In footwear manufacturing, Teflon coating on an outsole mold serves two primary, interconnected purposes. It functions as a superior non-stick surface for easy release of the cured rubber, and it provides a durable protective layer that preserves the mold's intricate details over thousands of production cycles.

The use of Teflon is not merely for convenience; it is a critical process that directly enhances production speed, minimizes product defects, and significantly extends the operational lifespan of the expensive mold tooling.

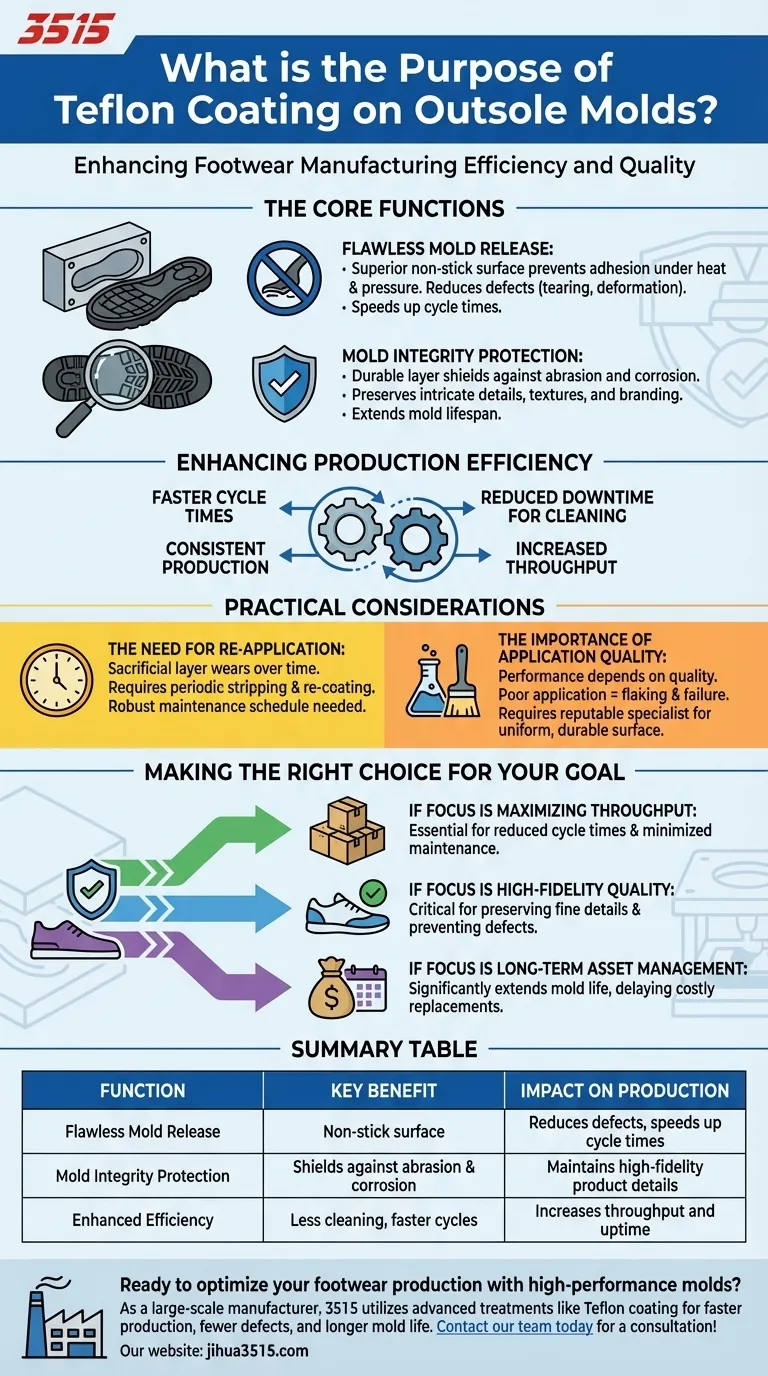

The Core Functions of Teflon Coating

To understand the value of this coating, it's essential to break down its impact on the manufacturing process, from material interaction to final product quality.

Facilitating Flawless Mold Release

Under the intense heat and pressure of vulcanization, raw rubber compounds become highly adhesive. Without a proper release agent, the finished outsole can stick to the metal mold.

This adhesion can cause the outsole to tear or deform during removal, resulting in a scrapped product. Teflon's extremely low coefficient of friction creates a non-stick barrier, ensuring a clean and effortless release every time.

Preserving Mold Integrity and Detail

Outsole molds are precision-engineered tools, often featuring complex tread patterns, textures, and logos that define a shoe's performance and brand identity.

The Teflon coating acts as a protective shield. It guards the mold's surface against the abrasive nature of rubber compounds and the corrosive effects of high-temperature processing, preventing wear and tear that would otherwise degrade fine details.

Enhancing Production Efficiency

Clean mold release directly translates to faster production cycle times. Operators can remove parts quickly and consistently without struggling with stuck components.

Furthermore, because less rubber residue is left behind, the need for frequent and time-consuming mold cleaning is drastically reduced. This increases the mold's overall uptime and factory throughput.

Understanding the Practical Considerations

While highly beneficial, implementing Teflon coating is a technical decision with its own set of operational factors to manage.

The Need for Re-application

The coating is a sacrificial layer that wears down over time due to the abrasive flow of rubber and repeated heat cycles.

Molds must be periodically taken out of production to be stripped and re-coated. This requires a robust maintenance schedule to avoid unexpected downtime.

The Importance of Application Quality

The performance of the coating is entirely dependent on the quality of its application.

A poorly applied coat can flake, fail prematurely, or provide an inconsistent finish, negating its benefits. Sourcing this work from a reputable specialist is critical to ensuring a uniform, well-bonded, and durable surface.

Making the Right Choice for Your Goal

Ultimately, the decision to use Teflon coating aligns with specific production priorities.

- If your primary focus is maximizing throughput: This coating is essential for reducing cycle times and minimizing downtime for mold cleaning and maintenance.

- If your primary focus is high-fidelity product quality: The protective layer is critical for preserving the fine textures and sharp branding details of your mold, preventing defects and ensuring consistency across every unit.

- If your primary focus is long-term asset management: The coating significantly extends the expensive mold's usable life, providing a clear return on investment by delaying the need for costly replacements.

Properly applied, Teflon coating transforms an outsole mold from a simple tool into a highly reliable and efficient production asset.

Summary Table:

| Function | Key Benefit | Impact on Production |

|---|---|---|

| Flawless Mold Release | Non-stick surface | Reduces defects, speeds up cycle times |

| Mold Integrity Protection | Shields against abrasion & corrosion | Maintains high-fidelity product details |

| Enhanced Efficiency | Less cleaning, faster cycles | Increases throughput and uptime |

Ready to optimize your footwear production with high-performance molds?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise includes utilizing advanced mold treatments like Teflon coating to ensure your production runs faster, with fewer defects and a longer-lasting mold life.

Let's discuss how we can apply this technology to your next project. Contact our team today for a consultation!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear