In cowboy boot construction, cementing the uppers to the linings is a foundational step that provides structural strength and, most critically, makes the boot's unique inside-out assembly possible. It effectively turns the separate leather upper and thin lining into a single, unified panel that can be precisely stitched and seamed.

The core purpose of cementing is not merely adhesion; it is a manufacturing necessity that enables the entire inside-out construction method specific to traditional cowboy boots, a process that would be virtually impossible with a loose, shifting lining.

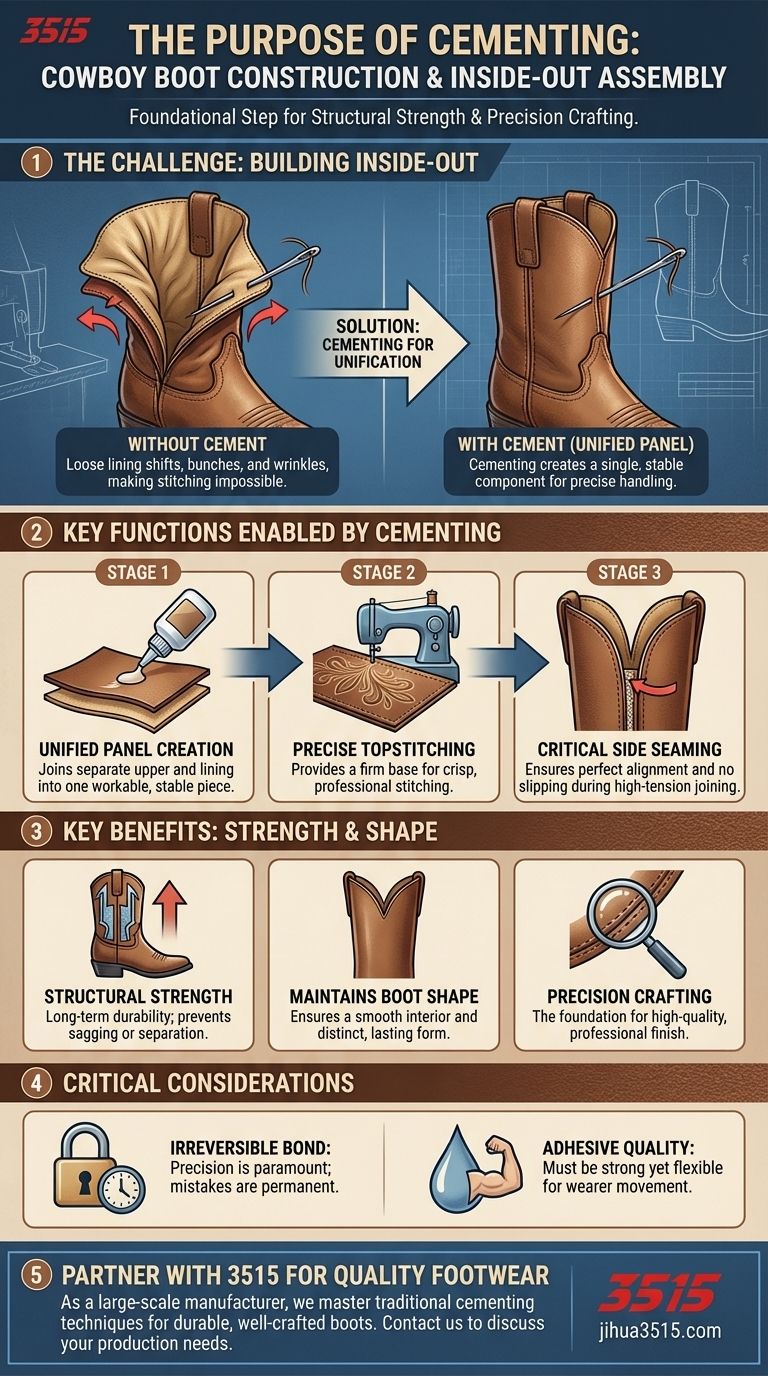

The Challenge: Building a Boot Inside-Out

To understand the role of cementing, you must first understand how a cowboy boot is fundamentally built. Unlike many other footwear types, it is assembled from two primary pieces (a front and a back) while inside-out.

