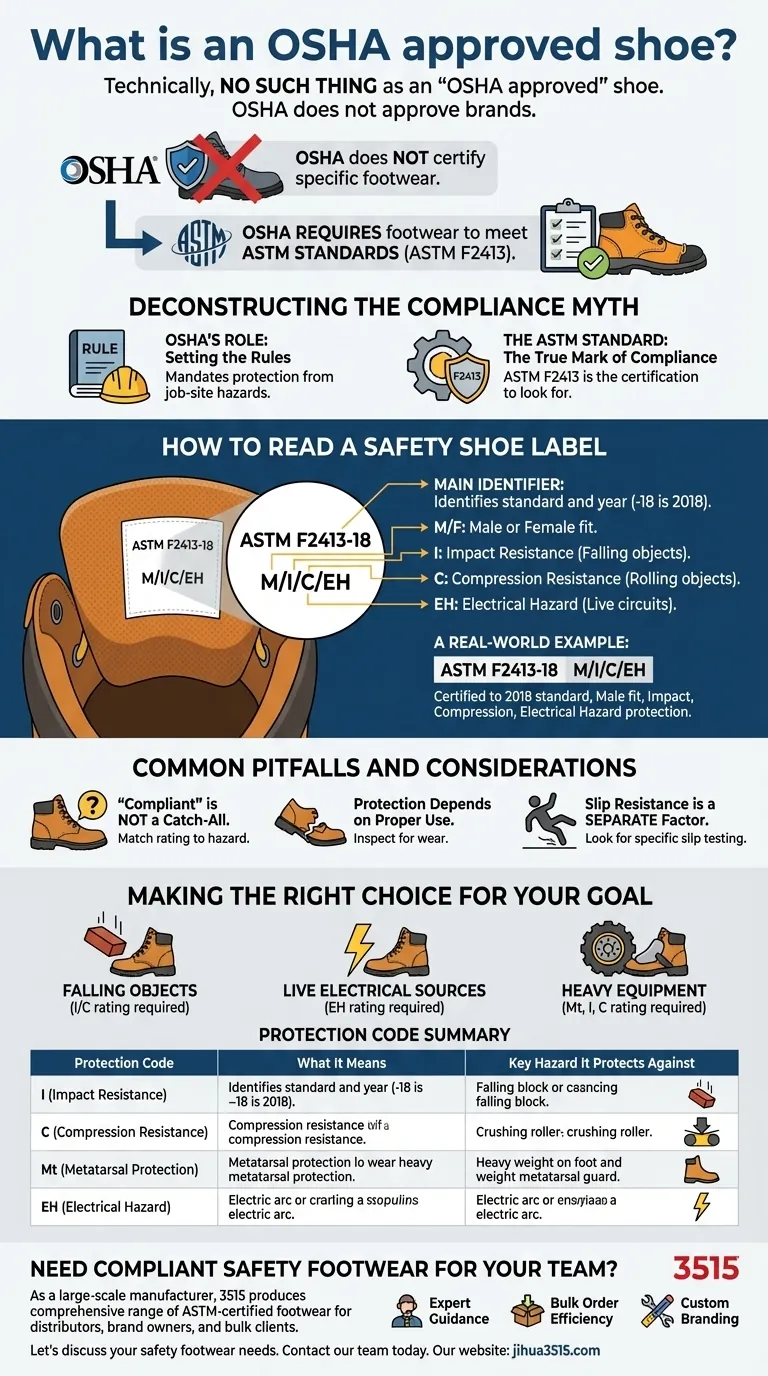

Technically, there is no such thing as an "OSHA approved" shoe. The Occupational Safety and Health Administration (OSHA) does not directly test, certify, or approve specific brands or models of footwear. Instead, OSHA requires employers to ensure their workers use protective footwear that meets or exceeds standards developed by organizations like the American Society for Testing and Materials (ASTM).

