The recommended method for removing rubber boots is to use a boot jack. This simple tool allows you to remove boots in a single, fluid motion without bending over or using your hands, which keeps you clean and prevents damage to the boot itself.

The core challenge with rubber boots is removing them cleanly and without causing long-term damage. The standard solution is a boot jack, which protects the boot's structure, minimizes physical strain, and prevents the transfer of mud and dirt.

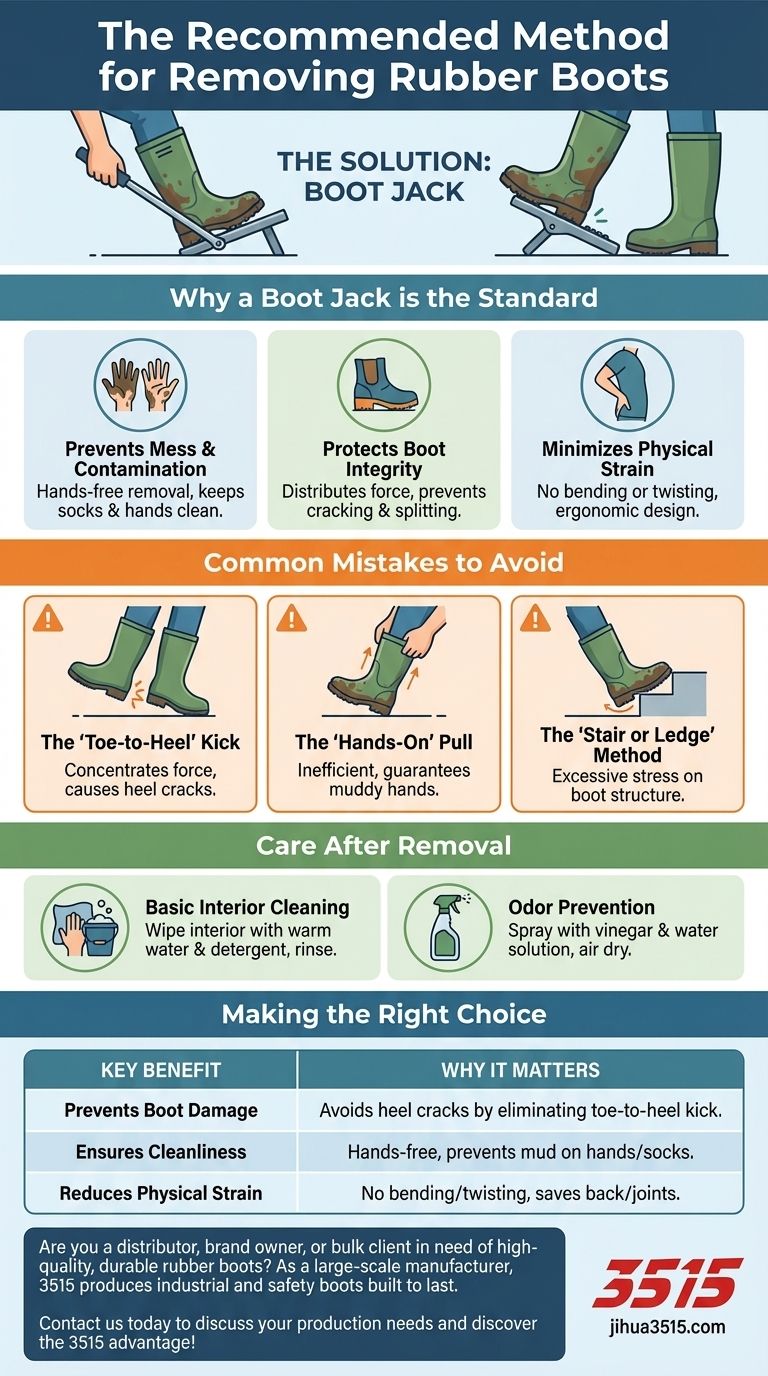

Why a Boot Jack is the Standard Method

A boot jack is a Y-shaped tool that provides leverage to remove boots effortlessly. It is considered the best practice for several key reasons.

