protection and comfort? Unlock Efficiency in Mixed Environments

- How can proper care extend the lifespan of work boots? Maximize Durability & Safety

- What factors should firefighters consider when choosing footwear? A Guide to Safety & Fit

- How do the heels differ between cowboy boots and Western work boots? Choose the Right Heel for Your Job

- Why might OSHA or an employer require safety toe boots? Essential Protection for Hazardous Workplaces

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort

- What are the key features of heavy duty work boots? Your Guide to Superior Safety and Durability