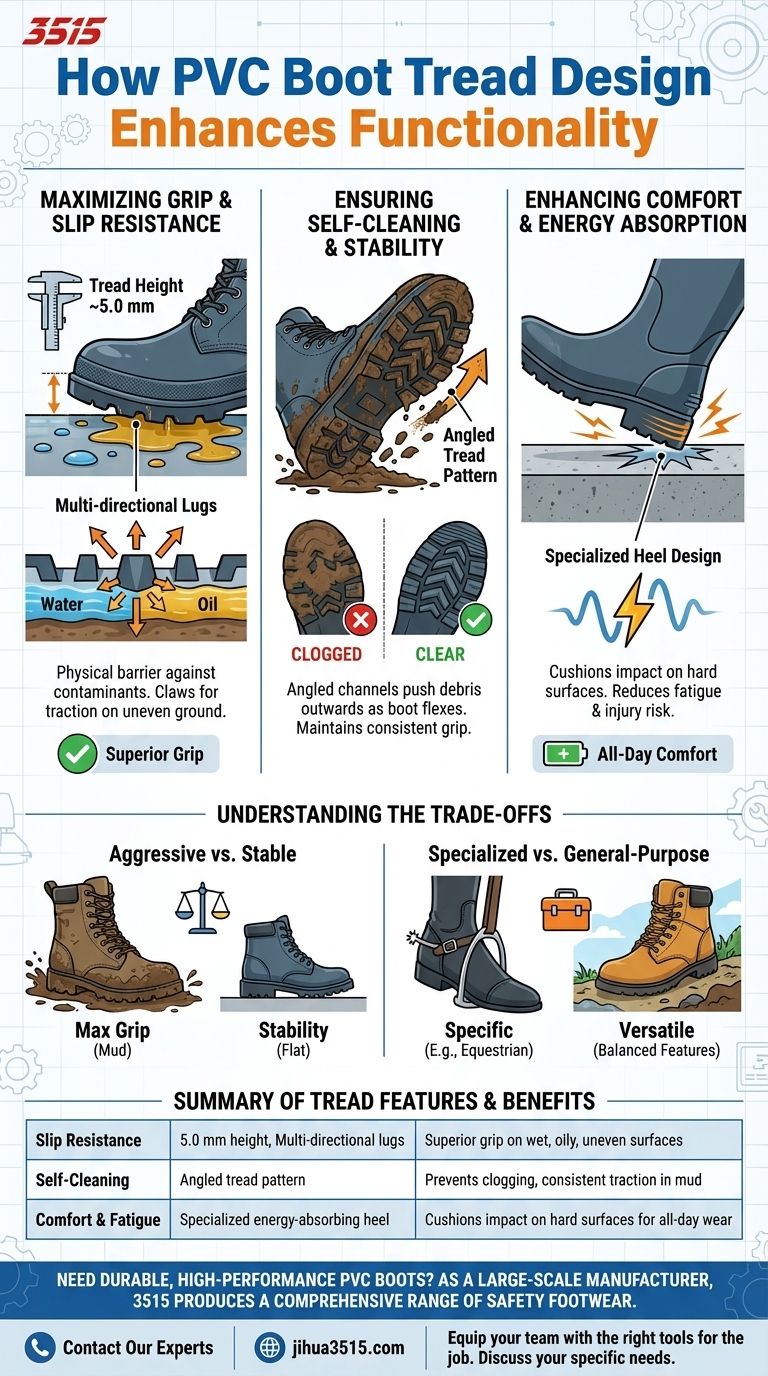

At its core, the tread design of a PVC boot enhances functionality through three critical mechanisms: providing slip resistance, ensuring self-cleaning to maintain grip, and absorbing energy to reduce wearer fatigue. Each element is engineered to maximize safety and efficiency in specific working conditions.

The effectiveness of a PVC boot is not just in its material, but in its purpose-built tread system. Understanding the interplay between tread depth, pattern, and heel design allows you to select a boot that performs as a reliable tool for your specific environment.

The Core Principles of Tread Design

A boot's sole is an engineered system. Every feature, from the depth of the grooves to the angle of the lugs, serves a distinct functional purpose.

