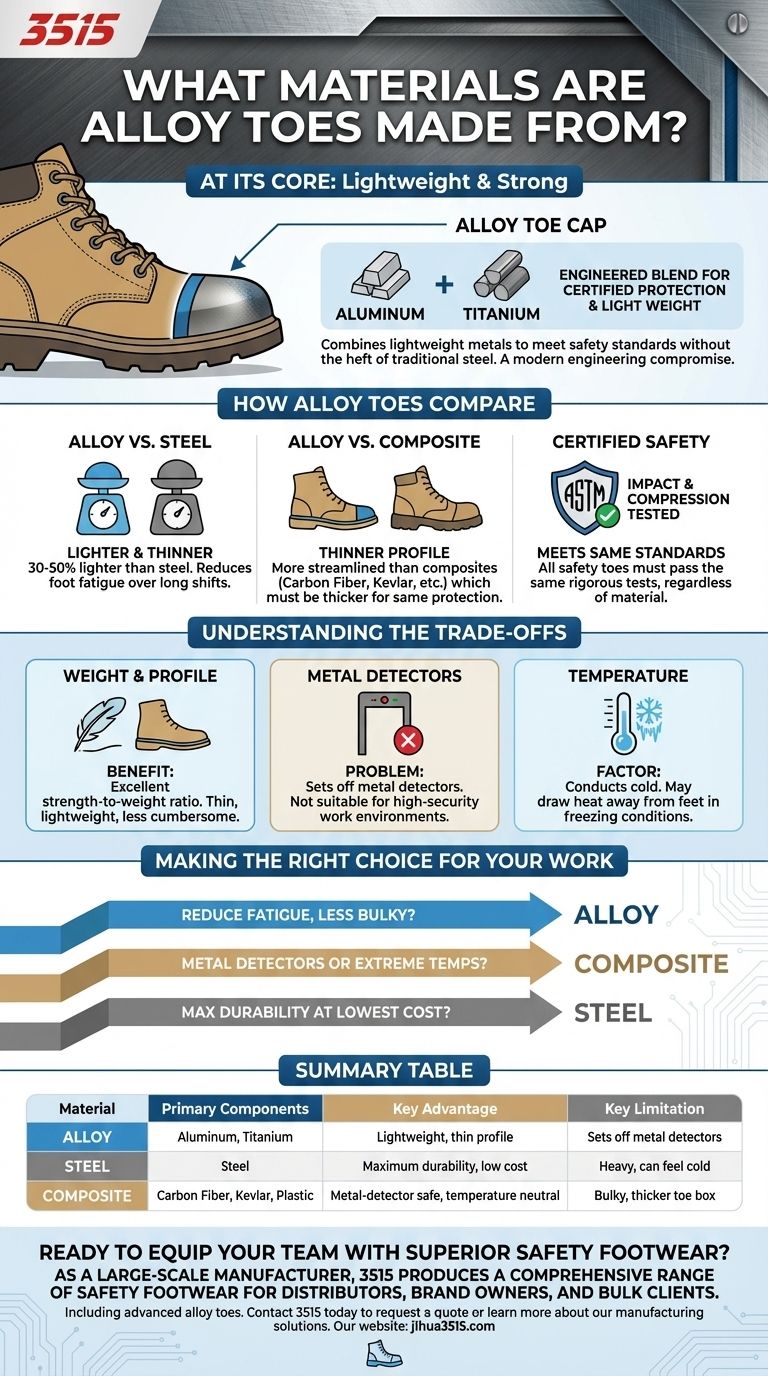

At its core, an alloy safety toe is constructed from a combination of lightweight yet strong metals. The most common materials used are aluminum and titanium, which are blended to create a protective cap that meets certified safety standards without the weight of traditional steel.

While steel has long been the standard, alloy toes represent an engineering compromise, offering comparable impact protection in a significantly lighter and often thinner package than other safety toe options.

How Alloy Toes Compare to Other Materials

To understand the value of an alloy toe, you must see it in context with the other primary types of safety footwear: steel and composite. All are designed to meet the same fundamental safety standards set by organizations like the ASTM (American Society for Testing and Materials).

Alloy vs. Steel

The primary advantage of alloy over steel is weight reduction. Alloy toes can be 30-50% lighter than their steel counterparts.

This decrease in weight directly translates to less foot fatigue over a long workday, a critical factor for anyone who spends hours on their feet.

Alloy vs. Composite

Composite toes are made from non-metal materials like carbon fiber, Kevlar, plastic, or fiberglass.

While composites are also lightweight, they must be thicker and bulkier than alloy or steel toes to provide the same level of impact protection. An alloy toe allows for a more streamlined, less bulbous toe box.

Meeting the Same Standard

It is crucial to understand that if a boot is rated for safety, its toe cap has passed the same tests for impact and compression, regardless of the material. The choice between them is not about which is "safer," but about which material's properties best suit your specific work environment and needs.

Understanding the Trade-offs

Choosing a safety toe involves balancing competing benefits. No single material is perfect for every situation.

The Weight and Profile Advantage

Alloy's key benefit is its excellent strength-to-weight ratio. This allows it to provide certified protection in a thin, lightweight cap, resulting in a more comfortable and less cumbersome boot.

The Metal Detector Problem

Like steel, an alloy toe cap will set off metal detectors. This makes it an unsuitable choice for workers who must frequently pass through security screenings, such as in airports, nuclear facilities, or certain government buildings.

The Temperature Factor

Metals are excellent conductors of temperature. In very cold environments, both steel and alloy toes can draw heat away from the feet, making them feel colder. Composite toes, being non-metallic, do not have this issue.

Making the Right Choice for Your Work

Selecting the correct safety toe is about matching the material's properties to the demands of your job.

- If your primary focus is reducing foot fatigue and you prefer a less bulky boot: Alloy is the ideal choice, offering a great balance of lightweight protection.

- If your primary focus is working around metal detectors or in extreme temperatures: A non-metallic composite toe is the superior option.

- If your primary focus is maximum durability at the lowest possible cost: Traditional steel remains an incredibly effective and economical solution.

Ultimately, understanding these material differences empowers you to choose footwear that works for you, not against you.

Summary Table:

| Material | Primary Components | Key Advantage | Key Limitation |

|---|---|---|---|

| Alloy | Aluminum, Titanium | Lightweight, thin profile | Sets off metal detectors |

| Steel | Steel | Maximum durability, low cost | Heavy, can feel cold |

| Composite | Carbon Fiber, Kevlar, Plastic | Metal-detector safe, temperature neutral | Bulky, thicker toe box |

Ready to Equip Your Team with Superior Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including those with advanced alloy toes.

We provide the durable, comfortable, and certified protective footwear your customers need. Let's discuss how we can support your business.

Contact 3515 today to request a quote or learn more about our manufacturing solutions.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Lightweight Cushioned Athletic Sneakers for Custom Bulk Production

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- Why is an Inertial Measurement Unit (IMU) integrated into smart assistive footwear? Unlocking Precision Navigation

- What are the characteristics of Oxford work shoes? A Guide to Professional Footwear

- What is the significance of Functional Reach Test (FRT) benchmarks for balance risks in heavy boots and safety gear?

- Why is protective footwear important in heavy work environments? A Complete Guide to Worker Safety

- What are the primary injury prevention benefits of using impact-resistant safety footwear in high-risk metal processing zones?

- What is the physiological importance of high-density shock-absorbing midsoles? Protect Workers' Cardiovascular Health

- What is an OSHA approved shoe? The Truth About Compliant Safety Footwear

- What role does professional supervision play in increasing the compliance of wearing Safety Shoes and protective gear?