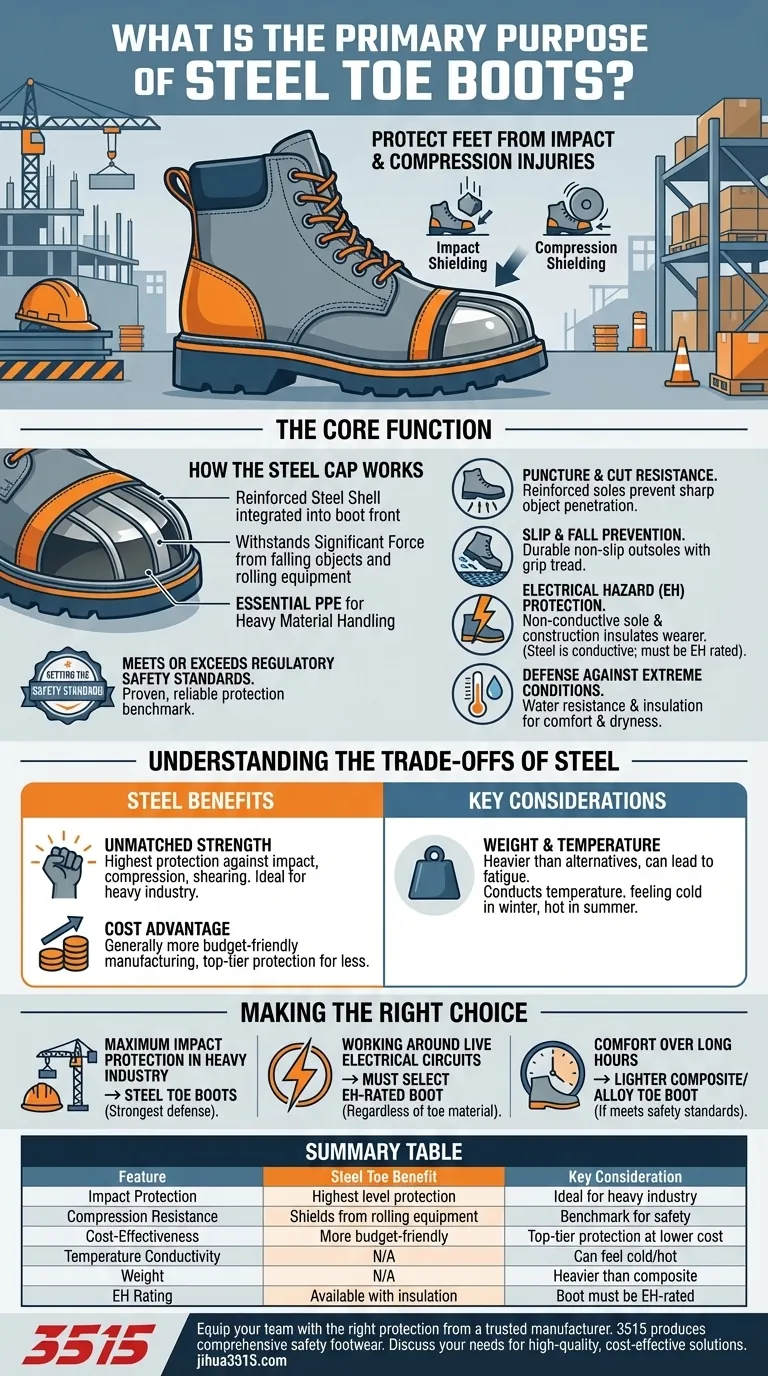

The primary purpose of a steel toe boot is to protect your feet from impact and compression injuries caused by falling objects or heavy rolling equipment. This is achieved through a reinforced steel cap built into the toe area, which acts as a critical shield in hazardous work environments like construction, manufacturing, and logistics.

While the steel cap provides essential impact protection, the boot itself is a complete safety system. Understanding the specific benefits and trade-offs of steel is key to selecting the right footwear for your specific workplace hazards.

The Core Function: Impact and Compression Shielding

The non-negotiable role of a steel toe boot is to prevent crushing injuries to the foot, which is one of the most common and debilitating workplace accidents.