It Prevents Mess and Contamination

Using a boot jack means you do not have to touch a muddy boot with your hands.

This also prevents you from getting your socks dirty by trying to kick the boot off with your other foot. It's a cleaner, more efficient process.

It Protects the Boot's Integrity

The most common way people damage their boots is by repeatedly pushing on the heel with their other foot. This action puts immense stress on the heel counter.

Over time, this focused pressure can cause the rubber to weaken, crack, and split, significantly shortening the lifespan of your boots. A boot jack distributes the force evenly and safely.

It Minimizes Physical Strain

Bending and twisting to pull off a tight-fitting boot can put unnecessary strain on your back and joints.

A boot jack allows you to remain upright, using simple leverage to slide your foot out with minimal effort.

Common Mistakes to Avoid

Without a proper tool, people resort to methods that can cause damage to their gear or themselves. Understanding these pitfalls highlights the value of the correct technique.

The 'Toe-to-Heel' Kick

This is the most frequent mistake. Prying one boot off with the toe of the other concentrates all the force on a single point on the heel, leading directly to cracks and splits over time.

The 'Hands-On' Pull

Grabbing the boot and yanking it off is not only strenuous but also guarantees muddy hands. This is inefficient and messy, defeating the purpose of wearing protective footwear in the first place.

The 'Stair or Ledge' Method

Using a stair, curb, or trailer hitch to hook the heel and pull your foot out causes the same concentrated damage as the toe-to-heel kick. It puts excessive stress on the boot's construction.

A Note on Care After Removal

Proper removal is the first step in boot maintenance. Once they are off, a quick cleaning ensures they are ready for their next use.

Basic Interior Cleaning

To clean the inside, mix one teaspoon of heavy-duty laundry detergent with two cups of warm water. Wipe the interior with a cloth dampened with this solution.

Follow up by wiping it down again with a second cloth soaked in only warm water to rinse away any soap residue.

Odor Prevention

For persistent odors, you can spray the inside of the boots with a simple solution of equal parts white vinegar and water. Allow them to air dry completely.

Making the Right Choice for Your Goal

Adopting the right technique is simple and has immediate benefits for both you and your equipment.

- If your primary focus is preserving your gear: Use a boot jack to avoid putting stress on the heel, which is the most common cause of splitting.

- If your primary focus is cleanliness and convenience: A boot jack allows for hands-free removal in one motion, preventing muddy hands and socks.

- If your primary focus is avoiding physical strain: Using a boot jack eliminates the need to bend, twist, or pull, making it the easiest and most ergonomic option.

Ultimately, using a boot jack is the definitive method for maintaining your boots and making your daily routine easier.

Summary Table:

| Key Benefit | Why It Matters |

|---|---|

| Prevents Boot Damage | Avoids cracking the heel by eliminating the 'toe-to-heel' kick method. |

| Ensures Cleanliness | Hands-free removal prevents mud and dirt from getting on your hands and socks. |

| Reduces Physical Strain | No bending or twisting required, minimizing strain on your back and joints. |

Are you a distributor, brand owner, or bulk client in need of high-quality, durable rubber boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear built to last. Our production capabilities encompass all types of industrial and safety boots, designed with durability and user experience in mind. Let us help you supply your customers with reliable footwear that stands up to the toughest conditions.

Contact us today to discuss your production needs and discover the 3515 advantage!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How should wellies fit for optimal comfort? The Ultimate Guide to a Perfect Fit

- What type of socks should children wear with wellies to keep feet warm? Choose Wool or Thermal Materials

- Does the lining of Wellington boots affect the sizing? A Guide to Getting the Perfect Fit

- What finishing touches are applied to gumboots before packaging? Ensure Quality and Durability

- How do muck boots differ from traditional Wellingtons? Choose the Right Footwear for Your Outdoor Work

- What should be considered when choosing the right size of wellies for a child? A Guide to Perfect Fit & Comfort

- How does the tread design of PVC boots enhance functionality? Boost Safety and Comfort for Your Workforce

- Why should Wellington boots be stored upside down? Extend Boot Life with Proper Care