Why Uncemented Linings Fail

If the lining were not glued to the upper, it would be a loose, separate piece of material. During the stitching of the side seams and decorative topstitching, this loose lining would inevitably bunch, wrinkle, and shift, leading to a flawed and structurally weak boot.

Creating a Unified, Workable Panel

Cementing the lining to the entire surface of the upper leather solves this problem. It creates a single, stable component that behaves as one piece of material, allowing the bootmaker to handle it with precision.

Key Functions Enabled by Cementing

This unified panel is what allows for the subsequent critical steps in the bootmaking process. The cement is the unseen enabler of the boot's final form and function.

Enabling Precise Topstitching

The decorative stitching on a cowboy boot shaft is intricate. A cemented lining provides a stable and firm base, ensuring the needle passes through both layers cleanly, resulting in crisp, professional stitch work without puckering.

Facilitating Critical Side Seaming

The most crucial step is joining the front and back halves of the boot. The side seams, which often include a welt for added strength, must perfectly capture both the upper and the lining. Cementing ensures these layers are perfectly aligned and cannot slip during this high-tension sewing operation.

Providing Foundational Structural Strength

The adhesive bond contributes significantly to the boot's long-term structure. It prevents the lining from sagging or separating from the upper over time, ensuring a smooth interior and helping the boot maintain its distinct shape.

Understanding the Implications of Cementing

While essential, the cementing process has direct consequences for the boot's construction and character. It is a decision that defines the manufacturing path.

The Irreversibility of the Bond

Once the upper and lining are cemented, they are permanently joined. This makes precision during the initial alignment paramount, as mistakes are difficult or impossible to correct without damaging the leather.

The Importance of Adhesive Quality

The type and application of the cement are critical. A poor-quality adhesive could fail over time, while too much adhesive could make the boot unnecessarily stiff. The goal is a bond that is strong yet flexible enough to move with the wearer's foot.

How This Applies to Your Understanding

Grasping the role of cementing is key to appreciating the craftsmanship behind a quality cowboy boot, whether you are buying one or learning to make one.

- If your primary focus is buying a quality boot: Recognize that a fully cemented lining is a hallmark of the traditional construction method that gives the boot its durability and clean interior finish.

- If your primary focus is learning bootmaking: Mastering the cementing process is a non-negotiable, foundational skill required to build a boot using the classic inside-out technique.

This single, often hidden, step is the bedrock upon which the entire structure and artistry of a traditional cowboy boot is built.

Summary Table:

| Function of Cementing | Key Benefit |

|---|---|

| Enables Inside-Out Assembly | Makes stitching side seams and decorative topstitching possible without bunching. |

| Provides Structural Strength | Creates a unified panel, preventing sagging and maintaining the boot's shape over time. |

| Ensures Precision Crafting | Offers a stable base for clean, professional stitching on the boot shaft. |

Need high-quality cowboy boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in traditional construction methods, including precise cementing techniques, ensures durable and well-crafted boots that meet the highest standards.

Contact us today to discuss your production needs and learn how we can bring value to your brand.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What factors should riders consider when choosing between laces and Velcro on motorcycle boots? Find Your Perfect Fit.

- Why is insulation important in snow boots? The Key to Warm, Dry Feet in Winter

- What are the main parts of a winter boot? A Guide to Warmth, Traction, and Protection

- Why is it important to wear walking boots at night? Protect Your Recovery While You Sleep

- What makes Chelsea boots unique? The Iconic Blend of Style, Comfort, and Versatility

- What materials are used for a walking shoe's upper? Choose the Right Balance for Your Walk

- What features do functional snow boots typically have? The 3 Essentials for Maximum Protection

- What are the different types of riding boots for English riding disciplines? Find Your Perfect Fit