How the Steel Cap Works

The reinforced steel toe cap is a protective shell integrated into the front of the boot. It is engineered to withstand significant force from both direct impacts (falling objects) and steady compression (rolling equipment).

This feature makes the boot an essential piece of Personal Protective Equipment (PPE) in any environment where heavy materials are handled.

Setting the Safety Standard

Steel toe boots are designed to meet or exceed specific safety standards set by regulatory bodies. Their ability to provide proven, reliable protection against impact and compression makes them a benchmark for workplace footwear safety.

Beyond the Toe: A Complete Safety System

While the steel cap is the defining feature, a high-quality work boot incorporates several other critical safety elements. The boot works as a unified system to protect the wearer from a wide range of potential dangers.

Puncture and Cut Resistance

Many safety boots feature reinforced soles that prevent sharp objects like nails or metal shards from piercing the bottom of the foot.

Slip and Fall Prevention

The outsoles are typically made from durable, non-slip materials with tread patterns designed to provide maximum grip on wet, oily, or uneven surfaces.

Protection from Electrical Hazards

This is a critical area of nuance. Steel itself is conductive. However, many steel toe boots are rated for Electrical Hazard (EH) protection. This safety rating comes from the non-conductive sole and overall construction of the boot, which insulates the wearer from the ground. The steel cap must be fully enclosed and not exposed.

Defense Against Extreme Conditions

Safety boots often include features like water resistance to keep feet dry and insulation to protect against extreme cold, ensuring both safety and comfort.

Understanding the Trade-offs of Steel

Steel is the traditional choice for safety toes, but it's important to understand its specific advantages and disadvantages compared to modern alternatives like composite or alloy toes.

The Benefit of Unmatched Strength

Steel toe caps offer the highest level of protection against impact, compression, and shearing forces. For heavy-duty industrial work, their strength is unparalleled.

The Downside of Weight and Temperature

Steel is heavier than composite or alloy materials, which can lead to fatigue over a long workday. It also readily conducts temperature, meaning the boots can feel cold in winter and hot in summer.

The Clear Cost Advantage

Generally, steel toe boots are less expensive to manufacture than those with composite or alloy toes. This often makes them a more budget-friendly option without compromising on top-tier impact protection.

Making the Right Choice for Your Goal

Selecting the correct boot depends entirely on the hazards of your specific job.

- If your primary focus is maximum impact protection in heavy industry: Steel toe boots offer the strongest and most reliable defense against crushing forces.

- If your primary focus is working around live electrical circuits: You must select a boot explicitly marked with an Electrical Hazard (EH) rating, regardless of the toe material.

- If your primary focus is comfort over long hours on your feet: A lighter-weight composite or alloy toe boot may be a better choice, provided it meets the required safety standards for your job site.

Ultimately, choosing the right boot means matching its specific safety features to the real-world risks you face every day.

Summary Table:

| Feature | Steel Toe Benefit | Key Consideration |

|---|---|---|

| Impact Protection | Highest level of protection against falling objects. | Ideal for heavy industry and construction. |

| Compression Resistance | Shields feet from heavy rolling equipment. | The benchmark for proven safety standards. |

| Cost-Effectiveness | Generally more budget-friendly than composite toes. | Offers top-tier protection at a lower cost. |

| Temperature Conductivity | N/A | Can feel cold in winter and hot in summer. |

| Weight | N/A | Heavier than composite alternatives, which may cause fatigue. |

| Electrical Hazard (EH) Rating | Available with proper insulation. | Boot must be specifically EH-rated; steel itself is conductive. |

Equip your team with the right protection from a trusted manufacturer.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We understand that the right boot is critical for safety and productivity. Our production capabilities encompass all types of steel toe and composite toe boots, ensuring you get durable, reliable, and compliant footwear tailored to your specific industry hazards.

Let's discuss your safety footwear needs. Contact our experts today for a consultation and discover how we can support your business with high-quality, cost-effective solutions.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the key features of a work boot? Essential Protection for Hazardous Work Environments

- What types of safety toe boots are available? Find the Perfect Fit for Your Job's Hazards

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- What causes corns in steel toe boots and how can they be prevented? Master the Perfect Fit to Avoid Pain

- Is there any truth to the myth about steel toe boots causing toe injuries upon impact? Debunking Common Safety Concerns