The search for an "OSHA approved" shoe is really a search for footwear that is certified to meet specific ASTM safety standards. You can verify this compliance by learning to read the code printed on the shoe's label.

Deconstructing the Compliance Myth

OSHA's Role: Setting the Rules

OSHA's mission is to ensure safe working conditions. Part of this involves setting requirements for Personal Protective Equipment (PPE), including footwear.

Their regulations mandate that workers must be protected from job-site hazards like falling objects, punctures, and electrical dangers.

The ASTM Standard: The True Mark of Compliance

The specific standard for safety footwear in the United States is ASTM F2413. This is the certification you should look for.

When a shoe is labeled with "ASTM F2413," it means it has been tested and certified to meet the minimum performance requirements for protective footwear.

How to Read a Safety Shoe Label

The key to choosing the right footwear is understanding the specific, indelible markings required by the ASTM standard, which are typically found on the shoe's tongue.

The Main Identifier

The first line of the label will always identify the ASTM standard it meets, such as ASTM F2413-18. The "-18" simply indicates the year the standard was updated (2018).

Decoding the Protection Line

The second line of the label contains a series of codes that tell you exactly what hazards the shoe protects against.

- M/F: Indicates whether the shoe is designed for a Male or Female fit.

- I: Stands for Impact Resistance. This confirms the toe box protects against falling objects.

- C: Stands for Compression Resistance. This means the toe box protects against rolling objects or compression.

- Mt: Indicates Metatarsal Protection. This feature adds a guard to protect the top of the foot.

- EH: Signifies Electrical Hazard protection. These shoes are designed to reduce the potential for electric shock from live circuits.

A Real-World Example

A label might read:

ASTM F2413-18

M/I/C/EH

This tells you the shoe was certified to the 2018 standard, is for a male, and provides Impact, Compression, and Electrical Hazard protection.

Common Pitfalls and Considerations

"Compliant" is Not a Catch-All

A shoe can be compliant with the ASTM standard but still be the wrong shoe for your specific job.

For example, a shoe rated for EH is essential for an electrician but offers no specific benefit on a construction site where puncture resistance is the primary concern. Always match the shoe's specific ratings to the hazards you face.

Protection Depends on Proper Use

Even a perfectly rated shoe is ineffective if it's damaged or fits poorly. Regularly inspect your footwear for wear and tear, as cracks or excessive wear can compromise its protective features.

Slip Resistance is a Separate Factor

While many safety shoes are slip-resistant, this is not a required component of the core ASTM F2413 standard. If you work on wet or slick surfaces, ensure you are also looking for footwear specifically tested for slip resistance.

Making the Right Choice for Your Goal

To ensure you have the right protection, identify your primary workplace hazard and select footwear with the corresponding rating.

- If your primary focus is protection from falling objects: Your shoe must be rated for Impact (

I) and Compression (C). - If your primary focus is working near live electrical sources: You must select a shoe with an Electrical Hazard (

EH) rating. - If your primary focus is safeguarding against heavy equipment: Look for Metatarsal (

Mt) protection in addition to standardIandCratings.

Ultimately, choosing the right safety shoe is about understanding your environment's risks and matching them to the specific protections certified on the shoe's label.

Summary Table:

| Protection Code | What It Means | Key Hazard It Protects Against |

|---|---|---|

| I | Impact Resistance | Falling objects |

| C | Compression Resistance | Rolling or crushing objects |

| Mt | Metatarsal Protection | Heavy impacts to the top of the foot |

| EH | Electrical Hazard | Live electrical circuits |

Need Compliant Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring your workforce has the precise protection they need.

We provide:

- Expert Guidance: Match the right ASTM ratings to your specific job-site hazards.

- Bulk Order Efficiency: Streamlined sourcing for large-volume requirements.

- Custom Branding: Private label options for brand owners and distributors.

Let's discuss your safety footwear needs. Contact our team today for a consultation.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time