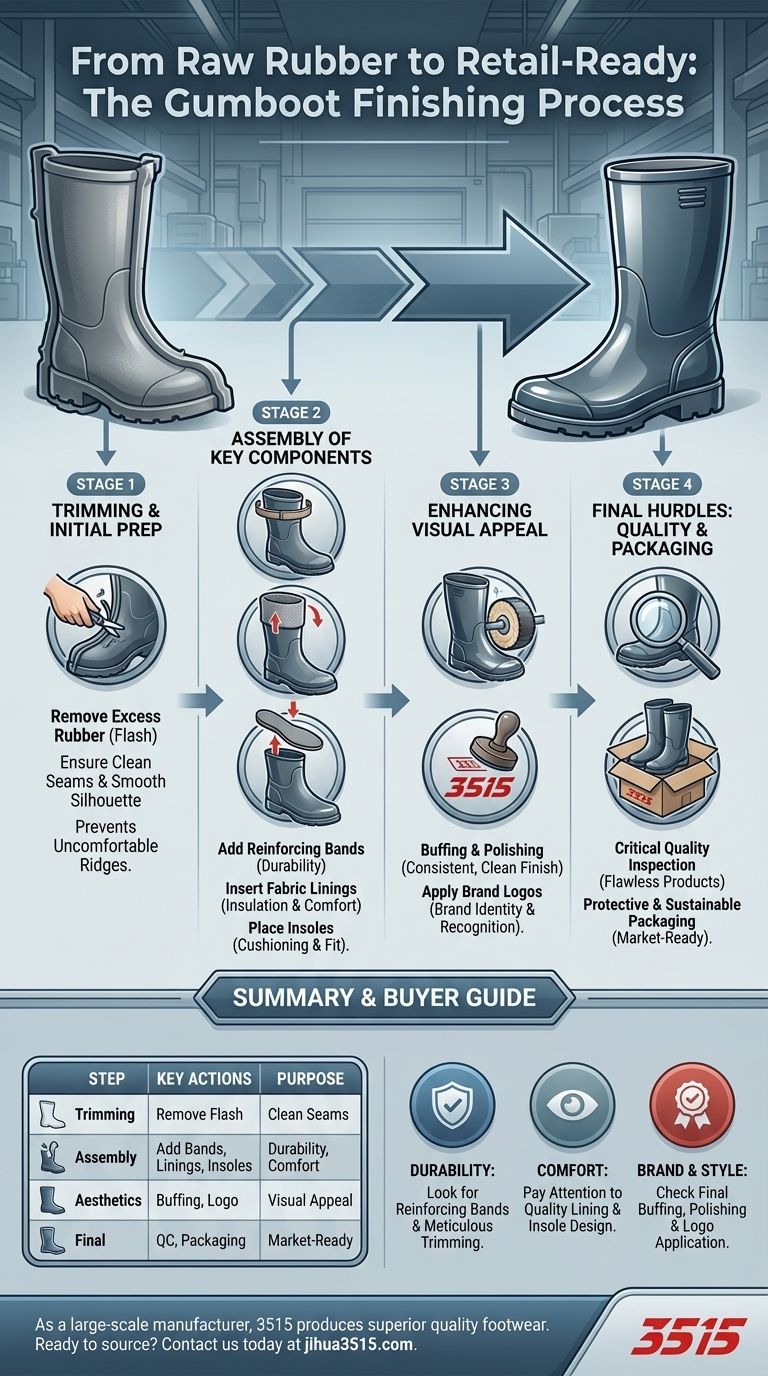

The final touches applied to gumboots before they are ready for the market include polishing, buffing, adding components like insoles and linings, and applying branding such as logos. These steps transform the rough, molded rubber into a finished product, ensuring it meets quality standards for appearance, comfort, and durability.

The core takeaway is that "finishing" gumboots is not a single action but a multi-step process. It bridges the gap from raw manufacturing to a retail-ready product by adding crucial components, enhancing visual appeal, and performing final quality checks.

From Raw Mold to Finished Product

The finishing stage is where a basic rubber shell becomes a functional and marketable gumboot. This process can be broken down into several distinct phases, each serving a specific purpose.

Trimming and Initial Preparation

The first step after the boot comes out of its mold is to remove any imperfections left from the manufacturing process.

Excess rubber, known as "flash," is carefully trimmed from the seams. This ensures a clean, smooth silhouette and prevents uncomfortable ridges.

Assembly of Key Components

Once trimmed, the boot is assembled with several components that are critical for performance and comfort.

Reinforcing bands may be added around the top or other high-stress areas to improve strength and longevity.

Fabric linings are inserted to provide insulation and comfort, preventing the rubber from chafing against the skin.

Insoles are placed inside the boot to offer cushioning, arch support, and a better overall fit for the wearer.

Enhancing Visual Appeal

With the structural components in place, the focus shifts to aesthetics and branding.

Buffing and polishing the exterior rubber surface gives the gumboots a consistent, clean finish and enhances their visual appeal.

Brand logos and other decorative details are applied. This is a crucial step for brand identity and market recognition.

The Final Hurdles: Quality Control and Packaging

Before a gumboot can be shipped, it must pass a final inspection and be packaged correctly. This ensures the customer receives a flawless product.

The Critical Quality Inspection

Each boot is thoroughly inspected for any defects. This includes checking for flaws in the rubber, ensuring all components are attached securely, and verifying that the final appearance meets brand standards.

Protective and Sustainable Packaging

Finally, the gumboots are packaged. Modern packaging uses materials designed to protect the boots during shipping and storage while also considering environmental sustainability.

Making the Right Choice for Your Needs

Understanding these finishing steps helps clarify what differentiates various gumboots on the market.

- If your primary focus is durability: Look for features like reinforcing bands and meticulous trimming, which indicate a focus on structural integrity.

- If your primary focus is comfort: Pay attention to the quality of the fabric lining and the design of the insole, as these components directly impact wearability.

- If your primary focus is brand and style: The quality of the final buffing, polishing, and logo application will be key indicators of a premium product.

Ultimately, a well-finished gumboot is the result of careful attention to detail at every stage, from assembly to final polish.

Summary Table:

| Finishing Step | Key Actions | Purpose |

|---|---|---|

| Trimming & Prep | Remove excess rubber (flash) | Ensure clean seams and comfort |

| Assembly | Add reinforcing bands, linings, insoles | Enhance durability, insulation, and comfort |

| Aesthetics | Buffing, polishing, logo application | Improve visual appeal and brand identity |

| Final Steps | Quality inspection, packaging | Guarantee flawless, market-ready products |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including gumboots with meticulous finishing touches for superior quality and comfort.

Ready to source durable, well-finished gumboots? Contact us today to discuss your specific needs and benefit from our expertise in delivering market-ready footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- What are the benefits of the waterproof feature in PVC boots? Keep Feet Dry & Protected in Any Condition

- Why are wellington boots particularly suitable for children? Unlock All-Weather Play & Development

- What are the disadvantages of Wellington boots? Key Downsides in Ergonomics and Comfort

- What are the characteristics of rain boots? A Guide to Waterproof Footwear for Every Need

- What are the advantages of rubber boots for deer hunting in terms of scent control? Master Stealth with Scent-Proof Footwear

- Are rubber rain boots a viable option for snake protection? Weighing Protection vs. Risk

- Are Wellington boots suitable for long walks? The Key Features for All-Day Comfort

- What is PVC and how is it used in rubber boots? A Guide to Waterproof & Affordable Footwear