Maximizing Grip and Slip Resistance

The most critical function of any boot tread is to prevent slips and falls, particularly on hazardous surfaces.

A specific tread height, often around 5.0 mm, is engineered to create a physical barrier against slippery contaminants. This depth allows the tread to cut through water, oil, and grease to make solid contact with the ground underneath.

Deep, multi-directional grooves, or lugs, act like claws, providing superior traction on uneven and loose surfaces like mud or gravel.

Ensuring Self-Cleaning and Stability

Consistent grip is impossible if the tread becomes clogged with dirt, mud, or debris.

An angled tread pattern is a key design feature that promotes self-cleaning. As the boot flexes during walking, the angled channels naturally push mud and dirt outwards, ensuring the lugs remain clear to maintain effective traction.

This prevents the sole from becoming a single, flat, and slippery surface, which is a common point of failure in boots with poor tread design.

Enhancing Comfort Through Energy Absorption

Functionality extends beyond just grip; it also includes the wearer's endurance and safety over a long day.

Many high-quality PVC boots incorporate a specialized heel design engineered for energy absorption. This feature cushions the impact of each step, particularly on hard surfaces like concrete.

By reducing the shock transmitted up through the leg and spine, this design significantly decreases fatigue and the risk of strain-related injuries over time.

Understanding the Trade-offs

No single tread design is perfect for every situation. The features that make a boot excel in one environment can be a liability in another.

Aggressive vs. Stable Treads

A boot with very deep, widely-spaced lugs is excellent for deep mud, as it provides maximum grip and self-cleaning. However, those same tall lugs can feel unstable on a hard, flat factory floor.

Conversely, a boot with a lower-profile, denser pattern provides more surface contact and stability on flat, wet surfaces but will quickly clog and fail in muddy conditions.

Specialized vs. General-Purpose Designs

Some designs are highly specialized. For example, an equestrian boot has a smooth sole and a distinct heel specifically to provide security in a stirrup, making it unsuitable for hiking.

Recognizing the intended application is crucial. A general-purpose boot offers a balance of features, but a specialized boot will always outperform it in its target environment.

Making the Right Choice for Your Goal

To select the right boot, you must match the tread's features to your primary operational need.

- If your primary focus is safety on wet or greasy indoor surfaces: Prioritize a boot with a documented tread depth (like 5.0 mm) and a high-contact pattern for maximum slip resistance.

- If your primary focus is stability on muddy or uneven outdoor terrain: Look for a design with deep, angled, and multi-directional lugs that emphasize self-cleaning.

- If your primary focus is all-day comfort and reduced fatigue: Ensure the boot specifies an energy-absorbing heel design to cushion impact on hard ground.

Choosing the right PVC boot is about selecting the right tool for the job.

Summary Table:

| Function | Key Tread Feature | Primary Benefit |

|---|---|---|

| Slip Resistance | 5.0 mm tread height, multi-directional lugs | Superior grip on wet, oily, and uneven surfaces |

| Self-Cleaning | Angled tread pattern | Prevents clogging, maintains consistent traction in mud/debris |

| Comfort & Fatigue Reduction | Specialized energy-absorbing heel | Cushions impact on hard surfaces for all-day wear |

Need Durable, High-Performance PVC Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of PVC boots and work shoes, engineered with the precise tread designs detailed above to ensure maximum safety, durability, and comfort for your workforce.

Let us help you equip your team with the right tools for the job. Contact our experts today to discuss your specific needs and discover how we can become your trusted footwear manufacturing partner.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are some key certifications or standards for sustainable wellies? Verify Eco-Friendly & Ethical Footwear

- Is it advisable to manually stretch children's wellies? Protect Your Child's Foot Health and Boot Integrity

- What is the role of a plasticizer in PVC rain boot production? Achieve the Perfect Flexibility and Durability

- What additional features do some wellington boots have to enhance comfort and warmth? Discover Advanced Insulation & Support

- What additional feature in wellies can enhance warmth? Choose the Right Lining for Ultimate Comfort

- Do Wellington boots require a breaking-in period? No, but here's how to ensure immediate comfort.

- Why are rain boots a good option for gardening? Stay Dry and Protected in Any Weather

- What are the recommended materials for temporary or part-time workers needing waterproof boots? Find the Most Cost-Effective Choice